High-Frequency Response Hydrostatic Servo Hydraulic Cylinder

Low-Friction Sealed High-Frequency Vibration Servo Hydraulic Cylinder

High-Frequency Response Hydrostatic Servo Hydraulic Cylinder

Revolutionizing Precision Motion with Hydrostatic Technology

Background

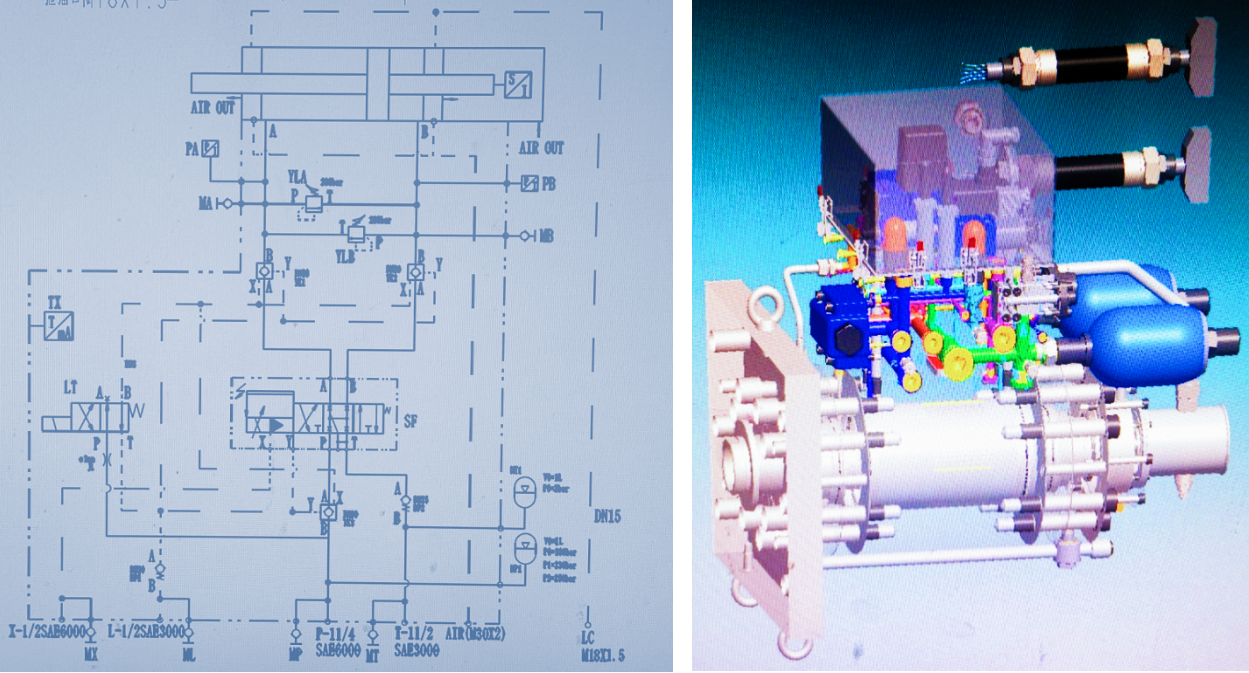

For over 30 years, Uranus has specialized in high-performance hydraulic cylinders. In 2013, we developed China’s first 350 Hz high-frequency hydrostatic servo cylinder, applied in a 250 g geotechnical centrifuge shaker—filling a domestic gap, reaching advanced international levels, and winning a National Science & Technology Award.

