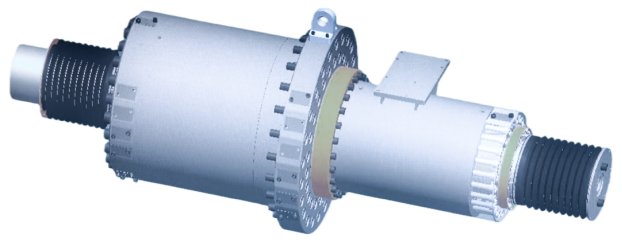

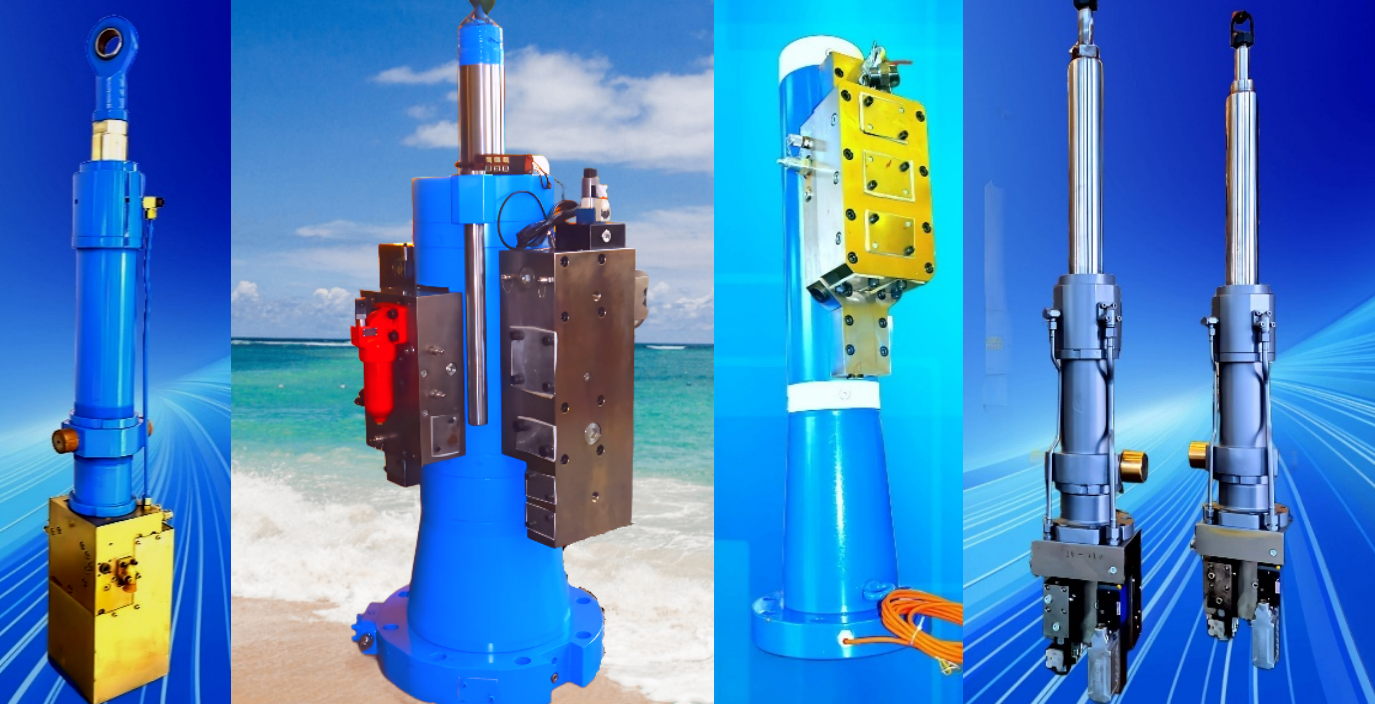

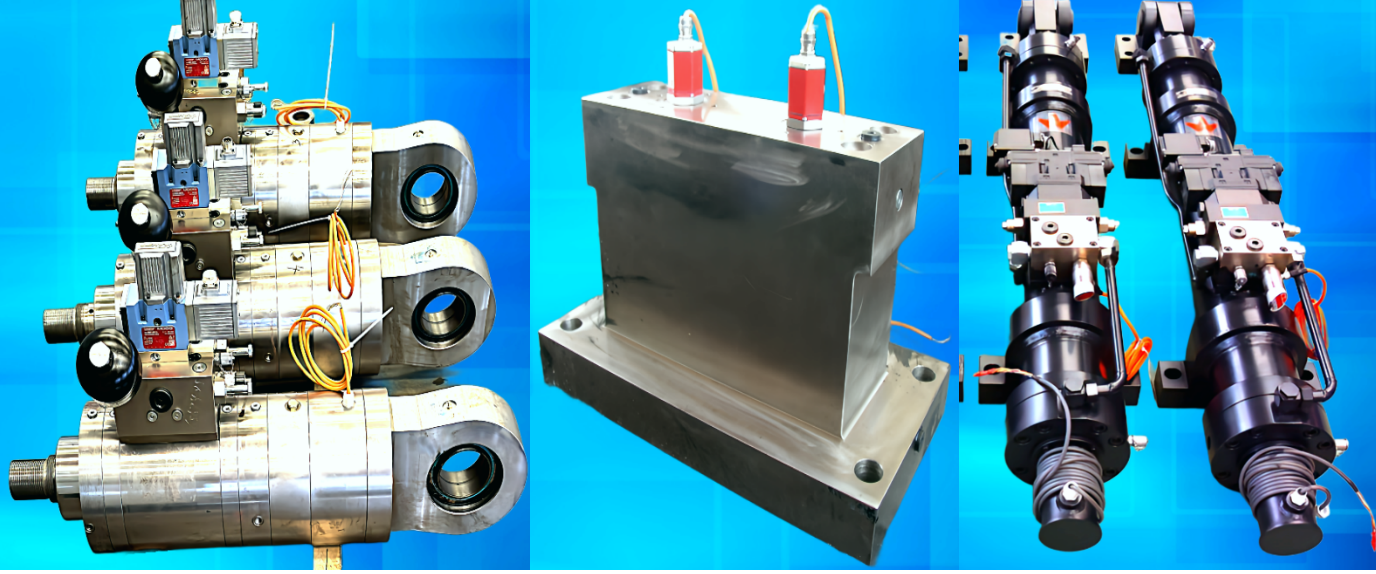

Foto del Cilindro Idraulico Servo

Cilindro Idraulico Servo

Alta Precisione · Alte Prestazioni Dinamiche · Alta Affidabilità

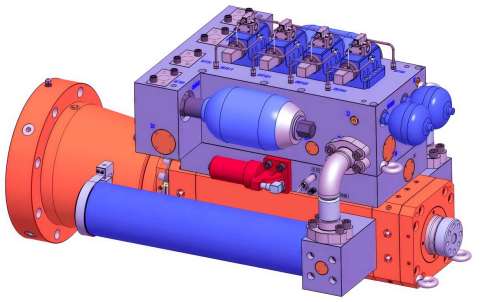

Un Cilindro Idraulico Servo è un attuatore completamente controllato in ciclo chiuso che integra un corpo cilindro di precisione, un insieme di sensori ad alte prestazioni, una valvola servo-elettroidraulica e un controllore intelligente.

Fornisce un controllo continuo, in tempo reale e altamente accurato della posizione, velocità e forza, fungendo da nucleo unificato di Sensing – Decisione – Esecuzione in apparecchiature moderne e avanzate.

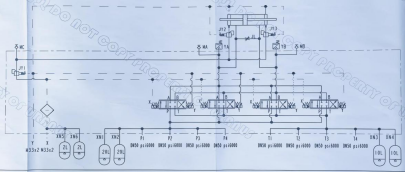

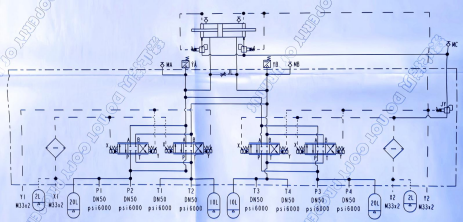

1. Architettura di Controllo a Loop Chiuso Multidimensionale

1.1 Controllo in Posizione e Velocità a Loop Chiuso

In base ai requisiti di precisione, velocità e ambiente, possono essere configurati diversi trasduttori di spostamento:

1.2 Controllo Chiuso in Forza e Pressione

・ Sensori di Pressione (Monitoraggio della Pressione in Camera)

Installati nella camera dello stelo e/o del cappuccio. La forza è calcolata come pressione × area del pistone. Ampia diffusione in processi AGC, pressatura e regolazione della forza.

