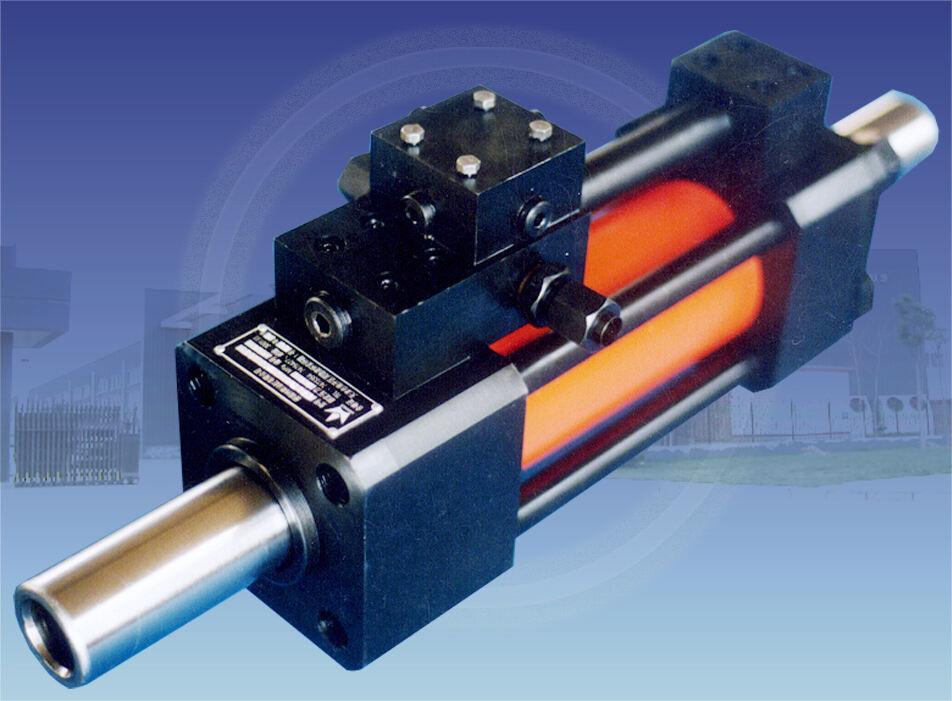

High-Pressure Hydraulic Cylinder Design for Demanding Metallurgical Applications

Challenges of High Pressure in Steel and Metal Processing

In metallurgy shops across the country, hydraulic cylinders regularly handle pressures well over 400 bar or about 5,800 psi. Forging presses and extrusion equipment typically need even higher specs sometimes pushing past 10,000 psi during operation. All this brute force takes its toll fast on cylinder components. Seals get worn down quicker than normal and those metal rods show surface damage after repeated cycles. The constant stress also makes barrel welds vulnerable to fatigue cracks developing over time. When things heat up during processing, thermal expansion becomes another headache for maintaining pressure integrity. Manufacturers have to maintain extremely tight tolerances around +/- 0.05 mm just to keep fluids from leaking past where they shouldn't.

Engineering Solutions for Sustained Pressure Performance

To tackle these issues, engineers have developed several improvements including multi stage piston seals, stronger barrel flanges, and welding patterns arranged in a staggered fashion which helps spread out stress points across components. Using finite element analysis or FEA as it's commonly called, manufacturers can fine tune how ports are shaped, cutting down on those annoying pressure spikes caused by turbulence inside the system by around 27% when compared with older cast designs. Another important safety feature comes in the form of dual pressure relief valves that act as backup systems during overload situations something absolutely necessary if we want to avoid total equipment failure during long running casting processes where stopping production isn't really an option.

Material Selection and Wall Thickness for Safety and Durability

High-pressure cylinders employ forged ASTM A519 steel barrels with yield strengths of 850 MPa, paired with case-hardened piston rods (60–62 HRC) for scratch resistance. Manufacturers now use computational models to calculate optimal wall thickness based on pressure demands:

| Pressure Rating | Minimum Wall Thickness (mm) | Safety Factor |

|---|---|---|

| 300 bar | 25 | 4:1 |

| 500 bar | 38 | 3.5:1 |

| 700 bar | 54 | 3:1 |

This data-driven approach ensures structural integrity while minimizing material over-engineering.