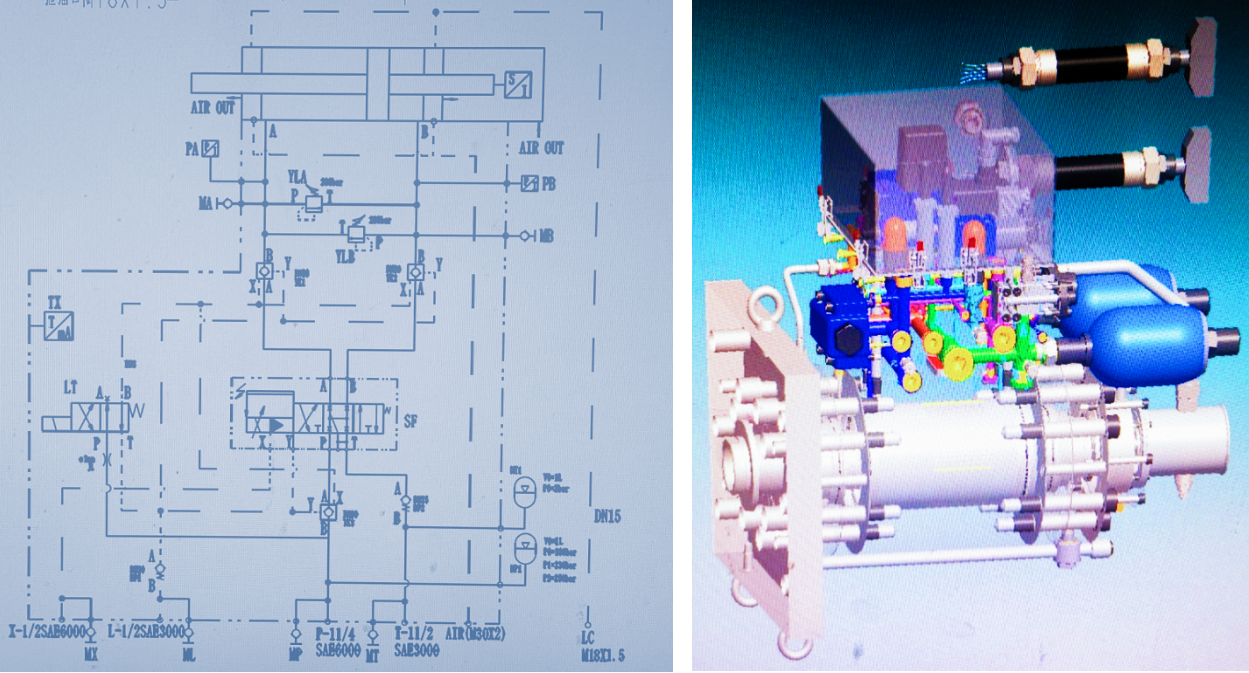

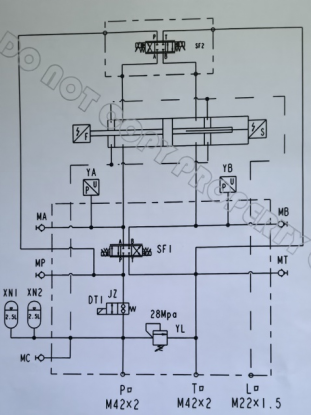

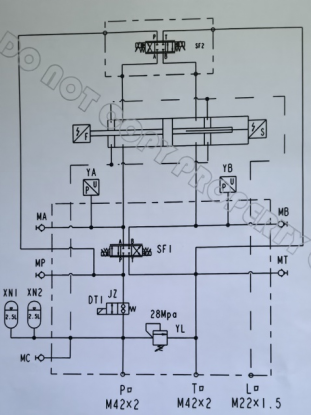

Principle & Advantages

● Hydrostatic non-contact support: A high-stiffness oil film between piston rod and guide bushing eliminates Coulomb friction, achieving near “zero-friction” motion.

● Smart closed-loop control: Servo valve bandwidth 100 Hz; built-in/external high-resolution displacement sensors ensure precise synchronization with high-frequency commands.

● Outstanding frequency response: −3 dB amplitude characteristic covers 50 Hz to several hundred Hz, capable of accurately reproducing complex non-sinusoidal waveforms.

Key Performance

● Micron-level precision and ultra-smooth low-speed motion

● High oil-film stiffness ensures strong anti-disturbance and excellent stability

● Withstands high radial/axial loads under harsh conditions

Applications

Successfully applied in:

