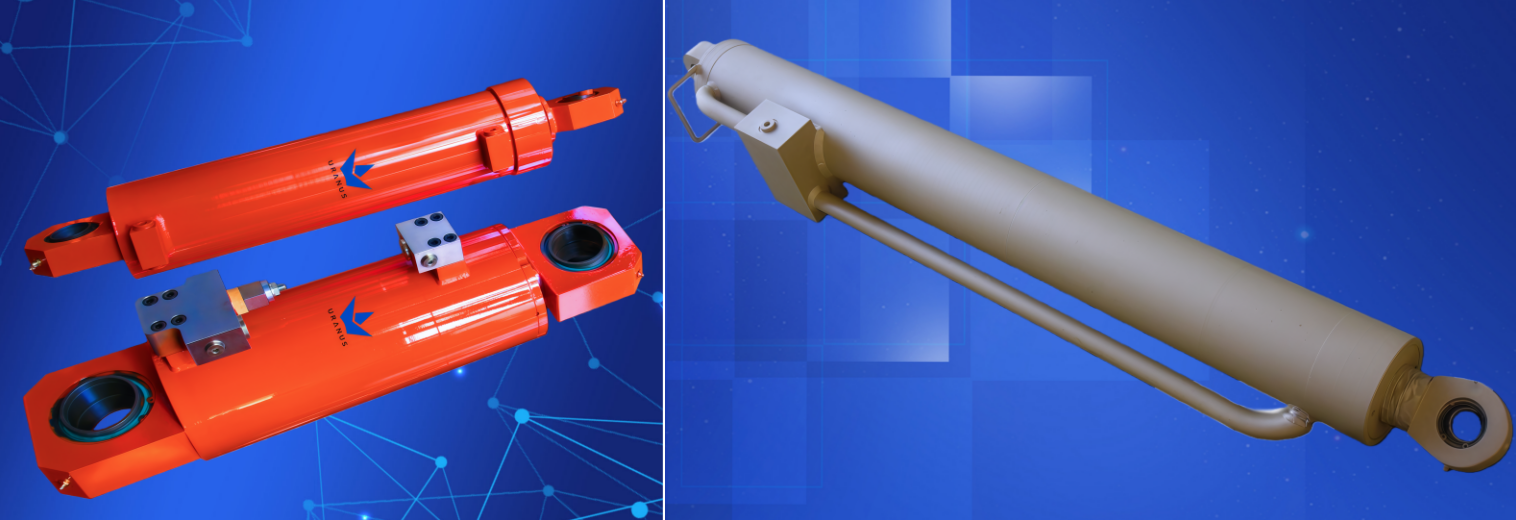

Photos of Construction Machinery Hydraulic Cylinder

UG Series Medium & High Pressure Hydraulic Cylinders

A Standardized Hydraulic Cylinder Platform Based on Decades of Custom Engineering Experience

Product Overview

The UG Series medium and high-pressure hydraulic cylinders are independently developed by Uranus Hydraulic based on decades of extensive experience in large-scale custom hydraulic cylinder manufacturing.

Designed on a standardized structural platform while retaining high modularity and configuration flexibility, the UG Series is suitable for construction machinery, industrial equipment, and heavy-duty applications. This series successfully integrates custom engineering capability with standardized industrial production, delivering stable performance, high reliability, and long service life.

Key Specifications & Configurations

Functional Types

Mounting Styles

・Front clevis mount

・Mid clevis mount

・Front flange mount

・Rear flange mount

・Foot mount

Rod End Connections

・Threaded rod end

・Self-lubricating bushing eye

・Spherical bearing eye

Pressure Ratings & Dimensions

・Pressure rating: 16 MPa / 21 MPa

・Bore diameter: φ40 – φ250 mm (15 sizes)

・Rod diameter: φ20 – φ180 mm (23 sizes)

・Maximum stroke: up to 10 m (subject to rod stability conditions)

Manufacturing Capability

Key components of the UG Series hydraulic cylinders—including piston rods, cylinder tubes, pistons, cylinder heads, and end caps—are manufactured using precision CNC machining centers and controlled under strict quality management procedures.

All cylinders are equipped with low-friction, high wear-resistant premium sealing systems, ensuring stable operation under high load, impact, and demanding working conditions.

Quality Control & Testing

Each UG Series hydraulic cylinder undergoes comprehensive performance testing prior to delivery, focusing on:

・Zero external leakage

・High mechanical efficiency

・Excellent resistance to shock and vibration

・Long service life

All product drawings, inspection records, and test reports are archived for more than 10 years, ensuring full traceability and quality verification.

Lifetime Quality Commitment

For any quality issues caused by design or manufacturing defects, Uranus Hydraulic provides lifetime free repair or replacement, offering long-term reliability and confidence to customers.

About Uranus Hydraulic

Founded in 1995, Uranus Hydraulic is a technology-driven manufacturer specializing in high-end hydraulic transmission products and mechatronic intelligent equipment integrating mechanics, hydraulics, optics, and electronics.

The company has archived over 50,000 sets of custom product drawings, holds 100+ national invention and utility model patents, and operates with 3D parametric design software, PDM product lifecycle management systems, and continuously optimized ERP systems.

Uranus Hydraulic is certified to ISO 9001, ISO 14001, and ISO 45001, and its products are widely trusted by customers worldwide for their technical sophistication and consistent quality.