・ Celle di Carico (Sensori di Forza all'Estremità dello Stelo)

Misurazione diretta della forza di spinta/trazione con la massima accuratezza. Ideale per test sui materiali e carichi di fatica.

1.3 Controllo Multi-Modalità e Ibrido

I sistemi servo avanzati supportano il passaggio o la combinazione senza interruzioni di più modalità di controllo all'interno di un singolo ciclo operativo:

・ Passaggio da Posizione a Forza

Esempio: assemblaggio robotico per interferenza/pressatura

Avvicinamento rapido in modalità posizione → transizione automatica alla modalità forza al contatto → inserimento a forza costante per evitare inceppamenti o danni.

・ Controllo Ibrido Forza–Posizione

Esempio: cilindri AGC nei laminatoi

Sia l'interasse dei rulli (posizione) che la forza di laminazione devono essere controllati con precisione per ottenere una regolazione accurata dello spessore.

2. Vantaggi tecnici

・Precisione Massima

Posizionamento a livello di micron, controllo stabile della velocità e regolazione altamente precisa della forza.

・Alta risposta dinamica

Tempo di risposta a livello di millisecondi per soddisfare applicazioni industriali ad alta velocità e ad alto tasso di accelerazione.

・Elevata densità di potenza

Erede dei vantaggi fondamentali della trasmissione idraulica, in grado di erogare facilmente forze di decine fino a centinaia di tonnellate.

・Efficienza energetica

Quando abbinato a un gruppo servo-pompa, il consumo energetico può essere significativamente ridotto rispetto ai sistemi convenzionali comandati a valvola.

・Flessibilità e intelligenza

I profili di movimento e le modalità di controllo possono essere riconfigurati tramite software: un solo attuatore adatto a più processi tecnologici.

Ideale per la produzione flessibile, le fabbriche intelligenti e i sistemi di gemello digitale.

3. Campi di applicazione: Potenziamento delle apparecchiature avanzate

Attrezzature metallurgiche

・Linee di colata continua e laminazione

・Oscillatore dello stampo

・Cilindri AGC (Controllo Automatico dello Spessore)

・Sollevamento degli elettrodi per forno elettrico ad arco

・Allineamento, centratura e posizionamento di precisione servocontrollati

Montaggio intelligente a pressione e assemblaggio

・Montaggio con interferenza di motori, cuscinetti, ingranaggi

・Monitoraggio completo delle curve forza-spostamento per garantire la qualità dell'assemblaggio