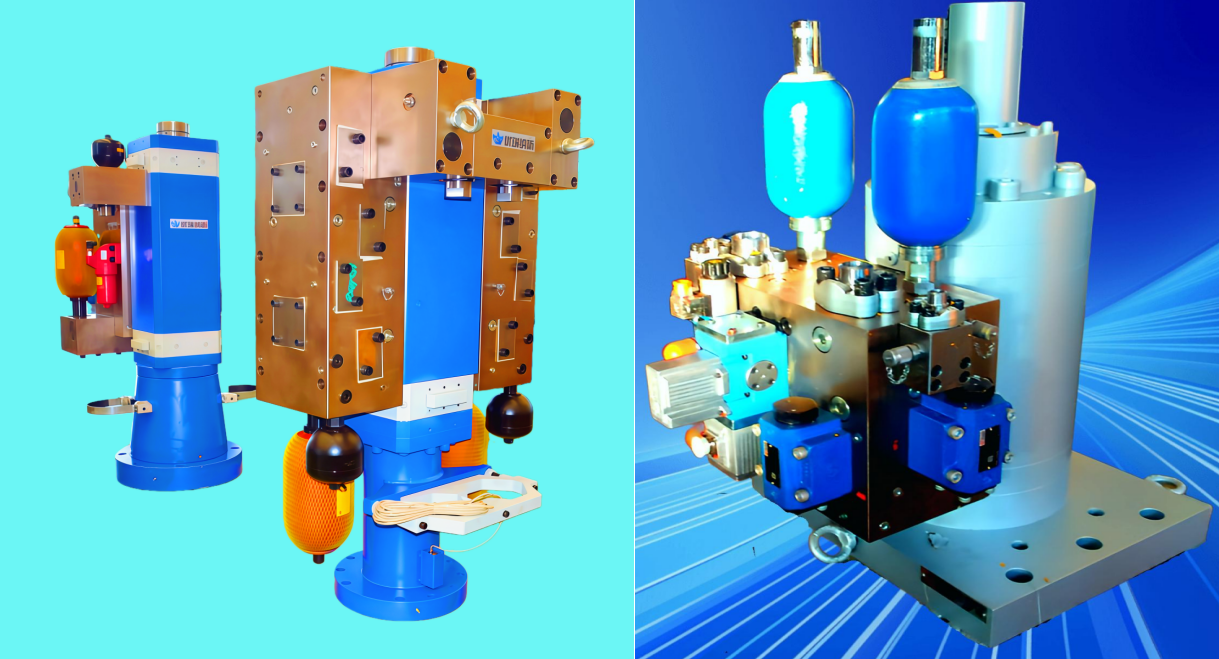

● Aerospace vibration simulation

● Mold oscillation in steel continuous casting

● Material fatigue testing machines

● Automotive road impact and tire simulation platforms

● Ultra-gravity centrifuge vibration rigs

● High-frequency servo pressing and cold forging equipment

Customization & Cooperation

Non-standard customization and OEM are supported, delivering tailored solutions for advanced equipment.