Related Product Series

・UY Series Heavy-Duty & Metallurgy Hydraulic Cylinders (25 MPa)

・US Series Servo Cylinders with Integrated Magnetostrictive Sensors

・UB Series Rack & Pinion Rotary Hydraulic Cylinders

・UX Series High-Pressure Multi-Passage Rotary Joints

・UP Series Hydraulic Power Units

・UF Series Synchronous Distributor Hydraulic Cylinder

・UE Electro-hydraulic cylinders

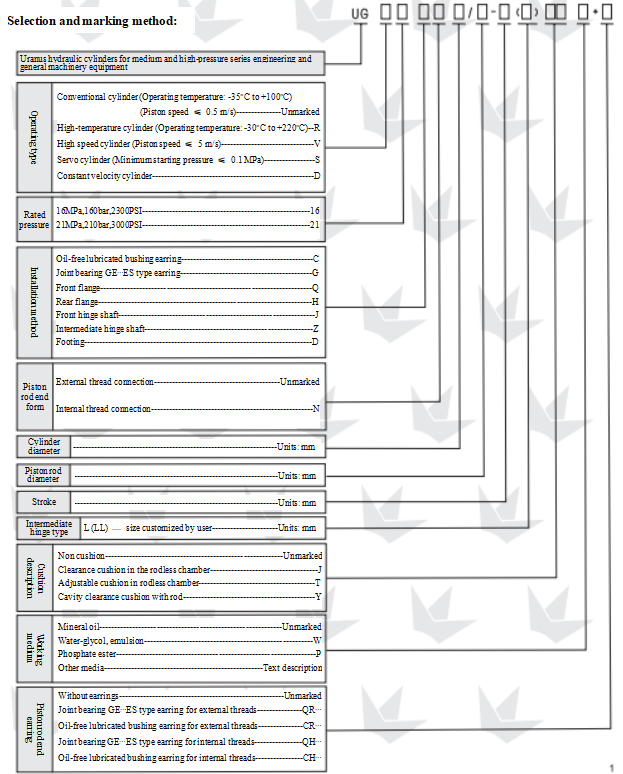

UG Medium and High-Pressure Series Engineering and General Machinery Equipment Hydraulic Cylinders

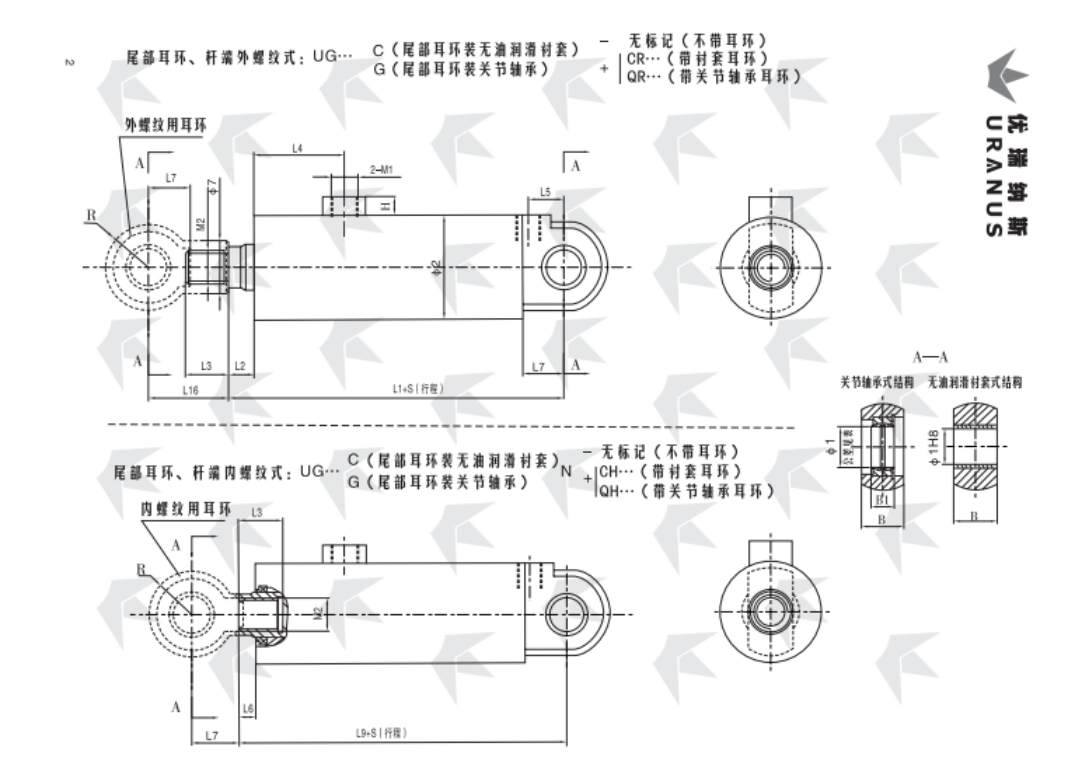

UG…C…oil-free lubricated bushing earring type, UG…G…joint bearing (GE..ES type) earring type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L9 |