Prove di materiali e strutture

・Macchine per prove di fatica

・Macchine universali di prova

・Simulazione dello spettro di carico complesso

Formatura dei metalli

・Punzonatura, piegatura e goffratura di precisione

・Controllo a ciclo chiuso della forza di formatura e della profondità

Piattaforme di simulazione e movimento

・Simulatori di volo

・Piattaforme di simulazione sismica

・Attuatori dinamici multi-DOF

Robotica pesante

・Giunti ad alta precisione per grandi robot collaborativi

・Operazioni ad alta forza con controllo fine stabile

Prove a terra nel settore aerospaziale

・Simulazione dell'estensione/ritrazione del carrello d'atterraggio

・Simulazione del carico sulle superfici di controllo di volo

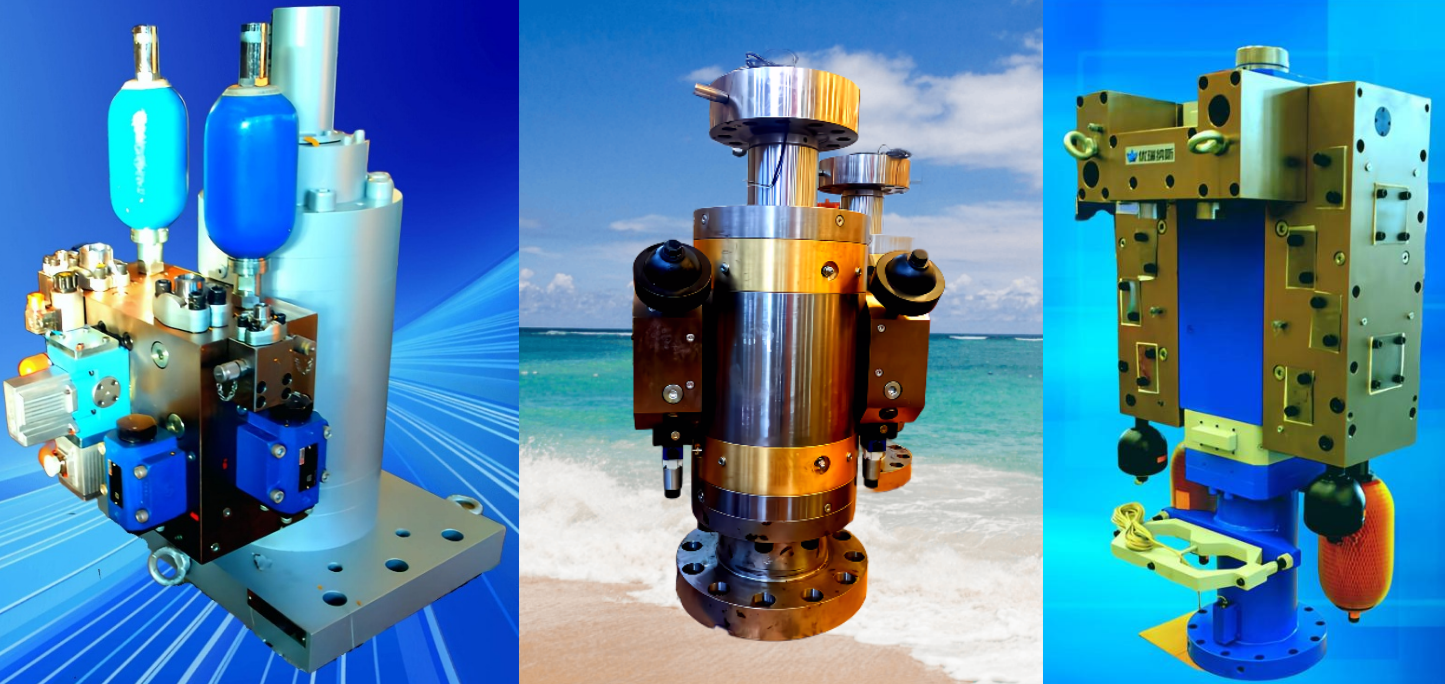

4. URANUS – Esperto globale in cilindri servo-idraulici personalizzati

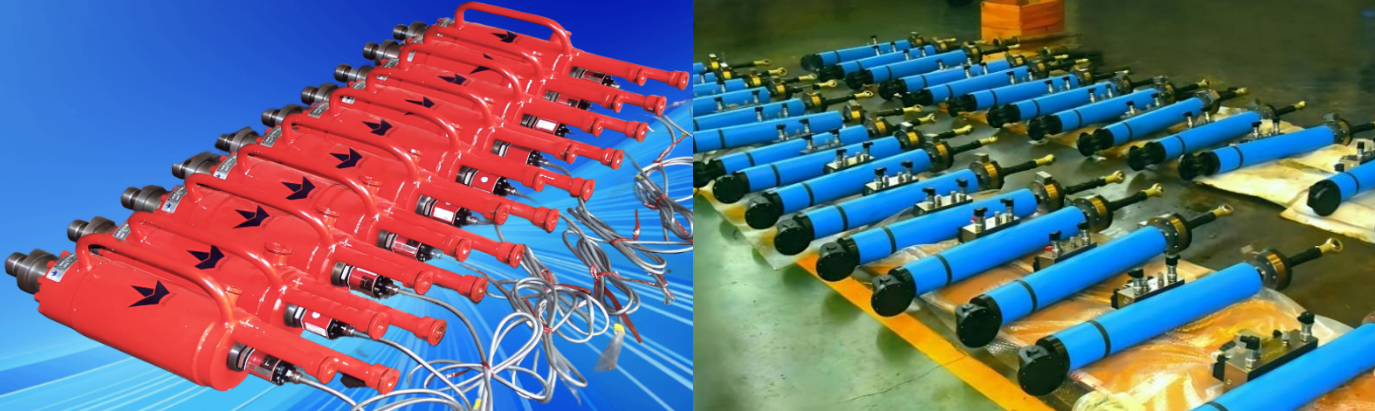

Dal suo insediamento, Tianjin Uranus Hydraulic Machinery Co., Ltd. ha progettato, sviluppato e prodotto con successo centinaia di modelli di cilindri servo-idraulici personalizzati e oltre diecimila unità per clienti nei settori della metallurgia, aerospaziale, apparecchiature per prove, robotica, produzione automobilistica e molti altri settori industriali.

URANUS offre:

・Elevata capacità ingegneristica non standard e di personalizzazione

・Centri di lavorazione di precisione avanzata e attrezzature per la lavorazione su larga scala

・Possiamo produrre aste pistoni con materiali superficiali sinterizzati come carburo di tungsteno (WC), carburo di silicio (SiC), ossido di alluminio (Al2O3), nitruro di silicio (Si3N4) e ossido di zirconio (ZrO2), nonché in acciaio legato e acciaio inossidabile, per soddisfare diverse condizioni operative speciali.

・Piattaforme complete di controllo e test servo

・Tracciabilità completa della qualità e rigorosi standard di ispezione

Invitiamo partner globali a collaborare nella realizzazione di cilindri servo personalizzati, attuatori idraulici ad alta precisione e sistemi servo-elettroidraulici OEM/ODM.

