Reel Expansion and Contraction Cylinders

Coiler Expansion Hydraulic Cylinder

Product Overview

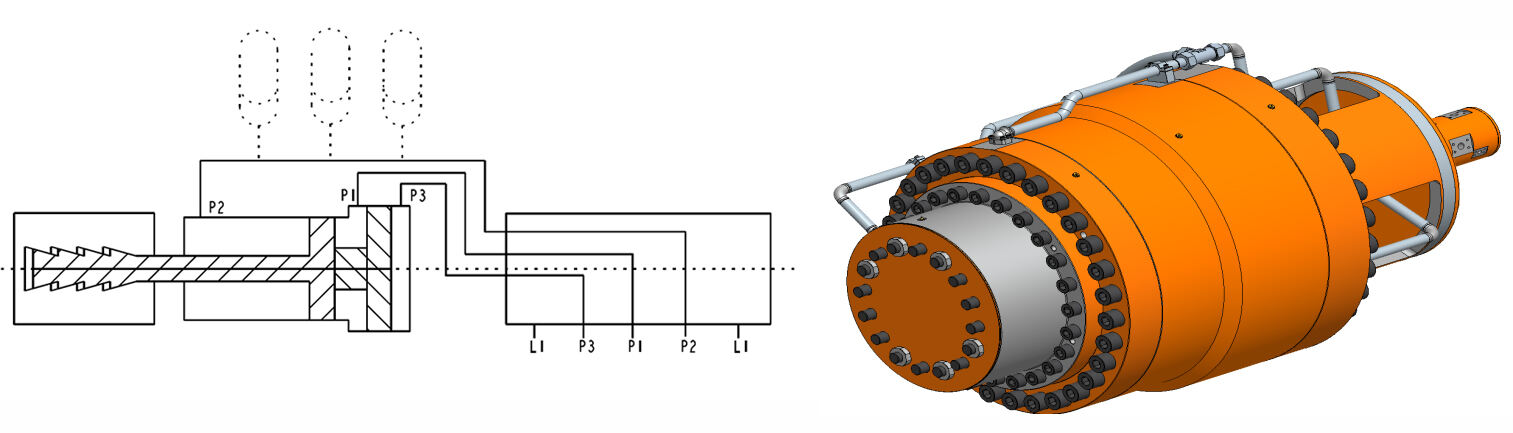

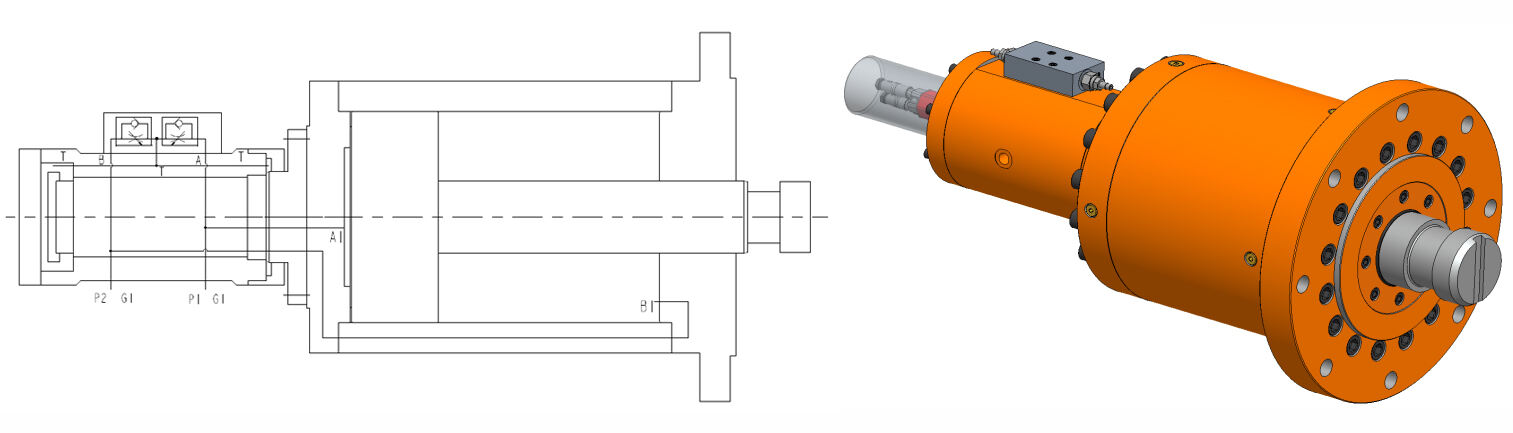

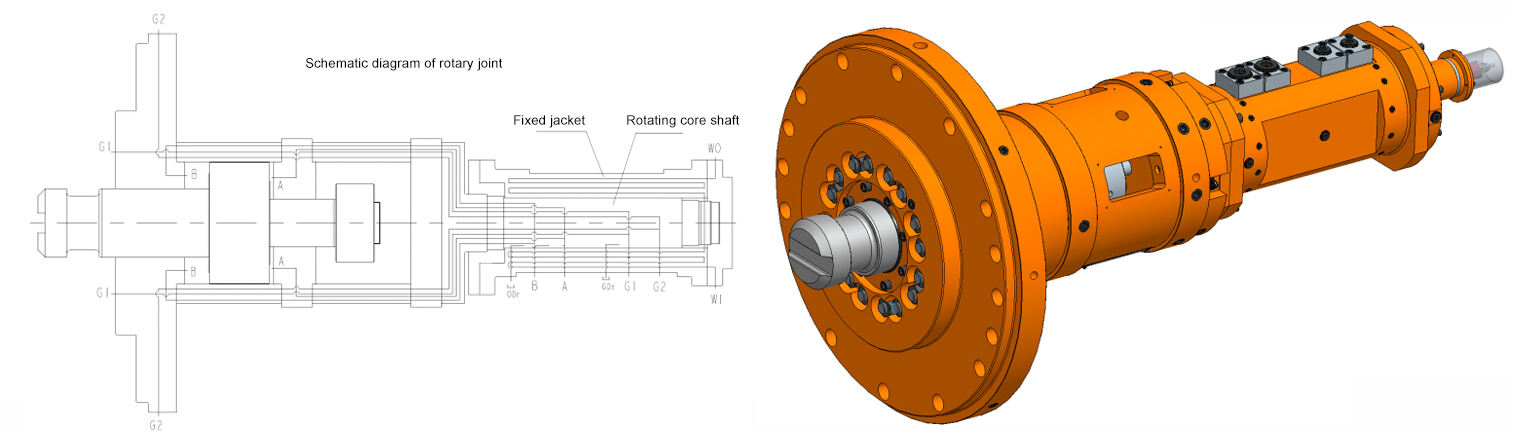

The coiler expansion cylinder consists of a double-acting hydraulic cylinder combined with a rotary joint. Its main function is to expand and contract the drum diameter of coilers or uncoilers by extending and retracting the cylinder during rotation.

For precise stroke control, a displacement sensor can be installed, with an optional pressure sensor for accurate monitoring and control of push-pull actions. Two exhaust/pressure test ports are located on the top of the rotary joint, while each side has four inlet/outlet ports—two in use and the others sealed. The leakage port at the bottom must be connected to the return line to ensure smooth oil return and prevent external leakage caused by back pressure exceeding 0.5 bar.

A torque arm hole is provided beneath the rotary joint to fix an anti-rotation bar (floating positioning to avoid axial load). The flange surface must be perpendicular to the rotation axis, ensuring radial run-out ≤1 mm. Oil and leakage pipelines should be firmly fixed to avoid radial or axial forces on the rotary joint. For high-temperature hot-rolling coilers requiring cooling water, expansion cylinders with an integrated water rotary joint are available.

Key Features

Two exhaust pressure measuring joints are installed above the rotary joint, allowing for convenient gas venting from both chambers of the telescopic cylinder and real-time detection of oil pressure in these chambers. For easy use, four oil inlet and outlet ports are positioned on both sides of the rotary joint's horizontal axis. You can select any two ports for use, while the remaining two can be sealed with sealing screws.

Uranus expansion and contraction cylinders are equipped with high-quality reciprocating and rotary seals. Precision bearings are installed in the rotary joint, ensuring reliability and long service life. In the past 20 years, we have developed and produced over a thousand expansion and contraction cylinders for global users. These cylinders are widely used in both cold and hot rolling, plate and strip reeling machines,as well as many engineering machinery, injection molding machinery and chemical equipment.

Uranus has produced expansion and contraction cylinders with diameters ranging from a minimum of 100mm to a maximum diameter of 900mm. In addition, they have a maximum operating pressure of 25MPa. These cylinders can be custom-designed and manufactured to meet specific customer needs or can be produced based on drawings provided by customers.