L16 |

R |

B |

B1 |

H |

M |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

25 |

200 |

16 |

25 |

70 |

59 |

30 |

10 |

30 |

190 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

205 |

18 |

30 |

58 |

35 |

40 |

195 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||

63 |

32 |

83 |

35 |

245 |

20 |

35 |

73 |

76 |

40 |

15 |

235 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

42 |

260 |

45 |

75 |

45 |

18 |

55 |

255 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

110 |

M33×2 |

90-1 |

||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||

100 |

50 |

50 |

127 |

52 |

300 |

50 |

89 |

85 |

55 |

70 |

295 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||

110 |

56 |

140 |

60 |

305 |

55 |

90 |

90 |

300 |

135 |

M42×2 |

110-1 |

||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||

125 |

63 |

152 |

68 |

315 |

60 |

104 |

87 |

310 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

345 |

65 |

114 |

105 |

65 |

80 |

340 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||

150 |

75 |

180 |

76 |

350 |

70 |

119 |

110 |

345 |

157 |

M56×2 |

150-1 |

||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||

160 |

80 |

194 |

80 |

355 |

75 |

124 |

115 |

350 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

410 |

25 |

85 |

129 |

122 |

75 |

22 |

90 |

400 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

430 |

95 |

141 |

127 |

85 |

100 |

420 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

110 |

465 |

105 |

146 |

143 |

90 |

110 |

455 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||

250 |

125 |

100 |

299 |

120 |

485 |

115 |

155 |

100 |

120 |

475 |

245 |

110 |

70 |

M95×3 |

250-1 |

||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||

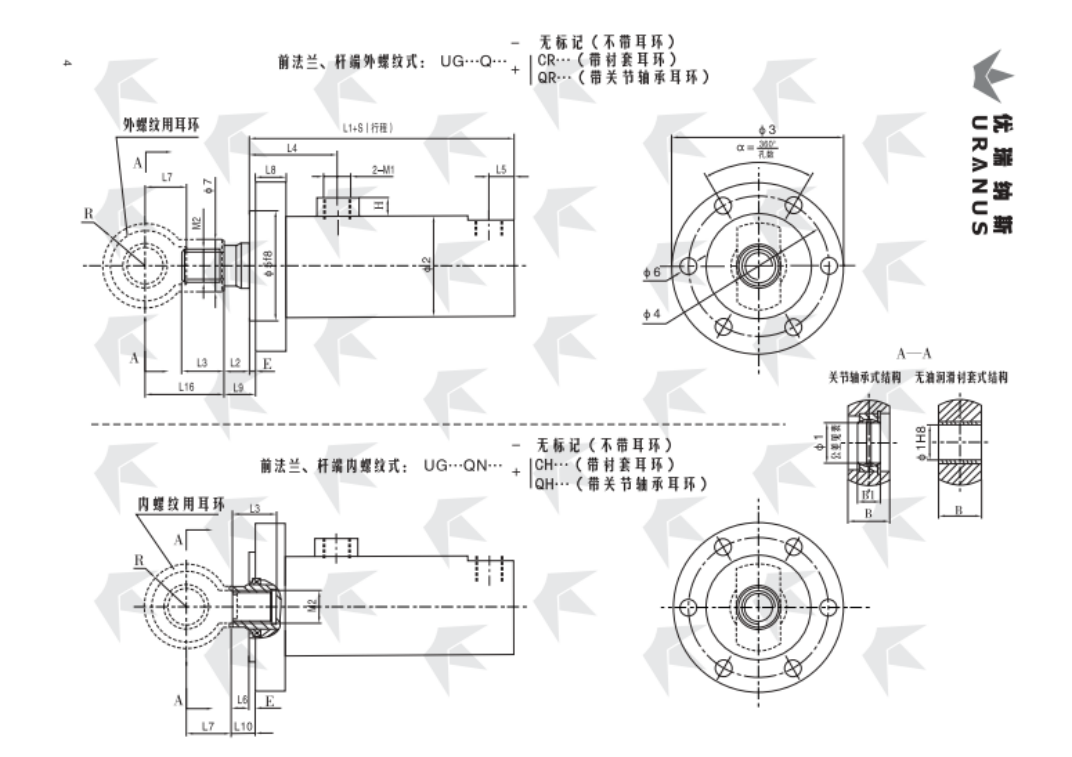

UG…Q front flange type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 holes ∅ 11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

21 |

15 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

23 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 holes ∅ 13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

25 |

25 |

20 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 holes ∅ 13.5 |

42 |

217 |

|

75 |

25 |

18 |

55 |

23 |

105 |

45 |

28 |

M30×2 |

80-1 |

|||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 holes ∅ 15.5 |

48 |

|

78 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 holes ∅ 18 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

30 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

||||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

257 |

55 |

90 |

90 |

135 |

M42×2 |

110-1 |

|||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

|||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 holes ∅ 18 |

68 |

267 |

60 |

104 |

87 |

40 |

140 |

M48×2 |

125-1 |

|||||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 holes ∅20 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 holes ∅ 22 |