Case Study: Forging Press Cylinders Operating at 400 Bar

One major automotive parts manufacturer recently upgraded their massive 40 MN forging press with specially designed cylinders. These included toughened 42CrMo4 alloy barrels for strength, wireless sensors monitoring both pressure and temperature inside the rod glands, plus triple seals on the pistons backed by PTFE rings to prevent leaks. After implementing these changes, the company saw something remarkable happen - unplanned equipment downtime dropped dramatically by around 62% within just 18 months. Even more impressive was how well everything held up under extreme conditions. The system maintained less than 0.1% internal leakage at 400 bar pressure while enduring those intense 1,200 compression cycles every single day. Looking at oil samples after installation told another story too. There were 83% fewer iron particles floating around compared to before, which means the components are standing up much better to constant heavy use than they did previously.

Thermal Resilience in Hydraulic Cylinders for Extreme Temperature Environments

Impact of Molten Metal and Furnace Radiation on Cylinder Performance

In metallurgical settings, hydraulic cylinders are constantly battling extreme conditions. Temperatures around molten metal baths can go well beyond 300 degrees Celsius, and there's always that intense heat radiating from nearby furnaces. The result? Standard seal materials break down roughly 40 percent quicker compared to regular industrial setups. Steel piston rods aren't faring much better either, losing their tensile strength somewhere between half a percent to over one percent for every additional 50 degrees past 200°C. What makes matters worse is the radiant heat coming off casting lines, which speeds up surface oxidation by three times normal rates. All this means engineers need to think outside the box when designing these components if they want them to last through the punishing conditions.

Advanced Coatings and Seals for Thermal Stability

Thermal barrier coatings, or TBCs as they're commonly called, cut down on heat transfer to those vital parts by somewhere between 55% and 70%. These coatings work through their layered design, where ceramic top layers act as insulators while bond coats handle the tricky business of thermal expansion differences. When it comes to sealing materials that can stand the heat, perfluoroelastomer seals are pretty impressive stuff. They hold up well even at temperatures reaching around 315 degrees Celsius. Tests show these seals last four times longer than regular nitrile ones when put through accelerated aging conditions. Looking at what researchers have found so far, plasma sprayed yttria stabilized zirconia coatings make quite a difference too. During long periods in furnaces, surfaces treated with these coatings stay approximately 182 degrees cooler than untreated surfaces. This kind of performance makes all the difference in industrial applications where component longevity matters most.

Inconel, Ceramic Composites, and Heat Shield Technologies

| Material | Temperature Limit | Key Benefit |

|---|---|---|

| Inconel 718 | 700°C | Oxidation resistance |

| SiC-Si3N4 ceramic | 1,200°C | Near-zero thermal expansion |

| Carbon-carbon | 2,000°C | Rapid heat dissipation |

High-entropy ceramics like (HfTaZrNb)C retain 94% of room-temperature hardness at 1,000°C, making them ideal for piston rod coatings. Integrated heat shields with aerogel insulation lower internal hydraulic fluid temperatures by 80–100°C in ladle handling applications.

Case Study: Ladle Tilt Cylinders at 300°C Ambient Temperatures

One steel production facility saw service intervals triple when they upgraded their ladle tilt cylinder systems. The upgrades included special Inconel 625 piston rods treated with HVOF coating containing Cr3C2-NiCr material. They also installed gland seals impregnated with ceramics capable of handling temperatures up to 330 degrees Celsius. Multi layer insulation blankets helped cut down external surface temps dramatically from around 285 to just 67 degrees Celsius. After tracking performance for nearly 18 months straight, maintenance records showed remarkable results too. Seal replacements dropped by roughly 82 percent while instances of rod galling decreased by almost 80%. These improvements translated into significant cost savings and less downtime for repairs during regular operations.

Long-Stroke Hydraulic Cylinder Systems for Metallurgical Machinery

Extended Displacement Needs in Rolling Mills and Extrusion Presses

In today's metalworking operations, hydraulic cylinders need pretty long strokes, often over 1.5 meters, just to handle those big billets in aluminum extrusion lines or manage slab deformation in steel rolling mills. The real challenge comes when these systems have to keep delivering consistent force throughout their entire range of motion. Hot rolling mills typically run around 12 cycles per minute, and nobody wants to see velocity drop off halfway through a stroke. That's why most facilities invest in advanced hydraulic controls these days. We're talking about things like multi stage accumulator banks paired with pressure compensated flow valves. These setups help maintain that crucial 350 bar operating pressure right up until the cylinder reaches full extension. Makes all the difference in production efficiency and equipment longevity.