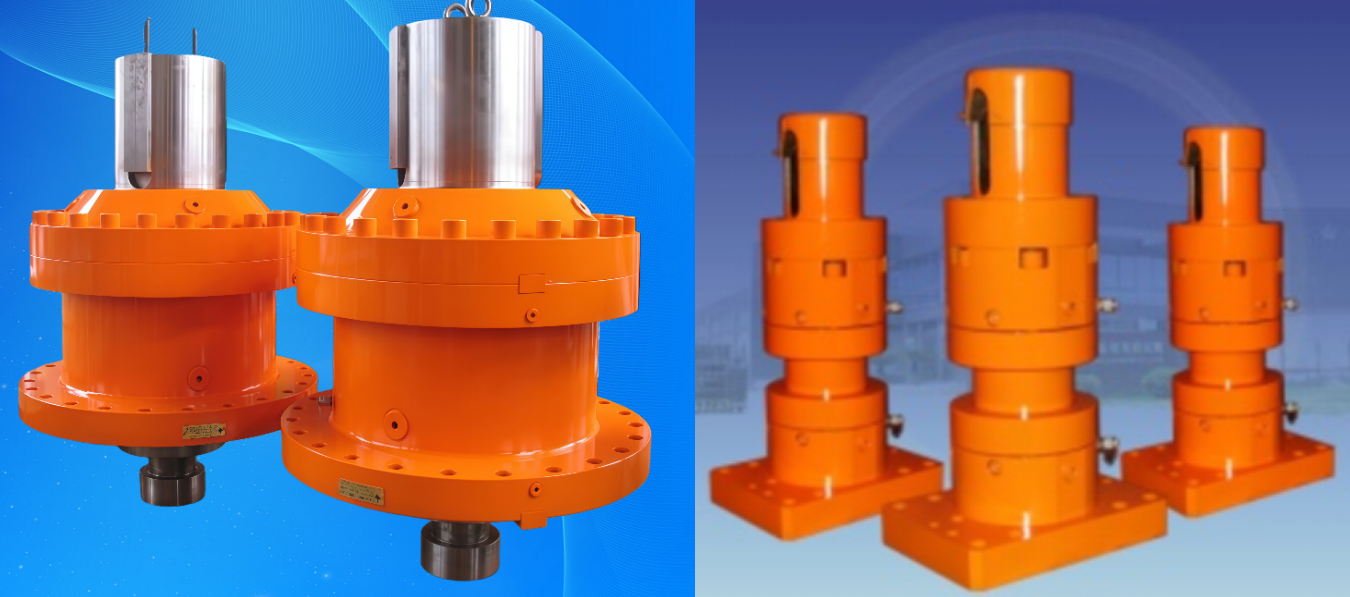

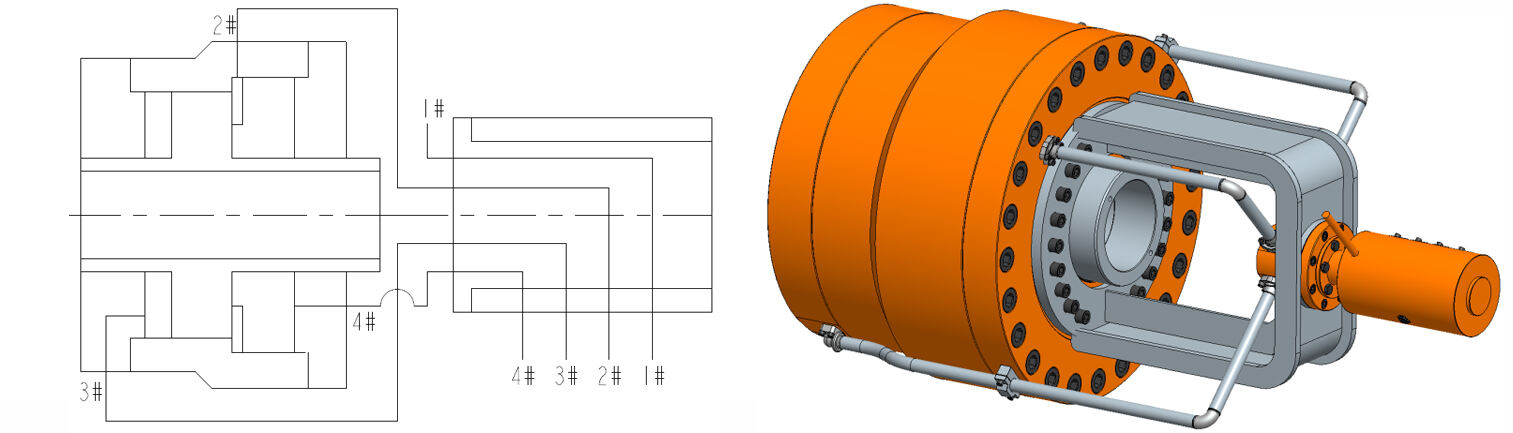

Below are examples of several types of expansion and contraction cylinders:

1.Expansion and contraction cylinder (two cylinders in series) Large cylinder diameter: 900; rod diameter: 360; stroke: 17;

Small cylinder diameter: 850; rod diameter: 360; stroke: 77

Built-in displacement sensor

Operating pressure 10MPa; test pressure: 15MPa

Rated speed: 450r/min

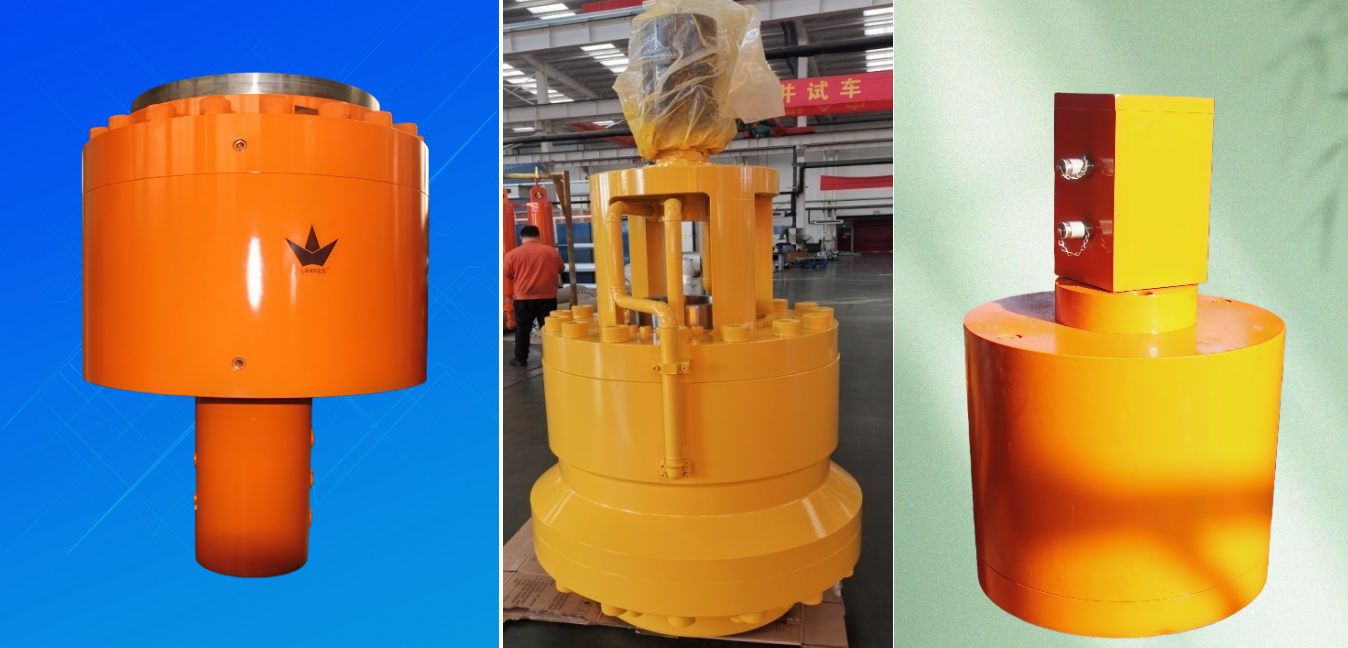

2.Reel-Expansion-and-Contraction-Cylinders14.jpg

Reeler and roller expansion and contraction cylinder diameter: 250; rod diameter: 110; stroke: 113.5; buffer stroke: 30;