76 |

297 |

70 |

119 |

110 |

157 |

M56×2 |

150-1 |

||||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

302 |

75 |

124 |

115 |

50 |

30 |

28 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 holes ∅ 24 |

90 |

343 |

|

85 |

129 |

122 |

40 |

|

90 |

35 |

|

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 holes ∅ 26 |

100 |

353 |

95 |

141 |

127 |

100 |

60 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 holes ∅ 29 |

110 |

393 |

|

105 |

146 |

143 |

50 |

|

110 |

70 |

|

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 holes ∅ 32 |

120 |

403 |

115 |

155 |

120 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

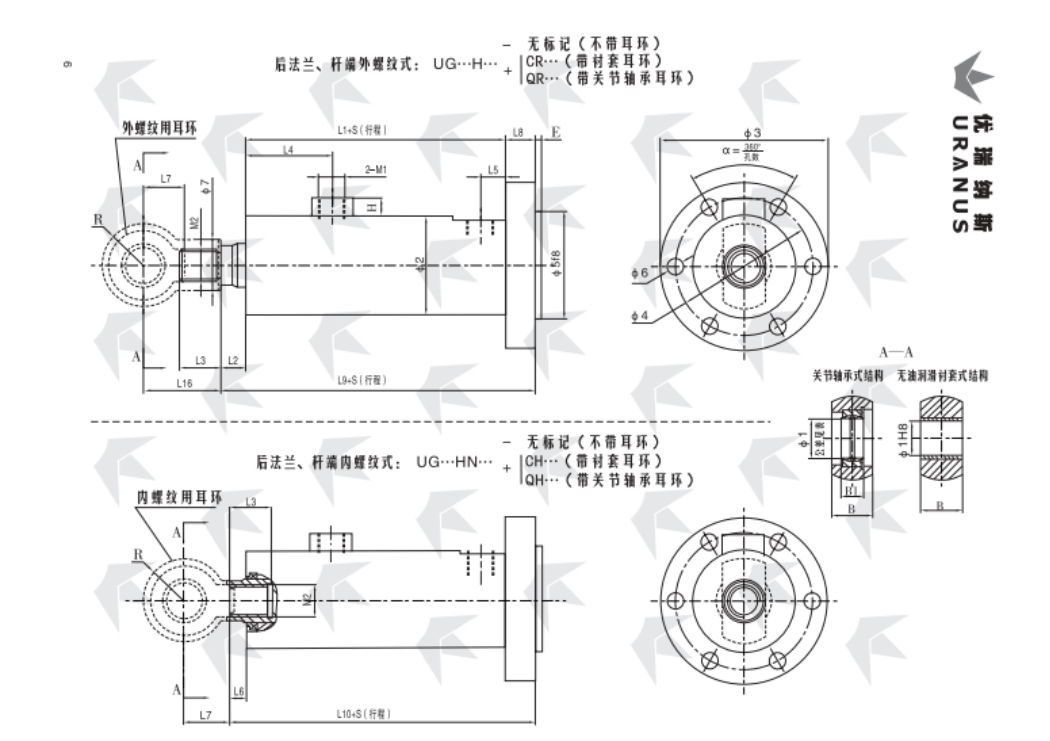

UG…H rear flange type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 holes ∅ 11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

203 |

197 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

208 |

200 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 holes ∅ 13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

25 |

245 |

240 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 holes ∅ 13.5 |

42 |

217 |

45 |

75 |

25 |

18 |

55 |

262 |

260 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 holes ∅ 15.5 |

48 |

78 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 holes ∅ 18 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

30 |

302 |

300 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

257 |

55 |

90 |

90 |

307 |

305 |

135 |

M42×2 |

110-1 |

|||||||||||||||||

63 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 holes ∅ 18 |

68 |

267 |

60 |

104 |

87 |

40 |

327 |

325 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 holes ∅ 20 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

