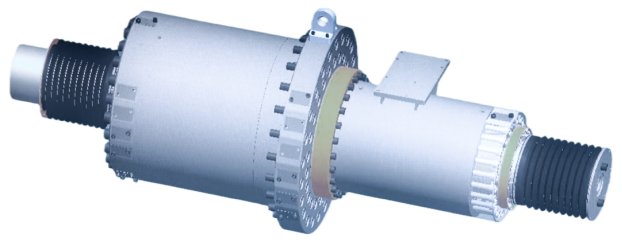

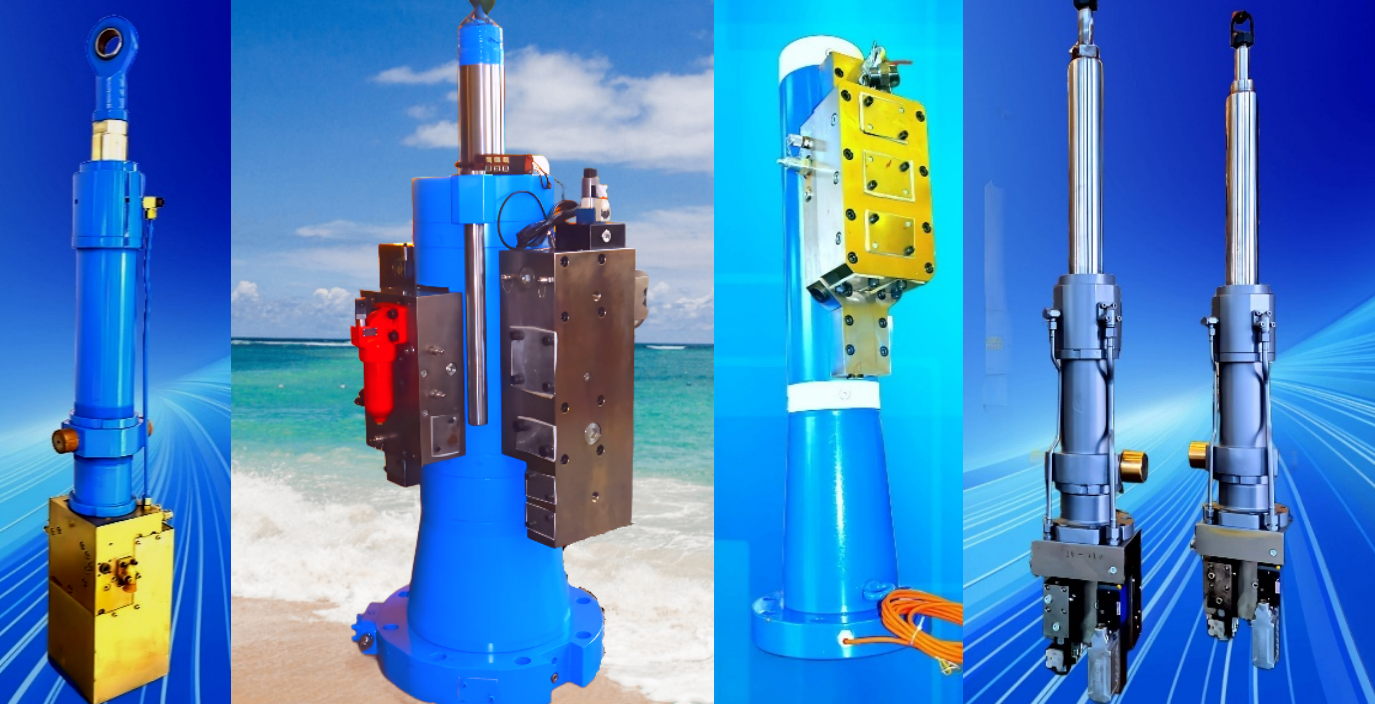

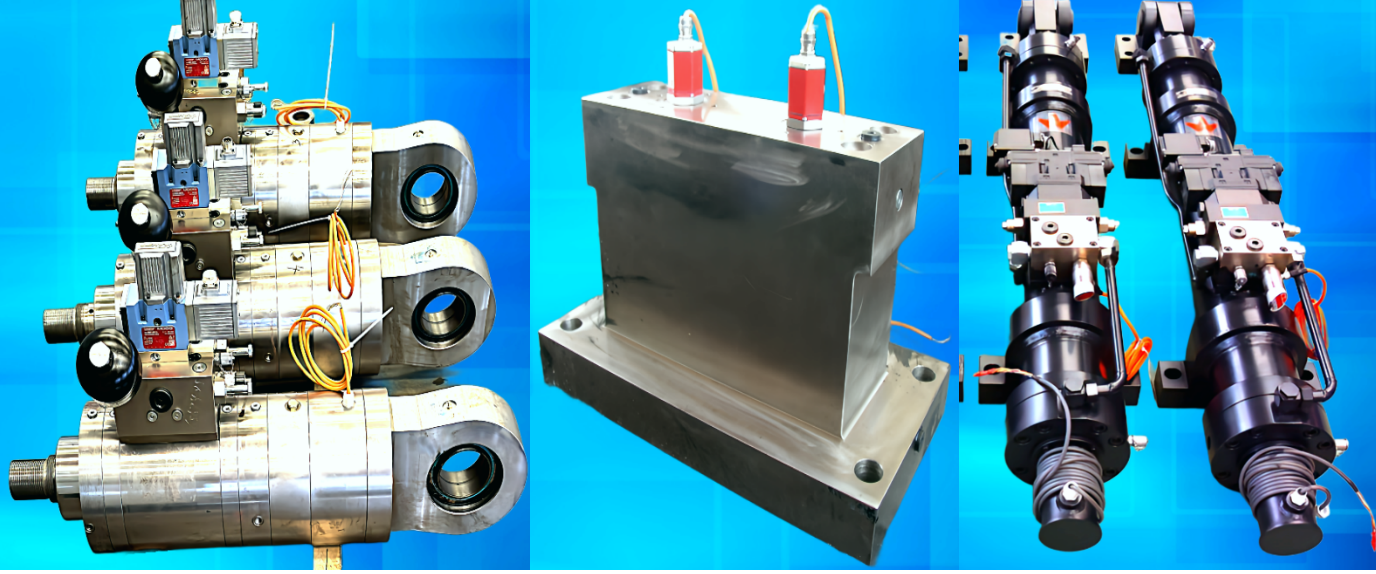

सर्वो हाइड्रोलिक सिलेंडर की तस्वीर

सर्वो हाइड्रॉलिक सिलिंडर

उच्च परिशुद्धता · उच्च गतिशीलता · उच्च विश्वसनीयता

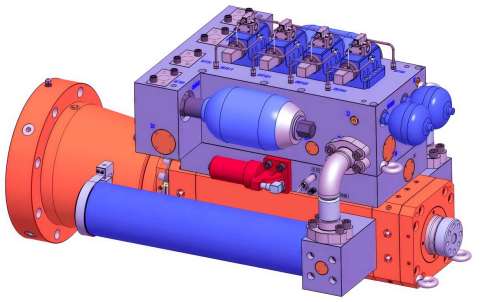

एक सर्वो हाइड्रोलिक सिलेंडर एक पूर्णतः बंद-लूप नियंत्रित एक्चुएटर है जो एकीकृत करता है परिशुद्ध सिलेंडर बॉडी, उच्च-प्रदर्शन सेंसर सूट, इलेक्ट्रो-हाइड्रोलिक सर्वो वाल्व, और बुद्धिमान नियंत्रक।

यह निरंतर, वास्तविक समय में और अत्यधिक सटीक नियंत्रण प्रदान करता है स्थिति, वेग और बल का एकीकृत मुख्य केंद्र के रूप में कार्य करता है सेंसिंग – निर्णय – क्रियान्वयन आधुनिक उन्नत उपकरणों में।

1. बहु-आयामी क्लोज़्ड-लूप नियंत्रण आर्किटेक्चर

1.1 स्थिति और वेग क्लोज़्ड-लूप नियंत्रण

शुद्धता, गति और पर्यावरणीय आवश्यकताओं के अनुसार, विभिन्न विस्थापन ट्रांसड्यूसर कॉन्फ़िगर किए जा सकते हैं:

1.2 बल एवं दबाव संवृत-लूप नियंत्रण

・ दबाव सेंसर (चैम्बर दबाव निगरानी)

छड़ और/या कैप चैम्बर में स्थापित। बल की गणना दबाव × पिस्टन क्षेत्र के आधार पर की जाती है। एजीसी, प्रेस-फिट और बल-नियमित प्रक्रियाओं में व्यापक रूप से उपयोग किया जाता है।

・ लोड सेल (छड़-सिरे के बल सेंसर)

धक्का/खींच के बल का सीधा मापन, उच्चतम सटीकता के साथ। सामग्री परीक्षण और थकान भारण के लिए आदर्श।