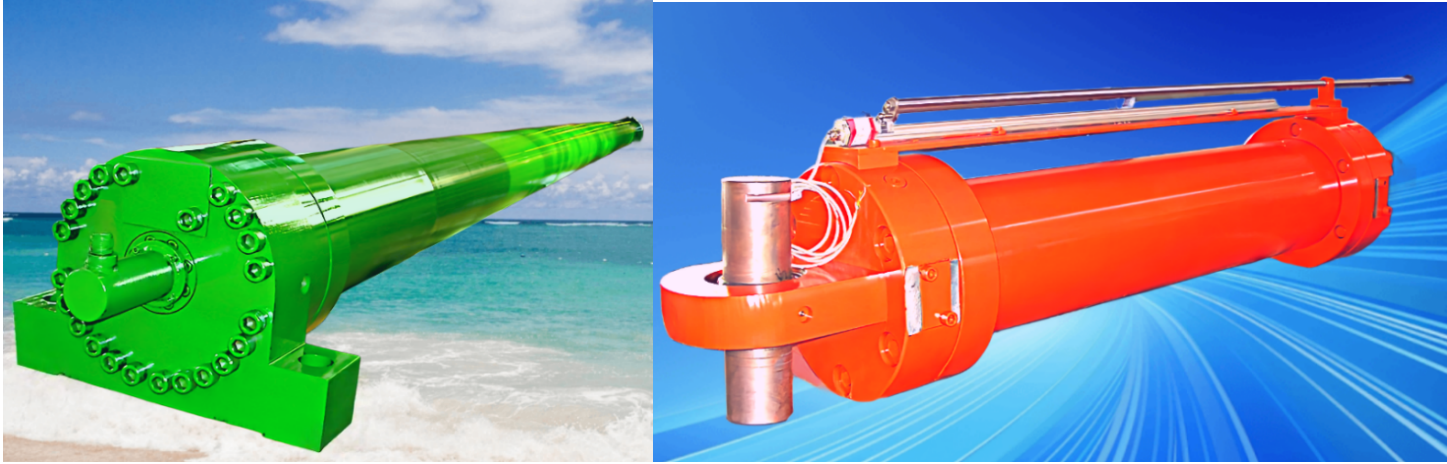

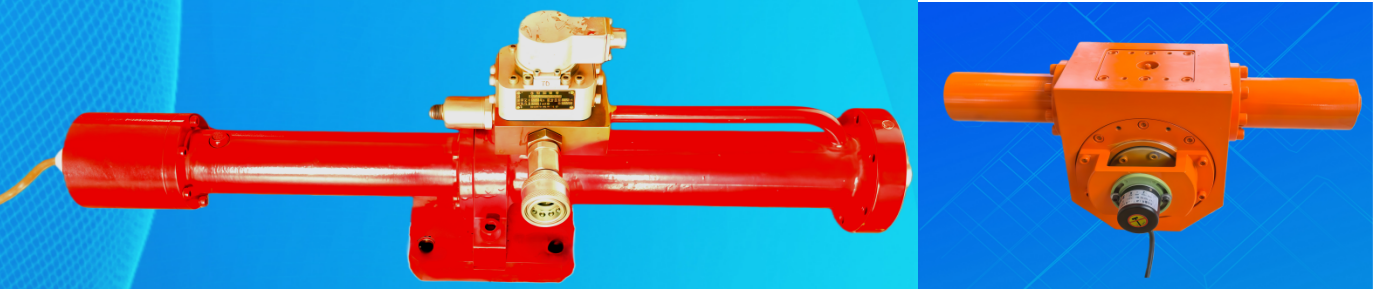

Esempi di prodotto

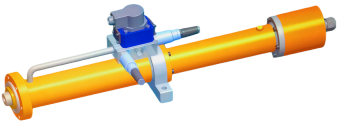

1. Nome: Cilindro Idraulico Servo per Vibrazioni; Modello: USYJ220/160-500LH

Alesaggio: 220 mm; Asta: 160 mm; Corsa: 500 mm; Corsa ammortizzata: 50 mm

Pressione di lavoro: 28 MPa; Pressione di prova: 35 MPa; Pressione di avviamento ≤ 0,2 MPa

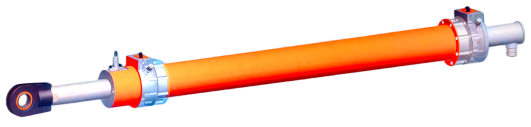

2. Nome: Cilindro Idraulico Servo per Vibrazioni; Modello: USYR220/160-500LH

Alesaggio: 220 mm; Asta: 160 mm; Corsa: 500 mm; Corsa ammortizzata: 50 mm

Pressione di lavoro: 28 MPa; Pressione di prova: 35 MPa; Pressione di avviamento ≤ 0,2 MPa