352 |

350 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 holes ∅ 22 |

76 |

297 |

70 |

119 |

110 |

357 |

355 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

302 |

75 |

124 |

115 |

50 |

372 |

370 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 holes ∅ 24 |

90 |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

418 |

415 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 holes ∅ 26 |

100 |

353 |

95 |

141 |

127 |

100 |

60 |

438 |

435 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 holes ∅ 29 |

110 |

393 |

105 |

146 |

143 |

50 |

110 |

70 |

488 |

485 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

|||||||

125 |

120 140 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 holes ∅ 32 |

120 |

403 |

115 |

155 |

120 |

498 |

495 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

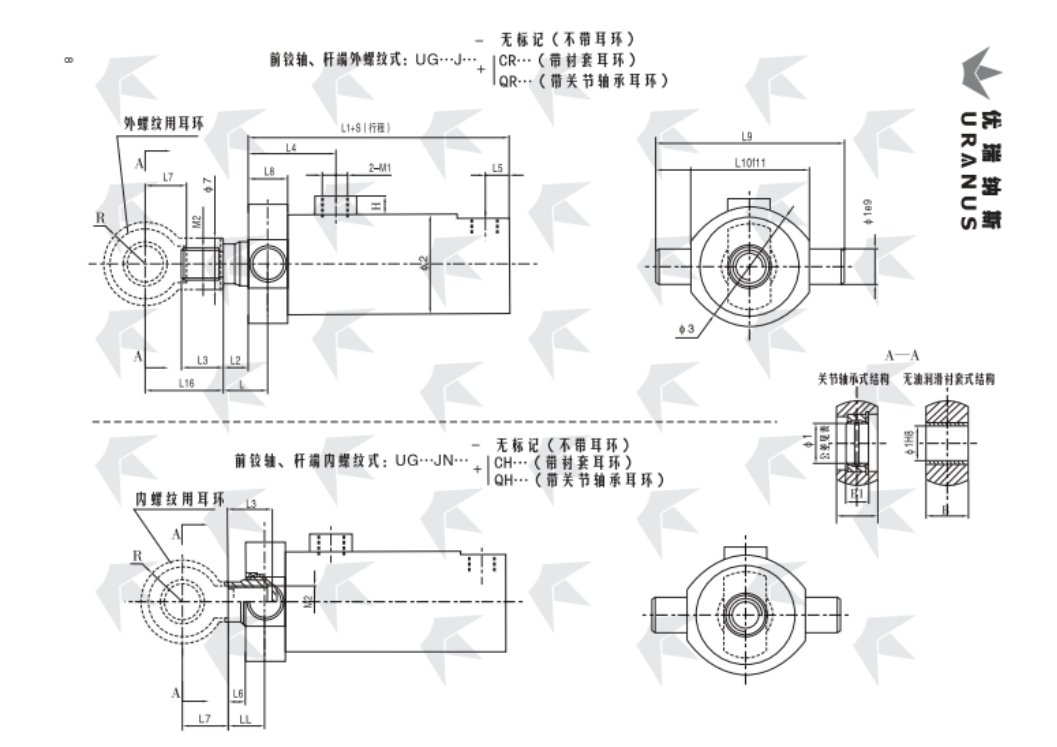

UG…J front hinge shaft type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

30 (24) |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

35 (27) |

170 |

18 |

30 |

58 |

20 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

37 (32) |

200 |

20 |

35 |

73 |

76 |

15 |

155 |

100 |

65 |

J5 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

42 (40) |

217 |

45 |

75 |

25 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

47 (45) |

252 |

50 |

89 |

85 |

30 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

257 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

267 |

60 |

104 |

87 |

35 |

260 |

185 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

52 (50) |

292 |

65 |

114 |

105 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

297 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

302 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

||||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

62 (59) |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

67 (64) |

353 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

72 (65) |

393 |

105 |

146 |

143 |

50 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

355 |

120 |

76 (73) |

403 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||

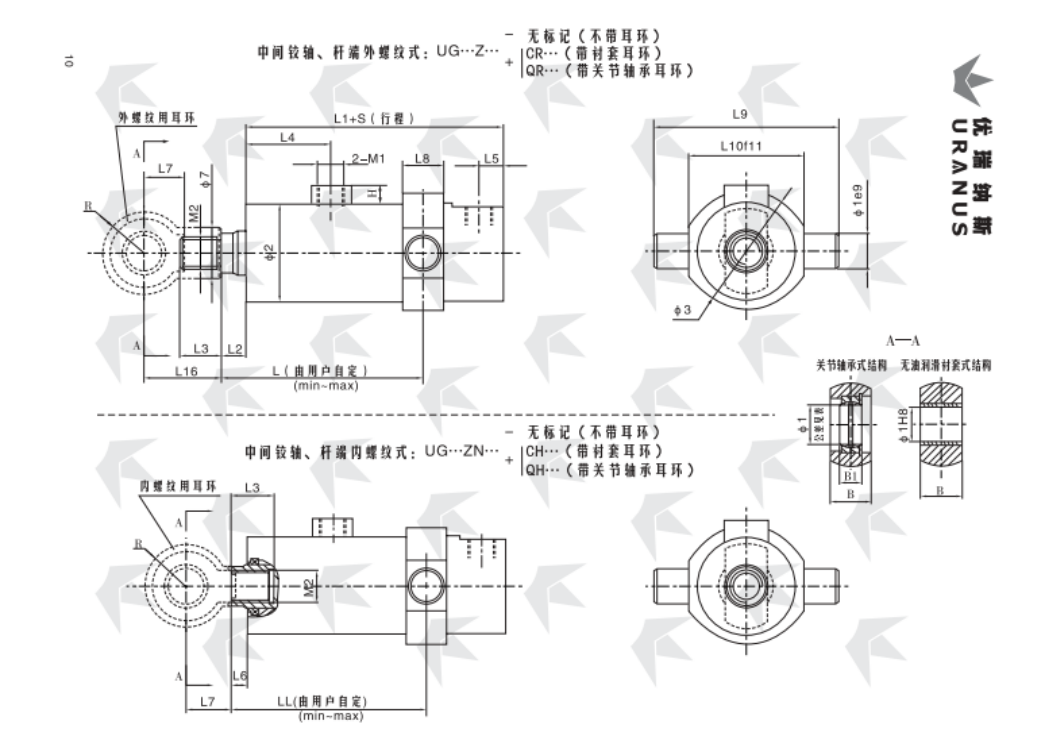

UG…Z intermediate hinge shaft type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