1.3 मल्टी-मोड और हाइब्रिड नियंत्रण

उन्नत सर्वो सिस्टम एक ही संचालन चक्र के भीतर कई नियंत्रण मोड के स्वच्छंद स्विचिंग या मिश्रण का समर्थन करते हैं:

・ स्थिति → बल स्विचिंग नियंत्रण

उदाहरण: रोबोटिक इंटरफेरेंस/प्रेस-फिट असेंबली

स्थिति मोड में त्वरित संवाद → संपर्क पर स्वतः बल मोड में संक्रमण → अटकने या क्षति से बचने के लिए स्थिर-बल सम्मिलन।

・ हाइब्रिड बल–स्थिति नियंत्रण

उदाहरण: रोलिंग मिलों में AGC सिलेंडर

सटीक मोटाई नियमन प्राप्त करने के लिए रोल गैप (स्थिति) और रोलिंग बल दोनों को सटीक रूप से नियंत्रित किया जाना चाहिए।

2. तकनीकी लाभ

・अंतिम सटीकता

माइक्रॉन-स्तर की स्थिति निर्धारण, स्थिर वेग नियंत्रण और अत्यधिक सटीक बल विनियमन।

・उच्च गतिशील प्रतिक्रिया

उच्च गति, उच्च त्वरण वाले औद्योगिक अनुप्रयोगों को पूरा करने के लिए मिलीसेकंड-स्तरीय प्रतिक्रिया समय।

・उच्च शक्ति घनत्व

हाइड्रोलिक संचरण के मौलिक लाभों को अपनाता है, आसानी से दसियों से लेकर सैकड़ों टन तक का निर्गत बल प्रदान कर सकता है।

・ऊर्जा दक्षता

जब सर्वो पंप इकाई के साथ संयोजित किया जाता है, तो पारंपरिक वाल्व-नियंत्रित प्रणालियों की तुलना में ऊर्जा खपत में महत्वपूर्ण कमी लाई जा सकती है।

・लचीलापन एवं बुद्धिमत्ता

मोशन प्रोफाइल और नियंत्रण मोड को सॉफ्टवेयर के माध्यम से पुनः कॉन्फ़िगर किया जा सकता है—एक ऐक्चुएटर कई तकनीकी प्रक्रियाओं के लिए उपयुक्त।