Built-in displacement sensor

Operating pressure 14MPa; test pressure: 21MPa

Rated speed: 650r/min

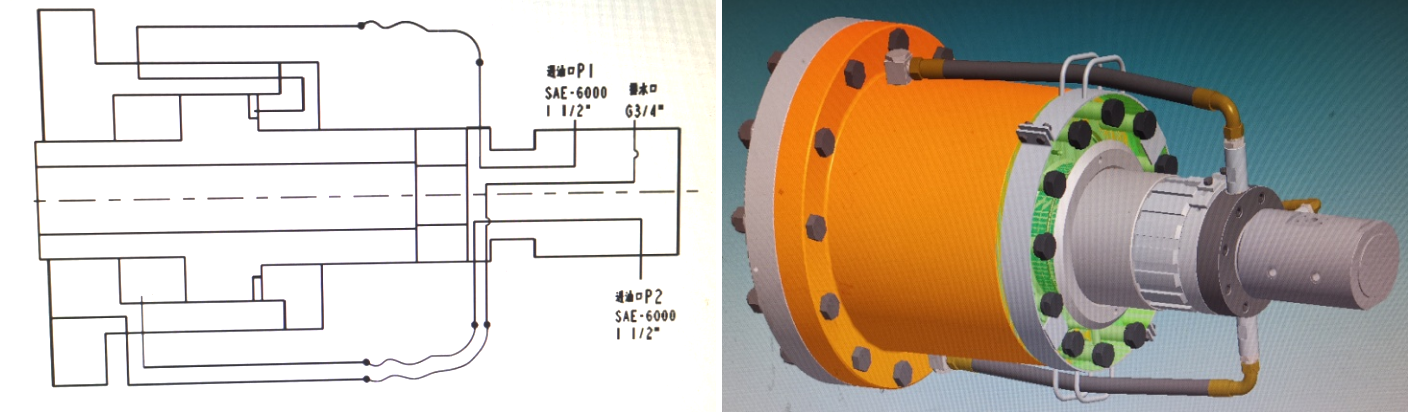

3.Expansion and contraction cylinder (two cylinders in series) Large cylinder diameter: 760; rod diameter: 315; stroke: 20;

Small cylinder diameter: 680; rod diameter: 315; stroke: 75

Built-in displacement sensor

Operating pressure 12MPa; test pressure: 21MPa

Rated speed: 450r/min

4.Rotary telescopic cylinder diameter: 320; rod diameter: 180; stroke: 74;

Built-in displacement sensor Rotating joint jacket Cooling water jacket

Operating pressure 21MPa; test pressure: 25MPa;

Rated speed: 3800r/min

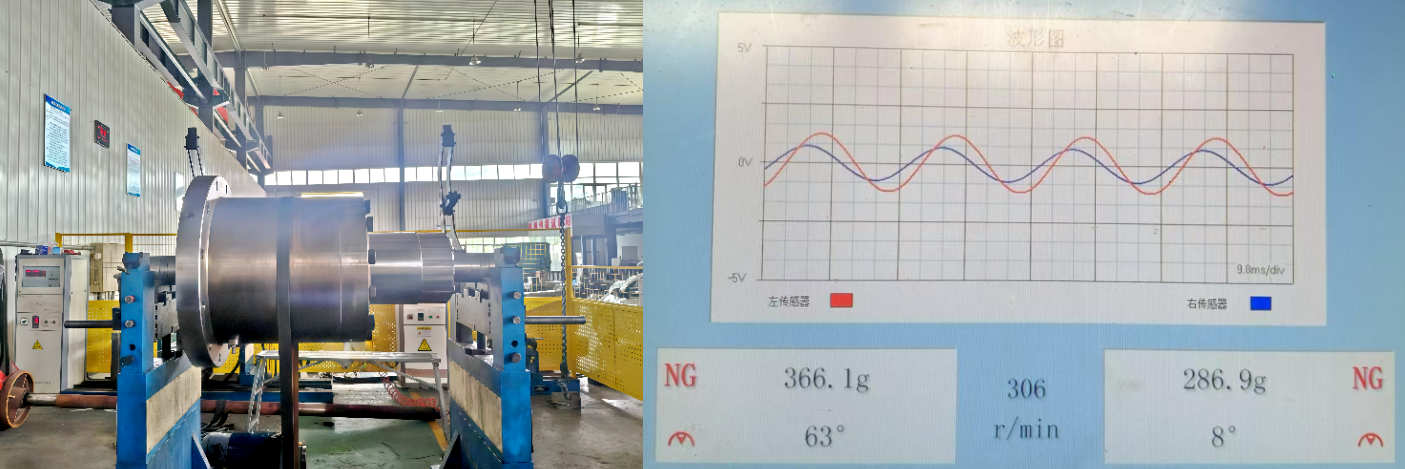

Dynamic Balance Test Dynamic Balancing Waveform