LI |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

||||||

Dimensions |

Bearing hole tolerance |

min |

max |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

|||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

124 (118) |

113+S (107+S) |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

129 (121) |

112+S (104+S) |

170 |

18 |

30 |

58 |

20 |

15 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

143 (138) |

132+S (127+S) |

200 |

20 |

35 |

73 |

76 |

155 |

100 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

142 (140) |

121+S (139+S) |

217 |

75 |

25 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

|||||||||||

M30×2 |

80-1 |

|||||||||||||||||||||||||||||

45 |

48 |

45 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

147 (145) |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

|||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

168 (166) |

149+S (147+S) |

252 |

50 |

89 |

85 |

30 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

169 (167) |

153+S (151+S) |

257 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

|||||||||||||||

63 |

68 |

M48 × 2 |

-2 |

|||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

183 (181) |

158+S (156+S) |

267 |

60 |

104 |

87 |

260 |

185 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

203 (201) |

175+S (173+S) |

292 |

65 |

114 |

105 |

35 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

208 (206) |

177+S (175+S) |

297 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

|||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

213 (211) |

182+S (180+S) |

302 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

233 (230) |

205+S (202+S) |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

250 (247) |

208+S (205+S) |

353 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

262 (259) |

225+S (222+S) |

393 |

105 |

146 |

143 |

50 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

335 |

120 |

275 (272) |

226+S (223+S) |

403 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||

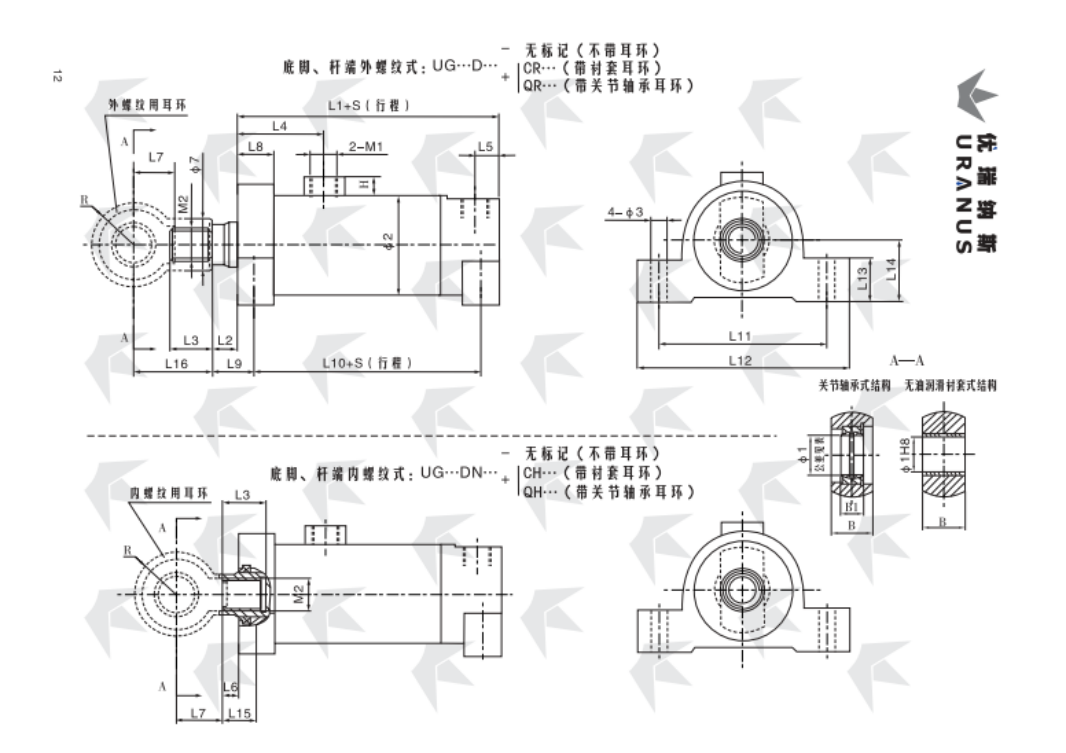

UG…D foot type

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L11 |

L12 |

L13 |

L14 |

L15 |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

||||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

25 |

28.5 |

142 |

105 |

130 |

25 |

40 |

22.5 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

30.5 |

145 |

120 |

150 |

30 |

45 |

22.5 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||||||

63 |

32 |

83 |

13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

30 |

35 |

170 |

140 |

175 |

35 |

50 |

30 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

17 |

42 |

217 |

45 |

75 |

25 |

18 |

55 |

40 |

40 |

177 |

160 |

200 |

40 |

60 |

38 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

185 |

230 |

45 |

70 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

||||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

21 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

45 |

42.5 |

207 |

205 |

255 |

50 |

80 |

40.5 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||||||

110 |

56 |

140 |

60 |

257 |

55 |

90 |

90 |

212 |

230 |

280 |

55 |

90 |

135 |

M42×2 |

110-1 |

||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||||||

125 |

63 |

152 |

25 |

68 |

267 |

60 |

104 |

87 |

55 |

47$ |

255 |

310 |

60 |

100 |

45.5 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

237 |

280 |

340 |

65 |

115 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||||||

150 |

75 |

180 |

76 |

297 |

70 |

119 |

110 |

60 |

50 |

295 |

355 |

67 |

120 |

48 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||||||

160 |

80 |

194 |

31 |

80 |

302 |

75 |

124 |

115 |

65 |

52.5 |

310 |

375 |

70 |

130 |

50.5 |

160 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

70 |

60 |

273 |

345 |

415 |

75 |

145 |

57 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

|||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

353 |

95 |

141 |

127 |

100 |

283 |

385 |

465 |

80 |

165 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

37 |

110 |

393 |

105 |

146 |

143 |

50 |

110 |

87 |

68.5 |

306 |

435 |

525 |

90 |

185 |

65.5 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

45 |

120 |

403 |

115 |

155 |

120 |

92 |

71 |

311 |

495 |

595 |

100 |

205 |

68 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||||||

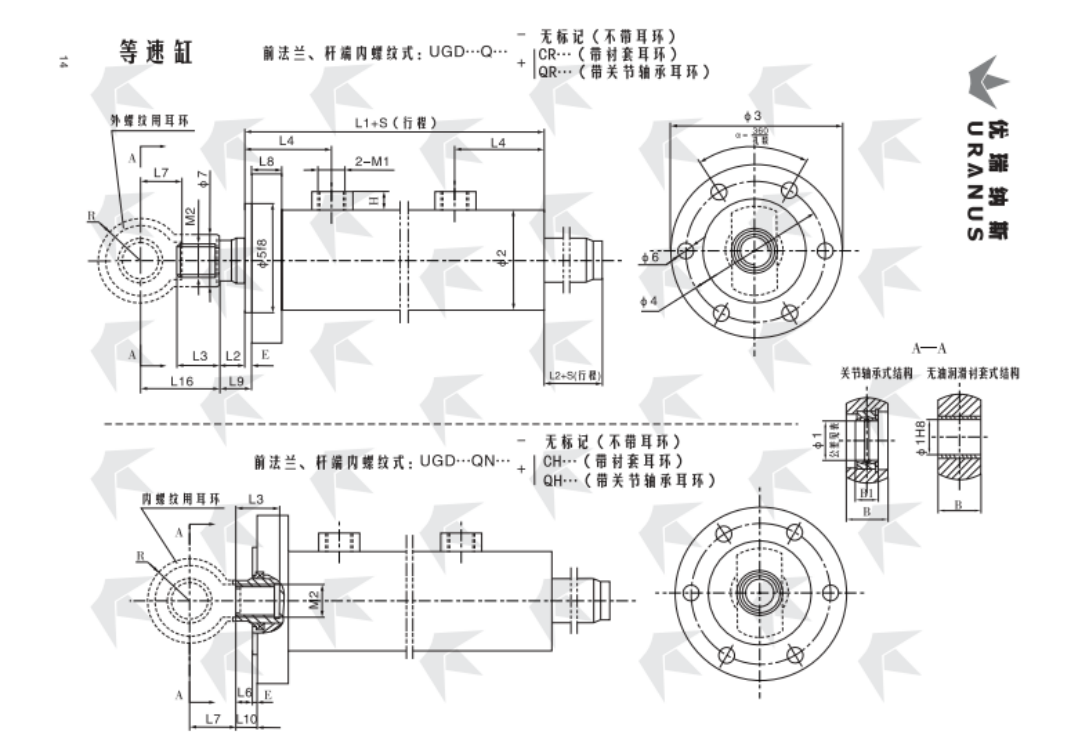

UGD…D front flange type constant velocity cylinder

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 holes ∅ 11 |

25 |

192 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

21 |

15 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14× 1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22× 1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