लचीले उत्पादन, स्मार्ट कारखानों और डिजिटल ट्विन प्रणालियों के लिए आदर्श।

3. अनुप्रयोग क्षेत्र: उन्नत उपकरणों को सशक्त बनाना

धातुकर्म उपकरण

・निरंतर ढलाई और रोलिंग लाइनें

・मोल्ड ऑसिलेटर

・एजीसी (ऑटोमैटिक गेज कंट्रोल) सिलेंडर

・ईएएफ के लिए इलेक्ट्रोड उठाना

・सर्वो संरेखण, केंद्रीकरण और परिशुद्ध स्थिति निर्धारण

बुद्धिमान प्रेस-फिट और असेंबली

・इंजन, बेयरिंग, गियर की इंटरफेरेंस असेंबली

・असेंबली की गुणवत्ता सुनिश्चित करने के लिए बल-विस्थापन वक्रों की पूर्ण निगरानी

सामग्री और संरचनात्मक परीक्षण

・थकान परीक्षण मशीनें

・सार्वभौमिक परीक्षण मशीनें

・जटिल भार स्पेक्ट्रम अनुकरण

धातु निर्माण

・परिशुद्धता छापाखाने, मोड़ने, उभार बनाने

・आकार देने के बल और गहराई का बंद-लूप नियंत्रण

अनुकरण और गति चलन तल

・उड़ान अनुकरण यंत्र

・भूकंप अनुकरण मंच

・बहु-DOF गतिशील एक्चुएटर

भारी उपकरण रोबोटिक्स

・बड़े सहयोगी रोबोट्स के लिए उच्च-परिशुद्धता संयुक्त

・स्थिर सूक्ष्म नियंत्रण के साथ उच्च-बल संचालन

एयरोस्पेस ग्राउंड परीक्षण

・लैंडिंग गियर एक्सटेंशन/रिट्रैक्शन अनुकरण

・फ्लाइट नियंत्रण सतह भार अनुकरण

4. यूरेनस – कस्टम सर्वो हाइड्रोलिक सिलेंडर में वैश्विक विशेषज्ञ

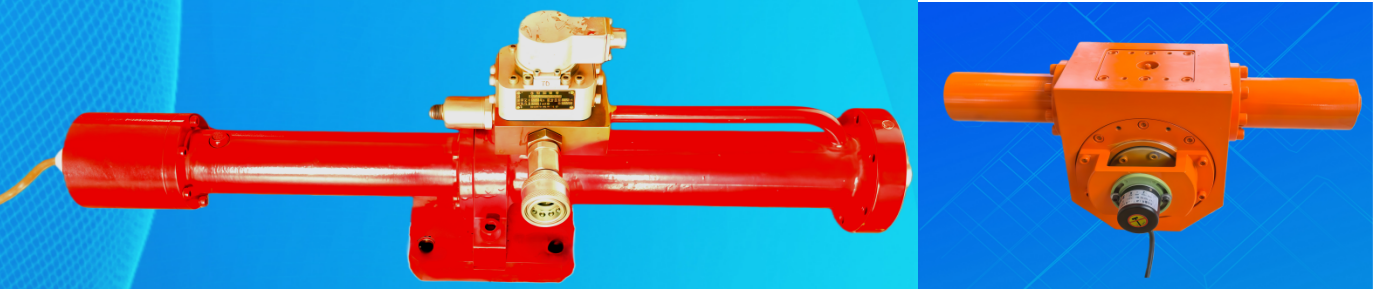

अपने स्थापना के बाद से, टियानजिन यूरेनस हाइड्रोलिक मशीनरी कंपनी लिमिटेड सफलतापूर्वक डिज़ाइन, इंजीनियरिंग और निर्माण किया है सैकड़ों कस्टम सर्वो हाइड्रोलिक सिलेंडर मॉडल और दस हजार से अधिक इकाइयाँ धातुकर्म, एयरोस्पेस, परीक्षण उपकरण, रोबोटिक्स, ऑटोमोटिव निर्माण, और अन्य कई उद्योगों में ग्राहकों के लिए।

यूरेनस प्रदान करता है:

・मजबूत गैर-मानक इंजीनियरिंग एवं अनुकूलन क्षमता

・उन्नत शुद्धता युक्त मशीनिंग केंद्र और बड़े पैमाने के प्रसंस्करण उपकरण

・हम टंगस्टन कार्बाइड (WC), सिलिकॉन कार्बाइड (SiC), एल्युमीनियम ऑक्साइड (Al2O3), सिलिकॉन नाइट्राइड (Si3N4), और ज़िरकोनियम ऑक्साइड (ZrO2) जैसी सिंटर की गई सतह सामग्री के साथ-साथ मिश्र धातु इस्पात और स्टेनलेस स्टील से पिस्टन रॉड बना सकते हैं, जो विभिन्न विशेष परिचालन स्थितियों को पूरा करते हैं।

・व्यापक सर्वो नियंत्रण और परीक्षण मंच

・पूर्ण गुणवत्ता-ट्रेसिबिलिटी और कठोर निरीक्षण मानक

हम अनुकूलित सर्वो सिलेंडर, उच्च-शुद्धता द्रवचालित एक्चुएटर और OEM/ODM इलेक्ट्रो-हाइड्रोलिक सर्वो सिस्टम पर वैश्विक साझेदारों का स्वागत करते हैं।

