Understanding Rotary Unions in Hydraulic Excavators

Core Components of a Rotary Union

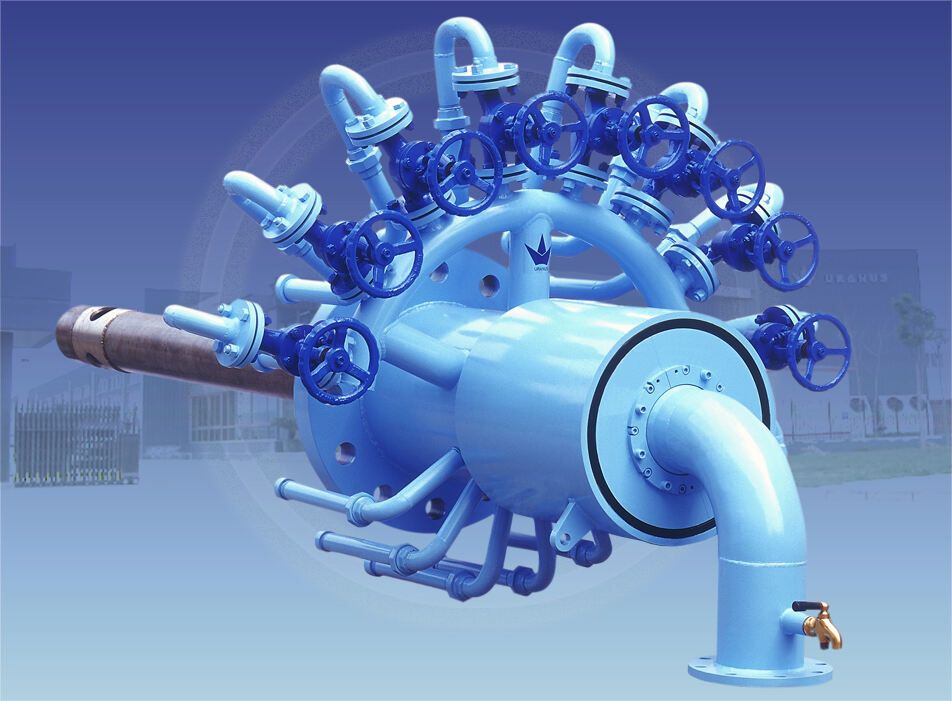

Rotary unions are essential components in hydraulic systems, serving as connectors that enable fluid transfer while allowing continuous rotation. These unions consist of various core components, including seals, bearings, and rotors, each contributing significantly to their performance. Seals are crucial for preventing leakage and ensuring efficient fluid transfer, while bearings facilitate smooth rotation, minimizing wear and tear on moving parts. Rotors are responsible for directing fluid flow through the rotary union, optimizing its efficiency. The materials used to manufacture rotary unions, such as stainless steel or brass, must exhibit corrosion resistance and durability to withstand harsh hydraulic environments.

Integration with Hydraulic Power Units

Rotary unions are integrated with hydraulic power units, playing a significant role in optimizing system efficiency. They facilitate fluid transfer between stationary and rotating parts by providing a seamless passage for hydraulic fluid, maintaining effective flow paths. This integration ensures proper fluid pressure and flow rate, which are vital for the optimal performance of hydraulic excavators. Proper alignment of rotary unions with hydraulic power units also reduces strain on components, preventing system failures and extending the service life of the machinery involved.

Role in 360-Degree Fluid Transfer

Rotary unions are instrumental in enabling 360-degree fluid transfer in hydraulic applications, allowing machinery to perform complex operations seamlessly. Their design ensures uninterrupted fluid delivery, facilitating machinery operations without the risk of leaks or fluid contamination. This capability is crucial for excavators, where fluid must circulate continuously for efficient functioning. Advanced rotary union designs contribute to efficiency improvements in excavators, making complex automotive tasks more manageable. These unions have demonstrated enhanced operational capabilities in various industrial settings, proving their value in hydraulic excavator applications.

Advantages of 360-Degree Sealing Technology

Leak Prevention in Hydraulic Cylinders

The introduction of 360-degree sealing technology marks a pivotal advancement in preventing leaks associated with hydraulic cylinders. Leaks are a prevalent issue in hydraulic systems, leading to inefficiencies and elevated maintenance costs. For instance, data shows that hydraulic leaks can account for up to 80% of system failures, compelling industries to seek more effective sealing solutions. Implementing 360-degree sealing technology considerably lowers leak rates, enhancing the performance, reliability, and lifespan of hydraulic systems. This reduction in leaks also translates to significant maintenance cost savings over time, underscoring its value in hydraulic operations.