Representative Models & Specifications

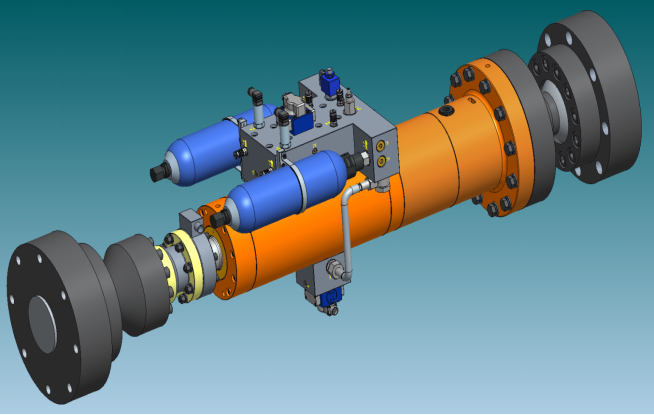

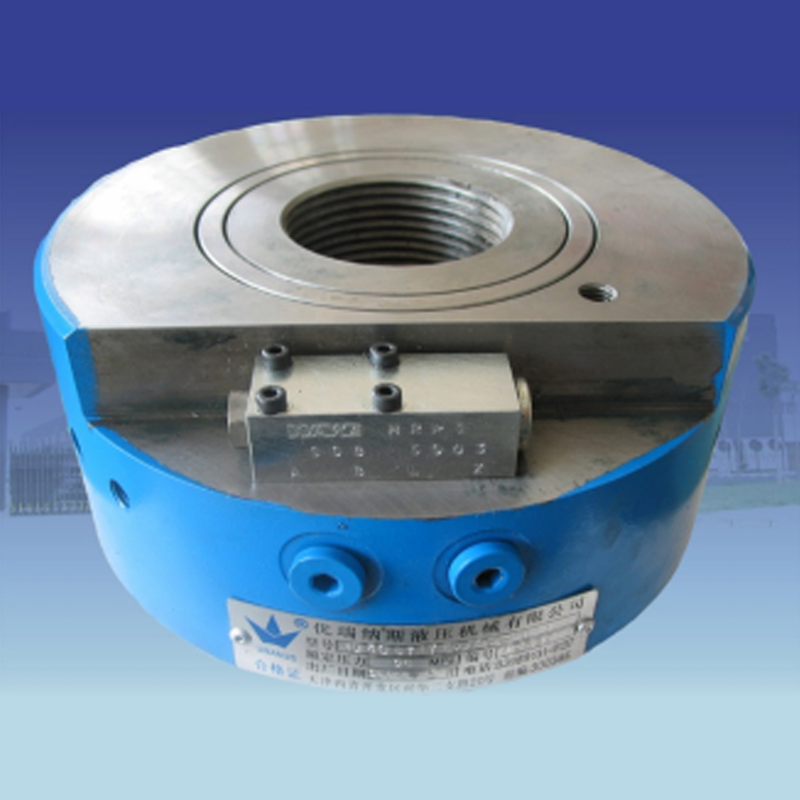

1、USY1302JD220/105-40H

Bore 220 mm; Rod 105 mm; Stroke ±20 mm

Working pressure 21 MPa; Test pressure 32 MPa; Case drain <0.02 MPa

Medium: Hydraulic oil; Temp −10℃~+80℃

Start pressure <0.1 MPa; Vibration 5–350 Hz