उत्पाद उदाहरण

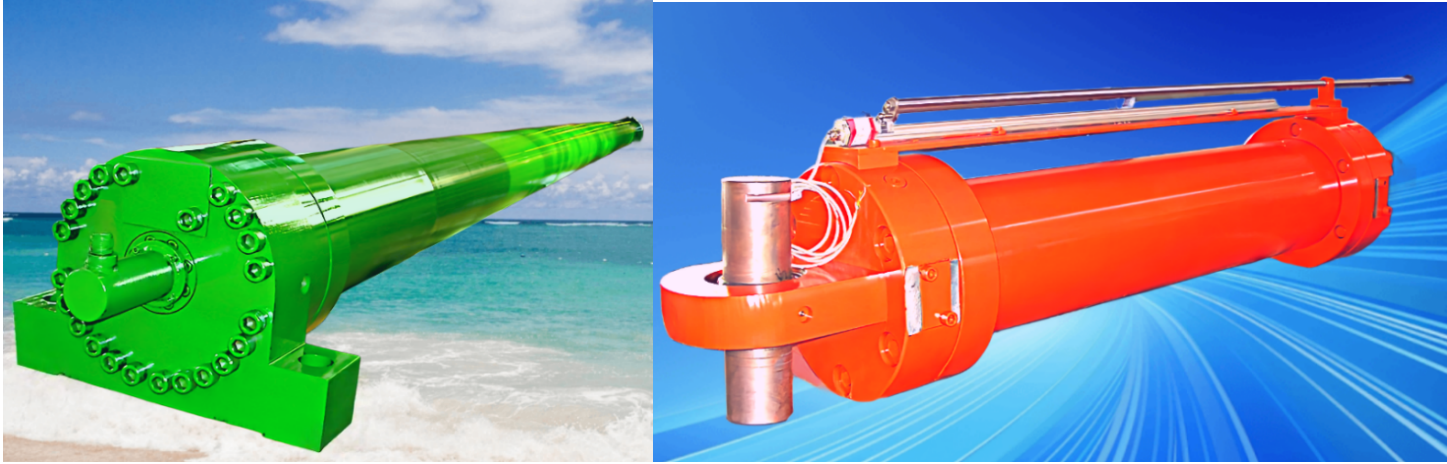

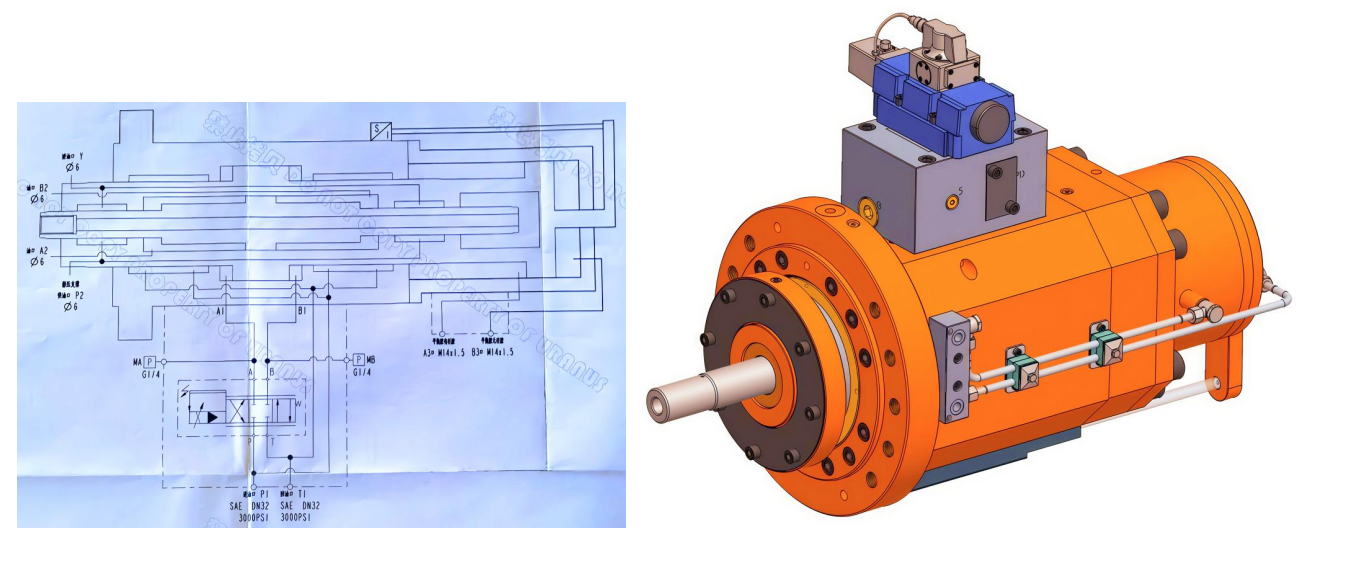

1.नाम: सर्वो कंपन हाइड्रोलिक सिलेंडर; मॉडल: USYJ220/160-500LH

बोर: 220 मिमी; रॉड: 160 मिमी; स्ट्रोक: 500 मिमी; कुशन स्ट्रोक: 50 मिमी

कार्यकारी दबाव: 28 MPa; परीक्षण दबाव: 35 MPa; प्रारंभिक दबाव ≤ 0.2 MPa

2.नाम: सर्वो कंपन हाइड्रोलिक सिलेंडर; मॉडल: USYR220/160-500LH

बोर: 220 मिमी; रॉड: 160 मिमी; स्ट्रोक: 500 मिमी; कुशन स्ट्रोक: 50 मिमी

कार्यकारी दबाव: 28 MPa; परीक्षण दबाव: 35 MPa; प्रारंभिक दबाव ≤ 0.2 MPa