Buckling Resistance and Column Strength in Long-Stroke Designs

When stroke-to-diameter ratios exceed about 20:1, there's a real risk of buckling problems. To deal with this issue, engineers turn to several strategies. They often use high strength materials such as 34CrMo4 which has around 1,100 MPa tensile strength. Another approach is increasing the barrel diameter, typically going beyond 320mm when dealing with strokes over 2 meters long. Some designs incorporate compound walls where the inside is precision honed and the outside layer is forged steel, giving better resistance against twisting forces. All these improvements result in roughly 28% greater capacity before buckling occurs. This means equipment can handle up to 18 MN of axial force during continuous casting operations without failure, making them much more dependable in industrial settings.

Guided Stroke Systems and Intermediate Support Bearings

Rail-guided stroke assemblies with 0.05 mm/m alignment tolerance prevent side-load deflection in 4-high rolling mills. Mid-span support bearings, spaced at 1.2 piston diameter intervals, reduce unsupported length effects and cut lateral vibration amplitudes by 73% (SAE J1467). Integrated wear sensors enable predictive maintenance, extending service intervals by 400 operating hours between replacements.

Case Study: 2-Meter Stroke Cylinder in Aluminum Extrusion Line

A smelter operation in North America recently gave their 25 meganewton extrusion press a major overhaul, installing custom made cylinders with a 2 meter stroke. These new components include a dual gland design along with tapered roller bearings, while the piston rods are crafted from 4140 alloy steel hardened all the way to 60 HRC. They also added a special 12 point support system right in the middle of the stroke path. After putting these upgrades into action, maintenance records indicate roughly 25 percent longer time between necessary overhauls. What's even more impressive is that they've managed to keep positional accuracy within just 0.2 millimeters despite working temperatures reaching up to 700 degrees Celsius on those die faces. This has translated into better material usage overall, with billet utilization now sitting at around 98.5 percent efficiency.

Custom Integration and Durability Optimization of Hydraulic Cylinders

Modular and Custom-Built Cylinders for Plant-Specific Layouts

Steel mills and other metalworking plants typically work around limited space and old machinery setups, which means their hydraulic cylinders need to fit into whatever layout exists. The modular approach solves this problem pretty well since these systems can be mounted in different ways and assembled step by step, saving quite a bit of time during installation in those cramped factory areas. When standard equipment just won't do, custom made hydraulic units handle all sorts of unusual requirements like odd force directions, special material movement patterns, and easy access points for regular maintenance checks. These specialized solutions make sure everything works smoothly together without sacrificing performance simply because something had to be modified from what came out of the box originally.

Retrofitting and OEM Collaboration for Seamless Integration

Collaboration between OEMs and plant operators streamlines cylinder retrofits. Joint design protocols use digital simulations to verify fitment, reducing commissioning delays caused by compatibility issues. Standardized interface plates and mounting systems ensure new cylinders align with existing hydraulic architectures, addressing a key cause of project setbacks.

Predictive Maintenance and Condition Monitoring for Longevity

Embedded IoT sensors monitor lubrication viscosity and rod seal degradation in real time, supporting data-driven maintenance planning. Machine learning algorithms analyze pressure transients to predict failure windows with ±3% accuracy. This proactive strategy extends cylinder service life by 20–35% and reduces unplanned downtime by 60% compared to time-based maintenance schedules.

FAQ Section

What are high-pressure hydraulic cylinders used for?

High-pressure hydraulic cylinders are commonly used in demanding applications within metallurgy, such as forging presses, extrusion equipment, and rolling mills. They handle extreme pressures to facilitate processes like metal shaping and deformation.

How do engineers manage thermal expansion in hydraulic cylinders?

Engineers manage thermal expansion by employing advanced coatings, seals, and material choices that mitigate the effects of heat. Technologies such as thermal barrier coatings and perfluoroelastomer seals play crucial roles in maintaining cylinder functionality under high temperatures.

What materials improve buckling resistance in long-stroke cylinders?

Materials like 34CrMo4 and designs incorporating compound walls are used to improve buckling resistance in long-stroke cylinders. These approaches significantly enhance the cylinder's ability to withstand axial forces during operations.

How can predictive maintenance extend the life of hydraulic cylinders?

Predictive maintenance leverages IoT sensors and machine learning algorithms to monitor the condition of hydraulic cylinders in real time. This data-driven approach predicts failure windows accurately, allowing for timely interventions that extend equipment lifespan and reduce downtime.

Table of Contents

- High-Pressure Hydraulic Cylinder Design for Demanding Metallurgical Applications

- Thermal Resilience in Hydraulic Cylinders for Extreme Temperature Environments

- Long-Stroke Hydraulic Cylinder Systems for Metallurgical Machinery

- Custom Integration and Durability Optimization of Hydraulic Cylinders

- FAQ Section