Enhanced Durability for Heavy-Duty Applications

360-degree sealing technology enhances the durability of components operating in heavy-duty and harsh environments. Traditional seals often falter under intense operational pressures, but 360-degree seals provide a robust solution. They are particularly advantageous in industries like metallurgy, shipbuilding, and heavy machinery, where traditional seals frequently fail. According to industry experts, this technology surpasses conventional seals in durability and longevity, meeting stringent industry standards. This enhancement in durability ensures that machinery can withstand demanding conditions without frequent seal failures, which is crucial for operations where downtimes can lead to significant economic loss.

Reduced Friction in Hydraulic Press Systems

In hydraulic press systems, 360-degree sealing technology significantly reduces friction, offering a host of benefits. Reduced friction leads directly to better energy efficiency and faster operational speeds. Traditional seals, often plagued by higher friction levels, fail to deliver these efficiencies, resulting in higher energy consumption. Comparatively, systems using 360-degree seals consume less energy and operate more efficiently, thus driving down operational costs while increasing productivity. This advanced sealing technology not only optimizes energy consumption but also extends the life of the machinery, ultimately improving the return on investment for hydraulic press system operators.

Rotary Union Applications Across Industries

Metallurgy & Heavy Machinery

Rotary unions play a pivotal role in the metallurgy and heavy machinery sectors by addressing fluid management issues and ensuring smooth operational processes. They are extensively utilized in applications such as rolling mills, smelting processes, and other metal-forming operations where continuous fluid transfer is crucial. The challenges in these sectors often revolve around managing high temperatures and pressures, which can lead to equipment failure without proper handling. Rotary unions help mitigate these issues by providing a robust solution for transferring cooling agents and hydraulic power under such strenuous conditions. For instance, a case study in a steel manufacturing plant demonstrated that incorporating rotary unions led to a 15% improvement in operational efficiency, highlighting their impact in supporting complex metallurgy applications.

Marine Engineering Adaptations

In marine engineering, rotary unions are adapted to withstand the unique environmental challenges posed by high pressures, saltwater corrosion, and constant movement. These unions are designed with specialized seals and materials that ensure reliability and longevity in marine settings, where traditional components might fail. They are commonly used in applications like propeller systems, winches, and steering mechanisms, where reliable fluid transfer and protection against harsh elements are necessary. A successful marine project involving an advanced naval vessel showcased the effectiveness of rotary unions in maintaining optimal performance despite the harsh marine conditions, thus underscoring their critical role in enhancing engineering capabilities at sea.

Aerospace Precision Requirements

The aerospace industry demands unparalleled precision and reliability, and rotary unions meet these stringent standards by incorporating advanced materials and technologies. These unions are crafted from high-grade materials that possess excellent heat and fluid resistance, ensuring they can withstand the extreme conditions experienced during flight. The design and manufacturing of aerospace rotary unions adhere to authoritative standards, such as those established by the Federal Aviation Administration (FAA), guaranteeing compliance with industry regulations. Their usage is critical in systems like fuel transfer and landing gear operations, where precise fluid management is non-negotiable. By adhering to these standards, aerospace rotary unions effectively support the intricate and precise mechanisms essential to modern aviation.

Optimizing Excavator Performance

Synchronization with Hydraulic Lifts

Rotary unions play a crucial role in enhancing the synchronization of hydraulic lifts within excavators. This synchronization is vital for maintaining balance and force distribution, leading to improved safety and operational efficiency. Imagine an operation where multiple hydraulics must work in harmony; rotary unions ensure that the flow of hydraulic fluids is consistent and controlled. Studies have shown that excavators with synchronized operations achieve higher productivity and lower downtime. By ensuring that hydraulic lifts operate in concert, rotary unions not only boost performance but also significantly reduce wear and tear on equipment.

Precision Control for Hydraulic Jack Systems

The role of rotary unions extends to providing precision control in hydraulic jack systems, which is vital during excavation. This precision control allows for smooth and nuanced movements, essential when operating in challenging terrains. For instance, in excavation projects where minute adjustments can significantly affect stability, rotary unions enhance the operator's ability to manage these tasks efficiently. Data shows a marked improvement in task execution with the integration of rotary unions into jack systems, emphasizing the importance of precision and reliability. By ensuring stable pressure and flow, rotary unions minimize risks and maximize control.

Case Study: Long-Term Efficiency Gains

A detailed case study reveals substantial long-term efficiency gains in excavators equipped with 360-degree sealing technology through rotary unions. Data from before and after the implementation shows a marked increase in productivity and reduced operational costs. The 360-degree sealing ensures minimal fluid leakage, translating into consistent performance and lower maintenance requirements. Over time, this leads to significant cost savings as there is less need for repairs and parts replacement, proving rotary unions to be a worthwhile investment for excavators looking to enhance productivity and longevity.