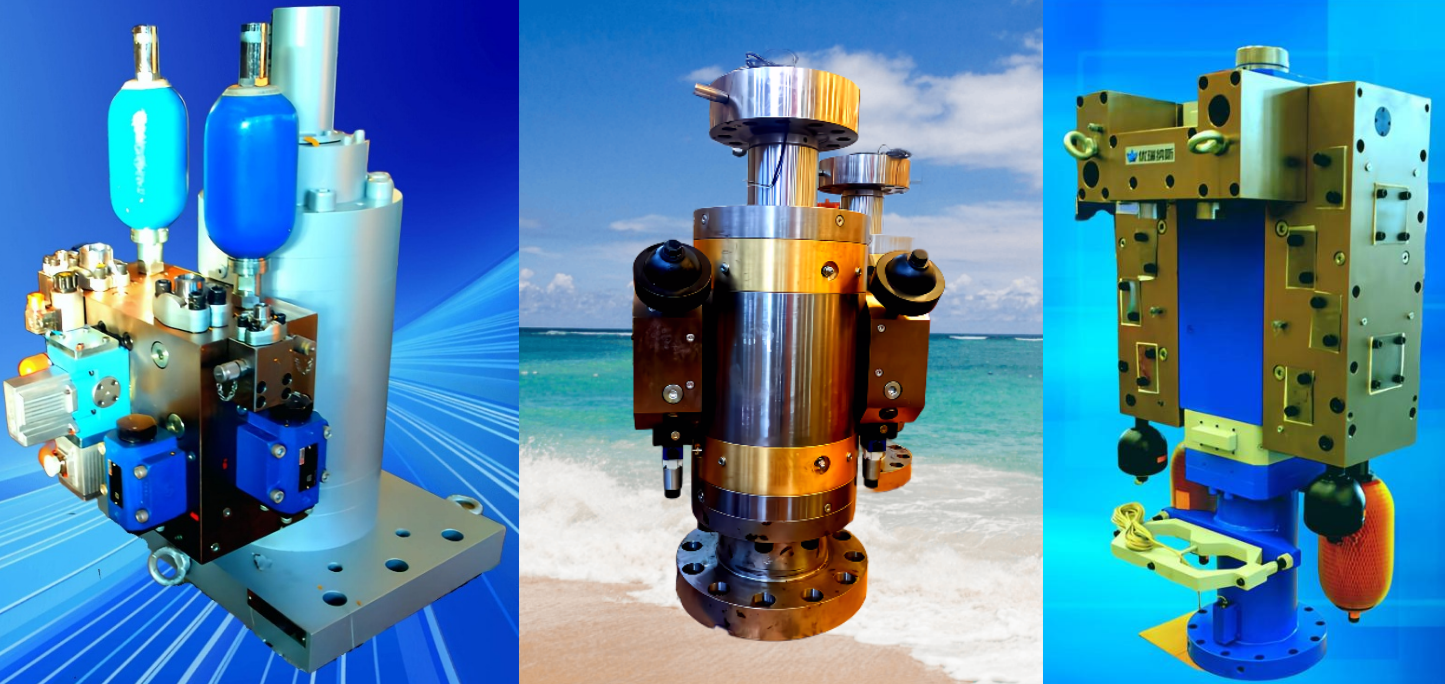

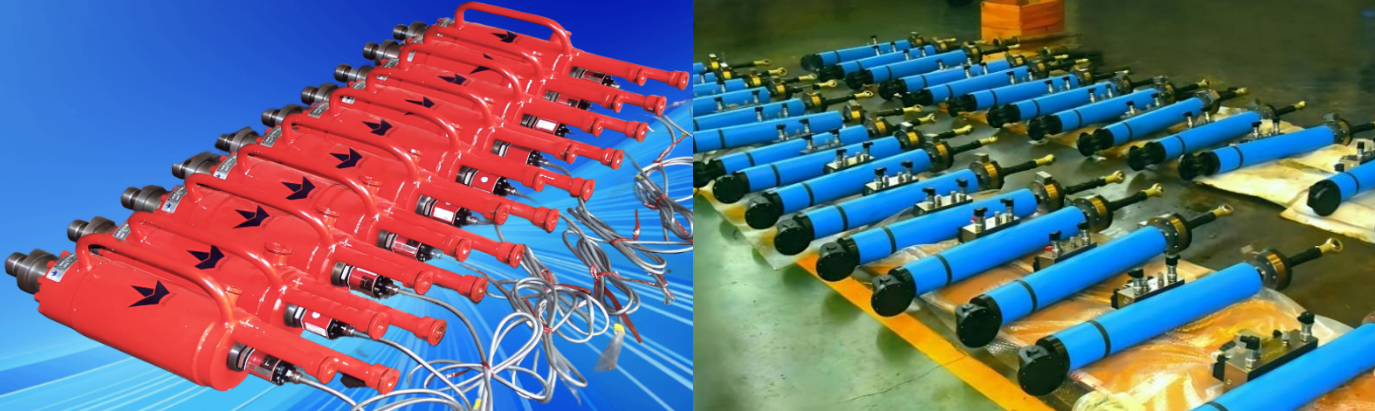

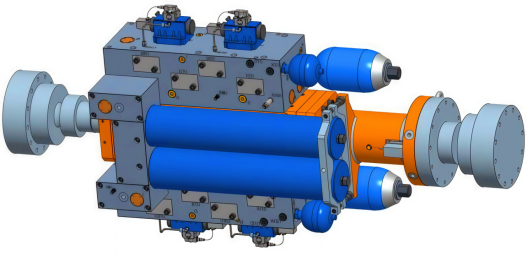

3.नाम: एम्बेडेड सेंटरिंग ट्रिपल-सिलेंडर कॉम्पोजिट सर्वो हाइड्रोलिक एक्चुएटर;

मॉडल: USYQ225/195-32+140/50-32HA+FK

कंपन सिलेंडर: बोर 225 मिमी; रॉड 195 मिमी; स्ट्रोक ±16 मिमी; कुशन स्ट्रोक 50 मिमी

कार्यशील दबाव 21 MPa; परीक्षण दबाव 32 MPa; कंपन आवृत्ति 200 Hz

एम्बेडेड सेंटरिंग सिलेंडर: बोर 140 मिमी; रॉड 50 मिमी; स्ट्रोक ±16 मिमी; कुशन स्ट्रोक 50 मिमी

कार्यशील दबाव 21 MPa; परीक्षण दबाव 32 MPa

संतुलन सिलेंडर: पिस्टन व्यास 220 मिमी; रॉड-साइड क्षेत्र 8149 mm²; एनुलर क्षेत्र 38013 mm²

4.नाम: रैक-एंड-पिनियन स्विंग सर्वो हाइड्रोलिक सिलेंडर; मॉडल: UBFKD40-90°

बोर: 40 मिमी; स्विंग कोण 90°; कंपन आवृत्ति 50 Hz; आयाम ±3°

बाह्य कोणीय विस्थापन सेंसर

कार्यशील दबाव: 14 MPa; परीक्षण दबाव: 21 MPa; अभिहित दबाव पर निर्गत टॉर्क 770 N·m

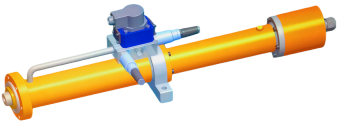

5.नाम: सर्वो हाइड्रोलिक सिलेंडर; मॉडल: UGDT40/28-200

बोर: 40 मिमी; रॉड: 28 मिमी; स्ट्रोक ±100 मिमी; कंपन आवृत्ति 200 हर्ट्ज़; आयाम ±1–10 मिमी

कार्यदाब: 16MPa; परीक्षण दबाव: 24 MPa;