192 |

18 |

30 |

58 |

20 |

40 |

23 |

60 |

35 |

22 |

M20× 1.5 |

50-1 |

|||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 holes ∅ 13 |

35 |

232 |

20 |

35 |

73 |

76 |

15 |

25 |

25 |

20 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 holes ∅ 13.5 |

42 |

245 |

45 |

75 |

25 |

18 |

55 |

23 |

105 |

45 |

28 |

M30×2 |

80-1 |

|||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 holes ∅ 15.5 |

48 |

78 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 holes ∅ 18 |

52 |

275 |

50 |

89 |

85 |

30 |

70 |

30 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

||||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

285 |

55 |

90 |

90 |

135 |

M42×2 |

110-1 |

|||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

|||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 holes ∅ 18 |

68 |

298 |

60 |

104 |

87 |

40 |

140 |

M48×2 |

125-1 |

|||||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 holes ∅ 20 |

72 |

328 |

65 |

114 |

105 |

35 |

80 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 holes ∅ 22 |

76 |

333 |

70 |

119 |

110 |

157 |

M56×2 |

150-1 |

||||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

343 |

75 |

124 |

115 |

50 |

30 |

28 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 holes ∅ 24 |

90 |

376 |

|

85 |

129 |

122 |

40 |

|

90 |

35 |

32 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 holes ∅ 26 |

100 |

396 |

95 |

141 |

127 |

100 |

60 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 holes ∅ 29 |

110 |

436 |

|

105 |

146 |

143 |

50 |

|

110 |

70 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

|||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 holes ∅ 32 |

120 |

446 |

115 |

155 |

120 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

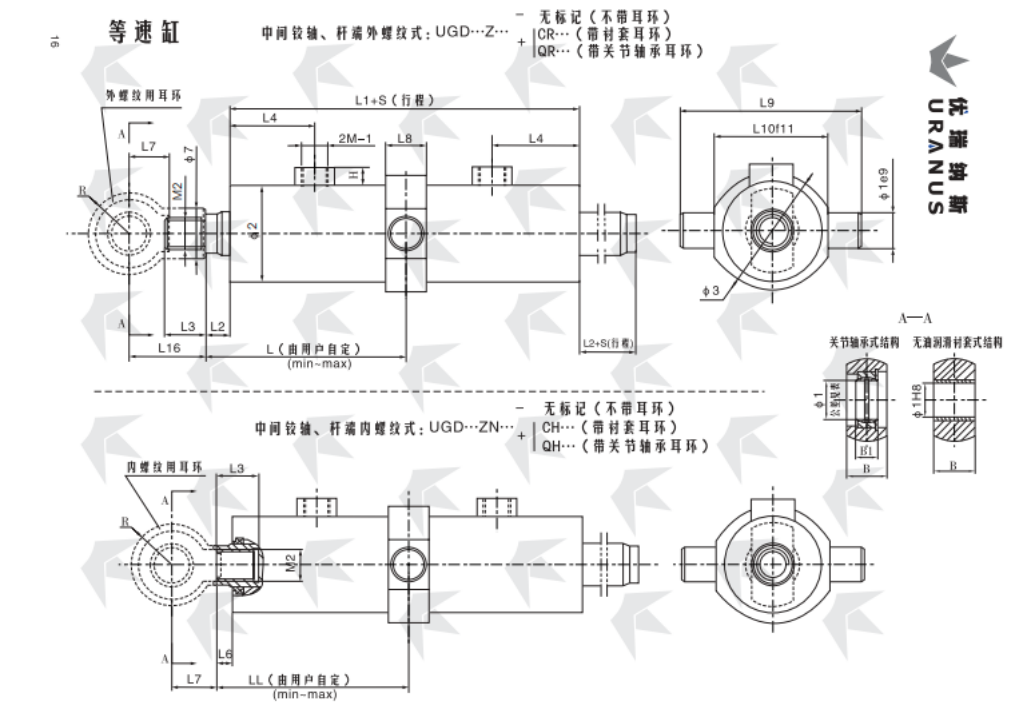

UGD…Z intermediate hinge shaft type constant velocity cylinder

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

L1 |

L2 |

L3 |

L4 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

||||||

Dimensions |

Bearing hole tolerance |

min |

max |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

124 (118) |

100+S (94+S) |

192 |

16 |

25 |

70 |

59 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

129 (121) |

99+S (91+S) |

192 |

18 |

30 |

58 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

143 (138) |

129+S (124+S) |

232 |

20 |

35 |

73 |

76 |

15 |

155 |

100 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

142 (140) |

143+S (141+S) |

245 |

45 |

75 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

147 (145) |

138+S (136+S) |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||

50 |

52 |

M36×2 |

-2 |

||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

168 (166) |

147+S (145+S) |

275 |

50 |

89 |

85 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

169 (167) |

156+S (154+S) |

285 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

183 (181) |

155+S (153+S) |

298 |

60 |

104 |

87 |

260 |

185 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

203 (201) |

165+S (163+S) |

328 |

65 |

114 |

105 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

208 (206) |

165+S (163+S) |

333 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

213 (211) |

170+S (168+S) |

343 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

233 (230) |