External displacement sensor

Application: 250 g centrifuge

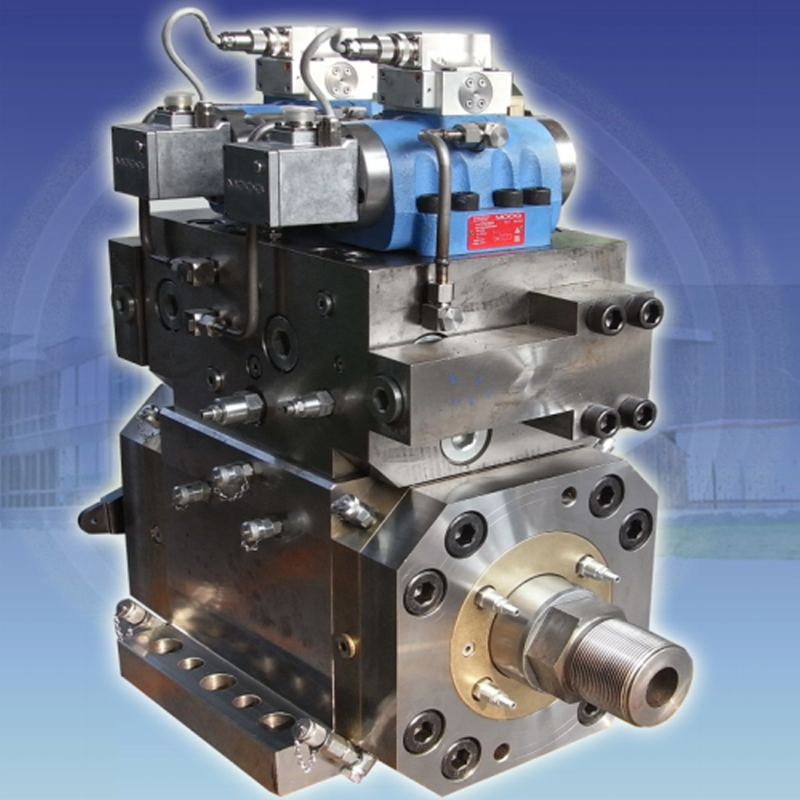

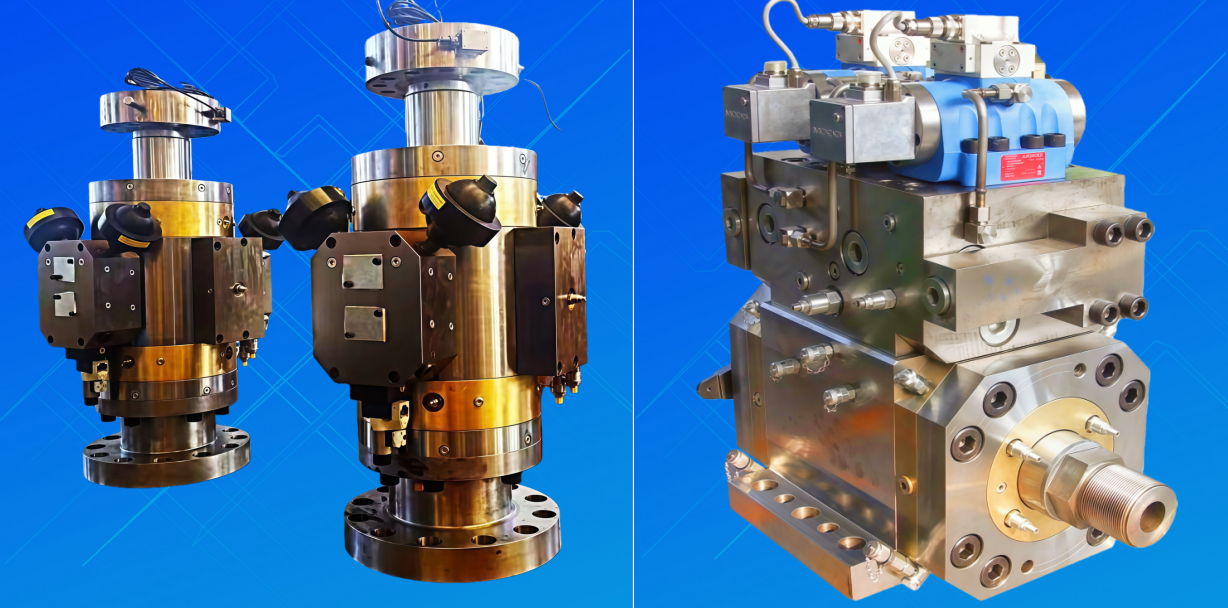

2、USY2202T230/160-120HS

Bore 220 mm; Rod 105 mm; Stroke ±20 mm

Working pressure 21 MPa; Test pressure 32 MPa

Medium: Hydraulic oil; Temp −10℃~+80℃

External leakage <7 L/min; Start <0.1 MPa; Vibration 5–350 Hz