अंतर्निर्मित विस्थापन सेंसर, सर्वो वाल्व स्थापित

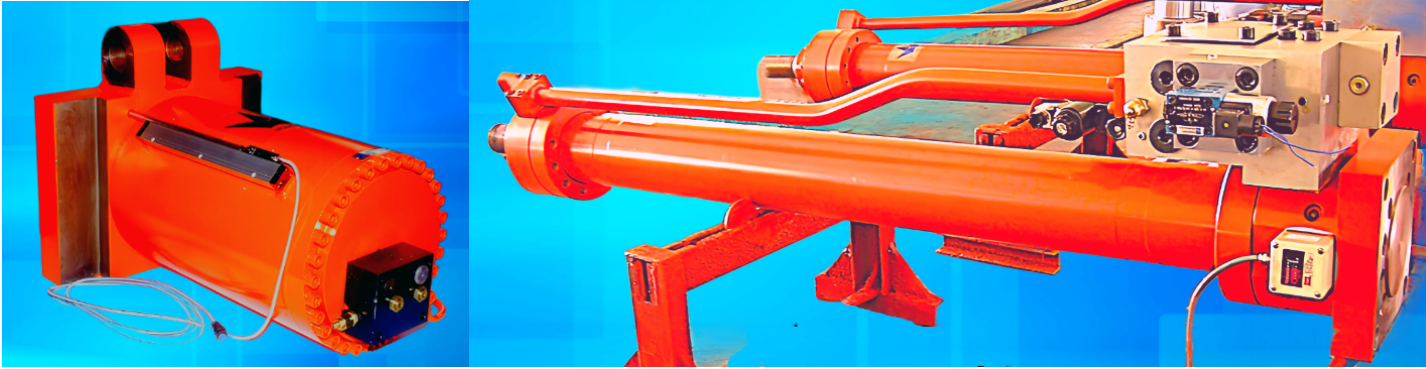

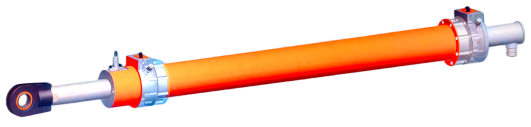

6.नाम: उच्च-तापमान सर्वो हाइड्रोलिक सिलेंडर; मॉडल: UYS100/70-1100

बोर: 100 मिमी; रॉड: 70 मिमी; स्ट्रोक 1100 मिमी

अंतर्निर्मित विस्थापन सेंसर; पिस्टन रॉड के सिरे पर मैग्नेटोस्ट्रिक्टिव विस्थापन सेंसर

कार्यदाब: 16 MPa; परीक्षण दबाव: 24 MPa

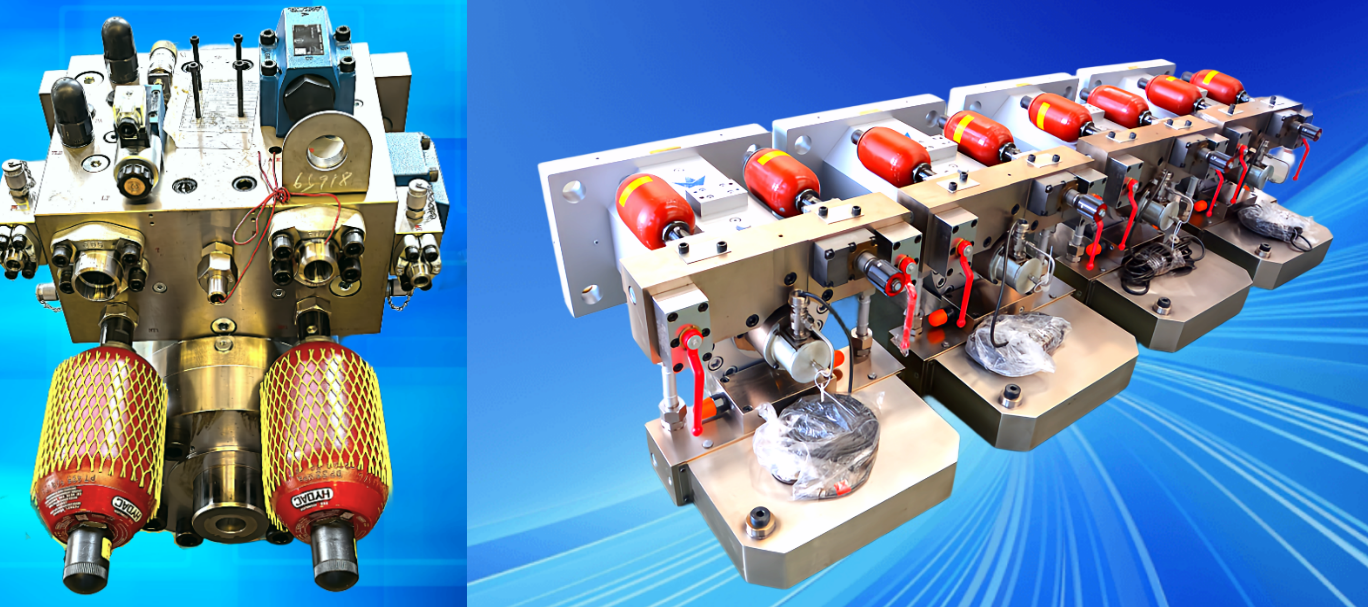

7.नाम: सामग्री थकान परीक्षण मशीन सर्वो हाइड्रोलिक सिलेंडर; मॉडल: UYSTD800+500/360-620

बोर: बड़ा सिलेंडर 800 मिमी; छोटा सिलेंडर 500 मिमी; रॉड 360 मिमी; स्ट्रोक ±305 मिमी

कार्यशील दबाव: 23 MPa; परीक्षण दबाव: 37.5 MPa; प्रारंभिक दबाव ≤ 0.1 MPa

अंतर्निर्मित विस्थापन सेंसर; कंपन आवृत्ति 1–10 हर्ट्ज़