193+S (190+S) |

376 |

25 |

85 |

129 |

122 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

250 (247) |

196+S (193+S) |

396 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

262 (259) |

224+S (221+S) |

436 |

105 |

146 |

143 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

335 |

120 |

275 (272) |

221+S (218+S) |

446 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||

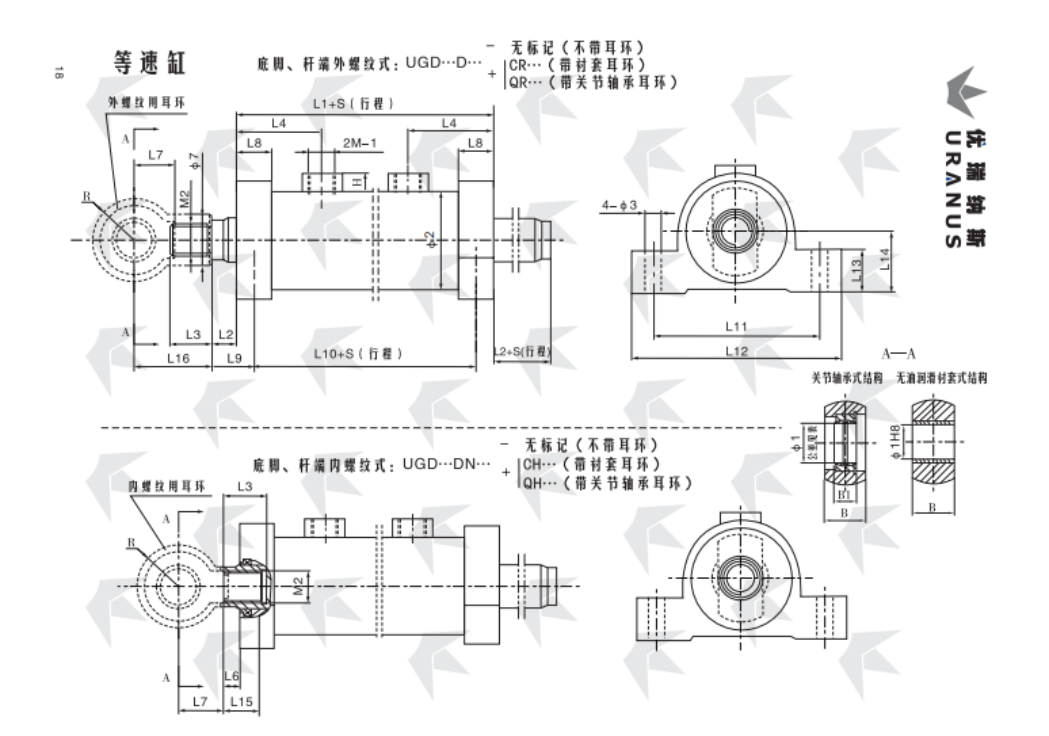

UGD…D foot type constant velocity cylinder

Cylinder diameter |

Rod diameter |

∅1 |

∅2 |

∅3 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L11 |

L12 |

L13 |

L14 |

L15 |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Rod end earring |

|||||

Dimensions |

Bearing hole tolerance |

Non-cushion |

Cushion Y |

CR |

QR |

CH |

QH |

||||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

11 |

25 |

192 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

25 |

28.5 |

167 |

105 |

130 |

25 |

40 |

22.5 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

192 |

18 |

30 |

58 |

20 |

40 |

30.5 |

167 |

120 |

150 |

30 |

45 |

22.5 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||||||

63 |

32 |

83 |

13 |

35 |

232 |

20 |

35 |

73 |

76 |

15 |

30 |

35 |

202 |

140 |

175 |

35 |

50 |

30 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

17 |

42 |

245 |

45 |

75 |

25 |

18 |

55 |

40 |

40 |

205 |

160 |

200 |

40 |

60 |

38 |

105 |

45 |

28 |

M30×2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

185 |

230 |

45 |

70 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||||

50 |

52 |

M36×2 |

-2 |

||||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

21 |

52 |

275 |

50 |

89 |

85 |

30 |

70 |

45 |

42.5 |

230 |

205 |

255 |

50 |

80 |

40.5 |

130 |

60 |

35 |

20 |

M27×2 |

M36×2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||||||

110 |

56 |

140 |

60 |

285 |

55 |

90 |

90 |

240 |

230 |

280 |

55 |

90 |

135 |

M42×2 |

110-1 |

||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||||||

125 |

63 |

152 |

25 |

68 |

298 |

60 |

104 |

87 |

55 |

47.5 |

243 |

255 |

310 |

60 |

100 |

45.5 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

328 |

65 |

114 |

105 |

35 |

80 |

273 |

280 |

340 |

65 |

115 |

155 |

70 |

44 |

|

M52×2 |

145-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||||||

100 |

100 |

M33×2 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

76 |

333 |

70 |

119 |

110 |

60 |

50 |

295 |

355 |

67 |

120 |

48 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||||||

160 |

80 |

194 |

31 |

80 |

343 |

75 |

124 |

115 |

65 |

52.5 |

278 |

310 |

375 |

70 |

130 |

50.5 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

376 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

70 |

60 |

306 |

345 |

415 |

75 |

145 |

57 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

|||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

396 |

95 |

141 |

127 |

100 |

326 |

385 |

465 |

80 |

165 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

37 |

110 |

436 |

105 |

146 |

143 |

50 |

110 |

87 |

68.5 |

349 |

435 |

525 |

90 |

185 |

65.5 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

45 |

120 |

446 |

115 |

155 |

120 |

92 |

71 |

354 |

495 |

595 |

100 |

205 |

68 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||||||