Built-in displacement sensor

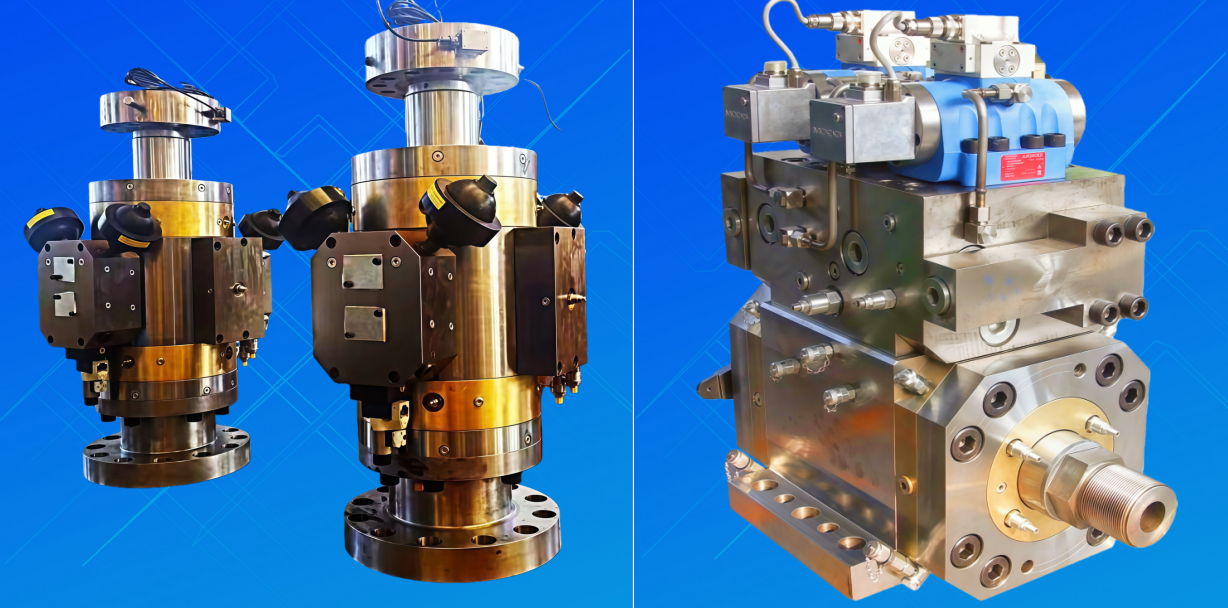

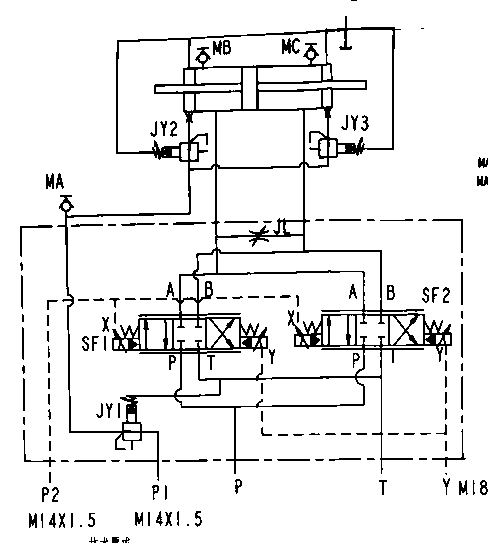

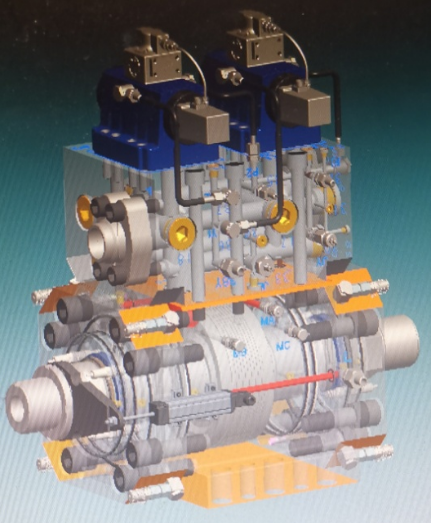

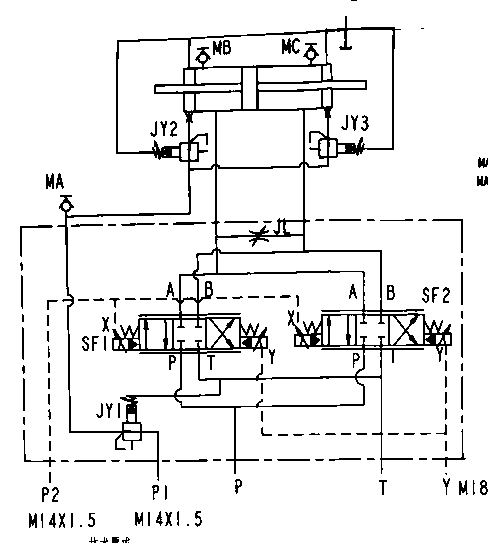

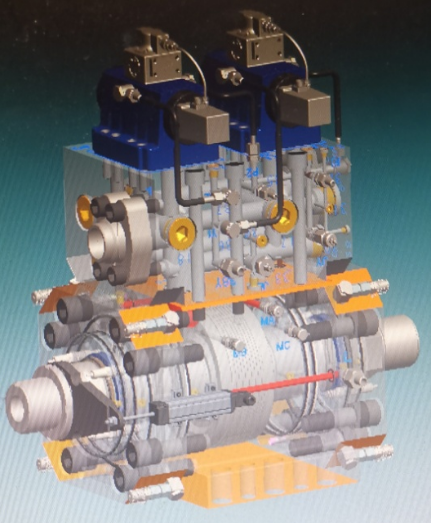

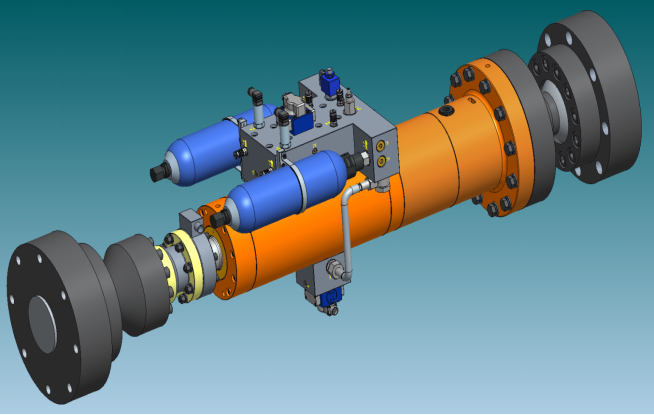

3、FLZJ-B + USY2210T110/80-110HS (Tire Load Simulator Actuator)