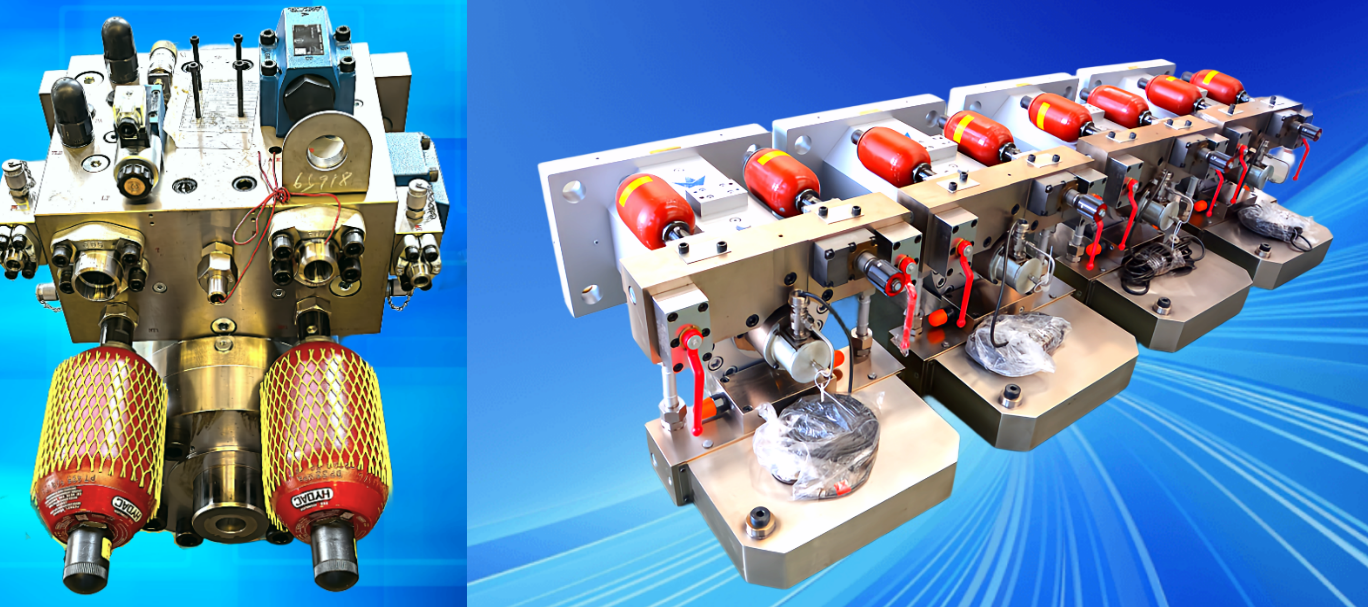

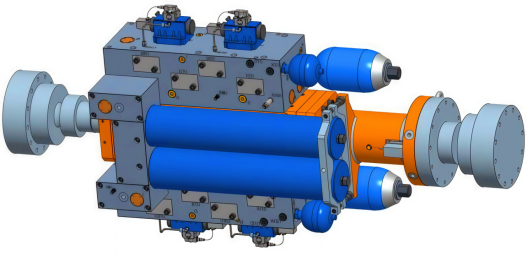

3. Nome: Attuatore Idraulico Composito Triplo Cilindro con Centraggio Integrato;

Modello: USYQ225/195-32+140/50-32HA+FK

Cilindro vibrante: Alesaggio 225 mm; Asta 195 mm; Corsa ±16 mm; Corsa ammortizzata 50 mm

Pressione di esercizio 21 MPa; Pressione di prova 32 MPa; Frequenza di vibrazione 200 Hz

Cilindro centraggio integrato: Alesaggio 140 mm; Asta 50 mm; Corsa ±16 mm; Corsa ammortizzata 50 mm

Pressione di esercizio 21 MPa; Pressione di prova 32 MPa

Cilindro di bilanciamento: Diametro pistone 220 mm; Area lato asta 8149 mm²; Area anulare 38013 mm²

4.Nome: Cilindro idraulico servo oscillante a pignone e cremagliera; Modello: UBFKD40-90°

Alesaggio: 40 mm; Angolo di oscillazione 90°; Frequenza di vibrazione 50 Hz; Ampiezza ±3°

Sensore esterno di spostamento angolare

Pressione di esercizio: 14 MPa; Pressione di prova: 21 MPa; Coppia nominale in uscita 770 N·m

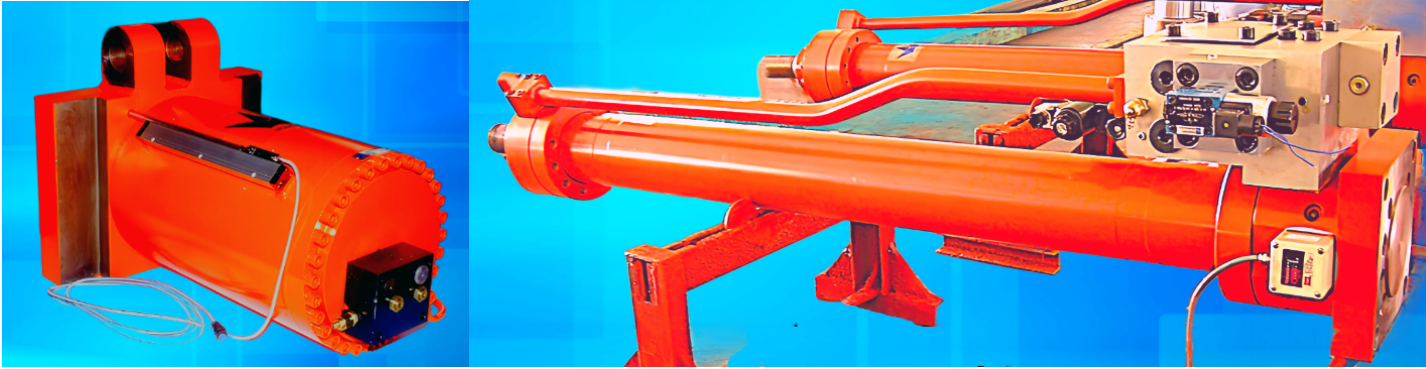

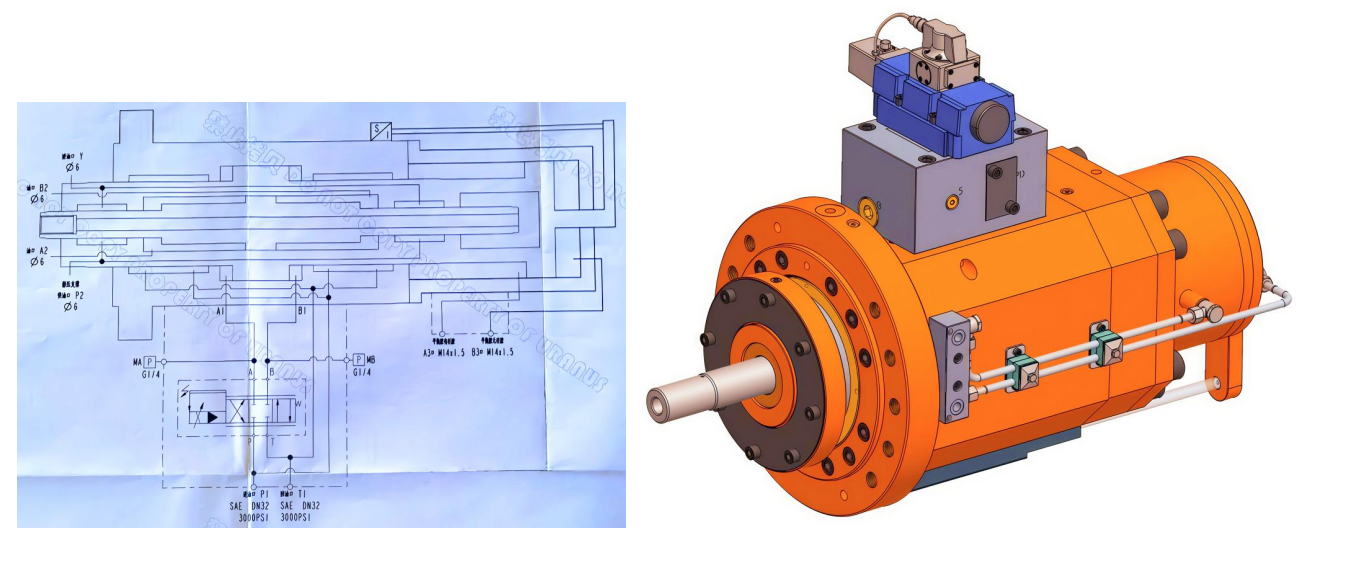

5.Nome: Cilindro Idraulico Servo; Modello: UGDT40/28-200

Alesaggio: 40 mm; Aste: 28 mm; Corsa ±100 mm; Frequenza di vibrazione 200 Hz; Ampiezza ±1–10 mm

Pressione di esercizio: 16 MPa; Pressione di prova: 24 MPa

Sensore di spostamento integrato, Valvola servo installata

6.Nome: Cilindro Idraulico Servo ad Alta Temperatura; Modello: UYS100/70-1100

Alesaggio: 100 mm; Aste: 70 mm; Corsa 1100 mm

Sensore di spostamento integrato; Sensore di spostamento magnetostrittivo all'estremità della barra del pistone

Pressione di esercizio: 16 MPa; Pressione di prova: 24 MPa

7.Nome: Cilindro Idraulico Servo per Macchina di Prova alla Fatica dei Materiali; Modello: UYSTD800+500/360-620

Alesaggio: Cilindro grande 800 mm; Cilindro piccolo 500 mm; Aste 360 mm; Corsa ±305 mm

Pressione di esercizio: 23 MPa; Pressione di prova: 37,5 MPa; Pressione di avviamento ≤ 0,1 MPa

Sensore di spostamento integrato; Frequenza di vibrazione 1–10 Hz