Bore 110 mm; Rod 80 mm; Stroke ±55 mm (Cushion 15×2)

Working pressure 28 MPa; Test pressure 35 MPa; Hydrostatic bearing 28 MPa

External leakage <10 L/min; Start <0.1 MPa

Built-in displacement sensor

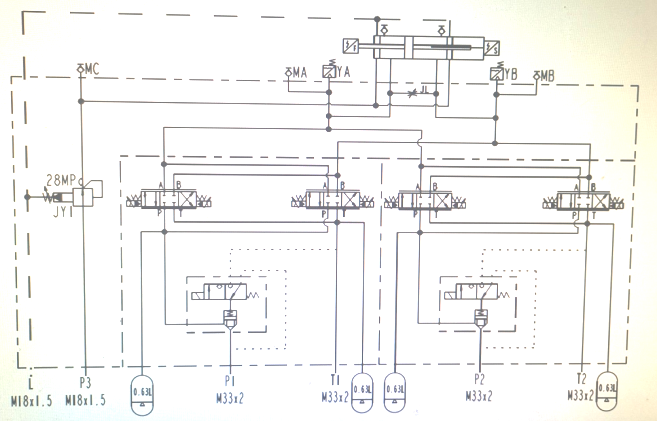

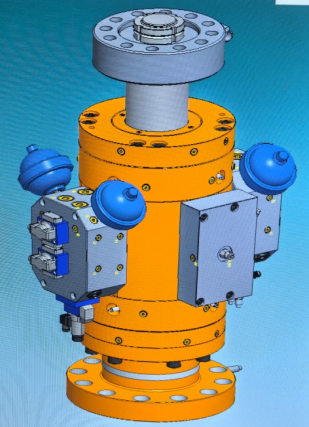

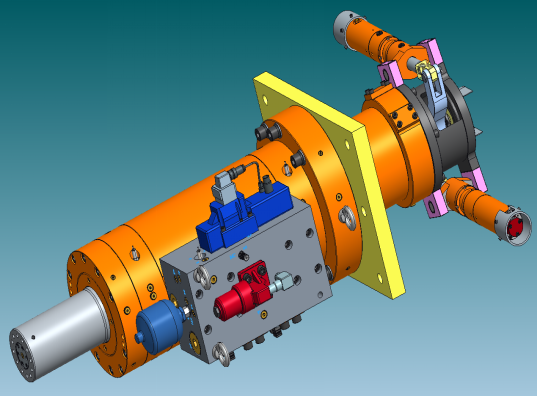

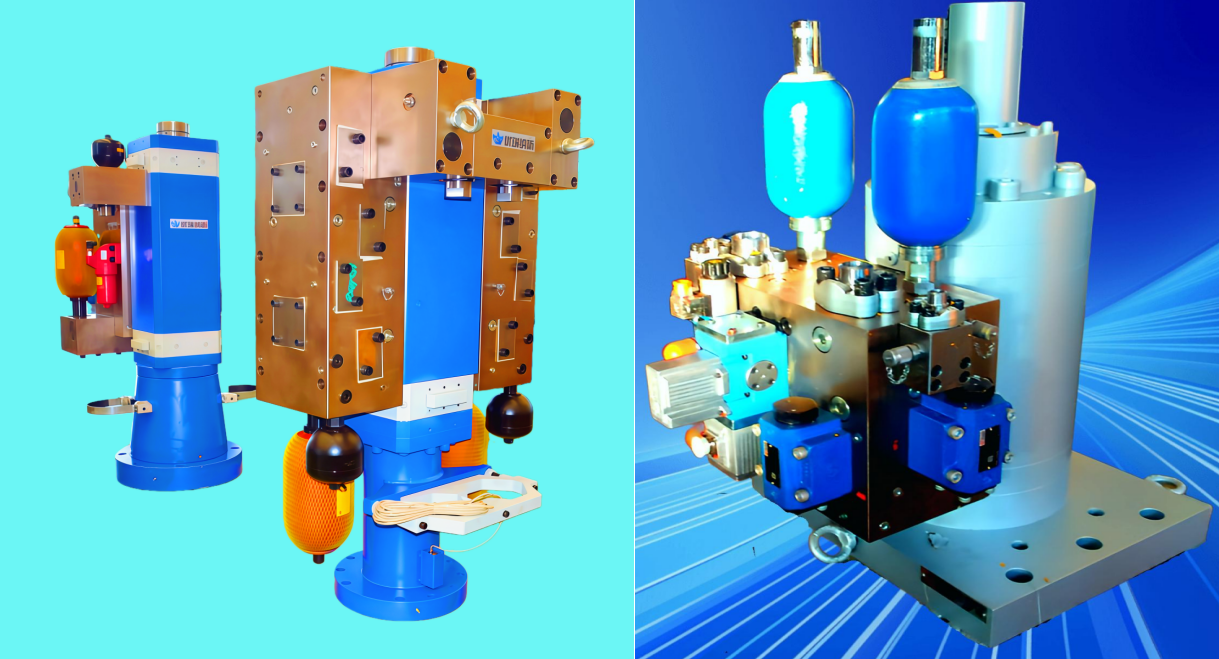

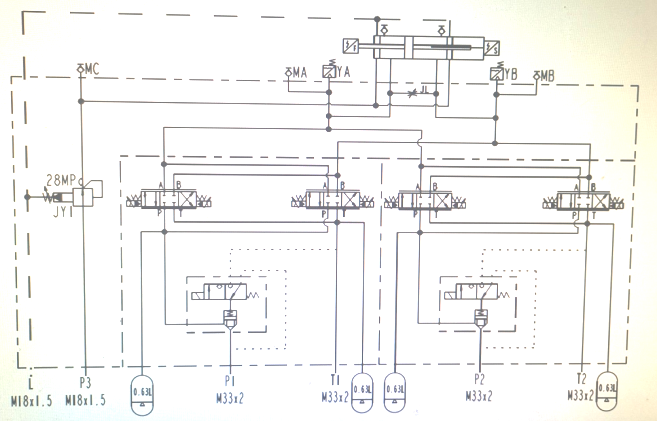

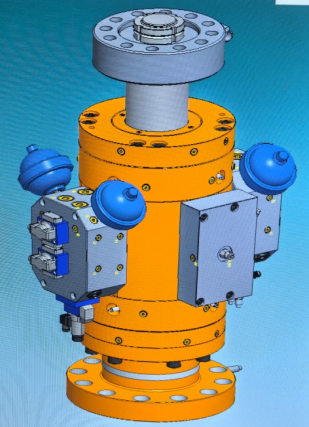

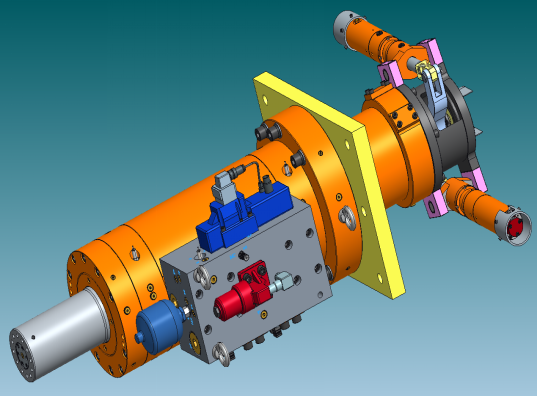

4. WZTJ + 4×USY2211Q190/160-150HS (Rotary High-Frequency Oscillation Cylinder)

Bore 190 mm; Rod 160 mm; Stroke 180 mm (Cushion 15×2)

Working pressure 28 MPa; Test pressure 35 MPa; Hydrostatic bearing 28 MPa

External leakage <10 L/min; Start <0.1 MPa

Built-in displacement sensor

5. WZTJ + 4×USY2211Q190/160-150HS (Rotary High-Frequency Oscillation Cylinder)

Bore 190 mm; Rod 160 mm; Stroke 180 mm (Cushion 15×2)

Working pressure 28 MPa; Test pressure 35 MPa; Hydrostatic bearing 28 MPa

External leakage <10 L/min; Start <0.1 MPa

Built-in displacement sensor