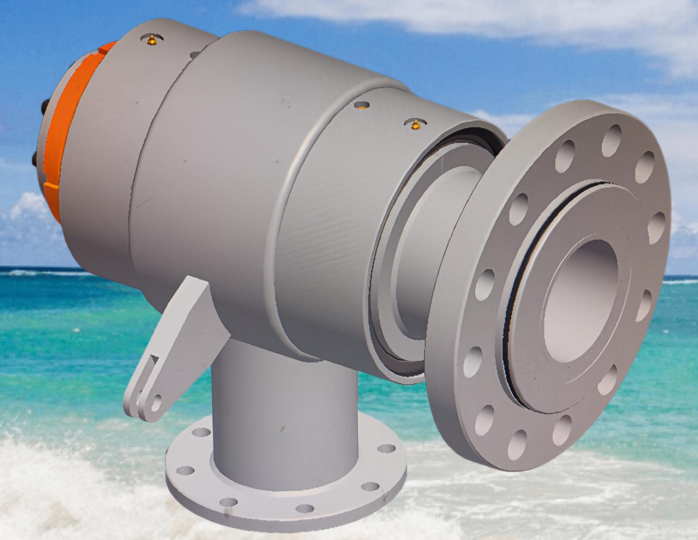

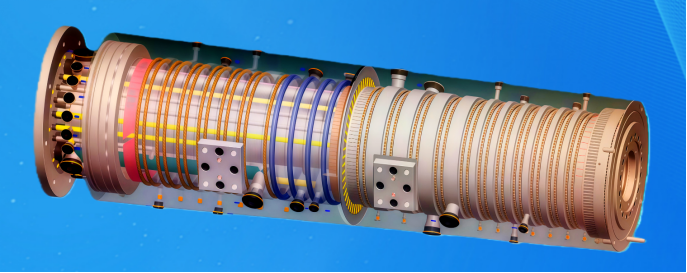

Hydraulic & Electrical Rotary Joints photo

(Customized Products for Ladle Turret Applications)

Hydraulic & Electrical Rotary Joints

(Customized Products for Ladle Turret Applications)

In steelmaking ladle turrets, hydraulic and electrical rotary joints are critical components ensuring continuous and safe operation.

They allow high-pressure fluids such as hydraulic oil, lubricants, cooling water, and gases to be transferred from stationary piping to rotating equipment, while also maintaining uninterrupted power and signal transmission.

Hydraulic rotary joints utilize advanced rotary sealing and multi-channel fluid transfer technology to achieve continuous delivery of high-pressure fluids between stationary and rotating platforms.

Electrical slip rings use precision silver-alloy contacts to ensure reliable transmission of power and signals.

When integrated together, these systems form a comprehensive “multi-media transmission channel” — the lifeline of automated steelmaking operations.

Tianjin Uranus Hydraulic Machinery Co., Ltd.

Specialized in manufacturing hydraulic rotary joints, electrical slip rings, high-pressure hydraulic cylinders, and servo actuators.

Customized design and drawing services are available upon request.

Working Principle

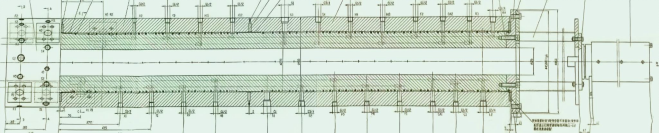

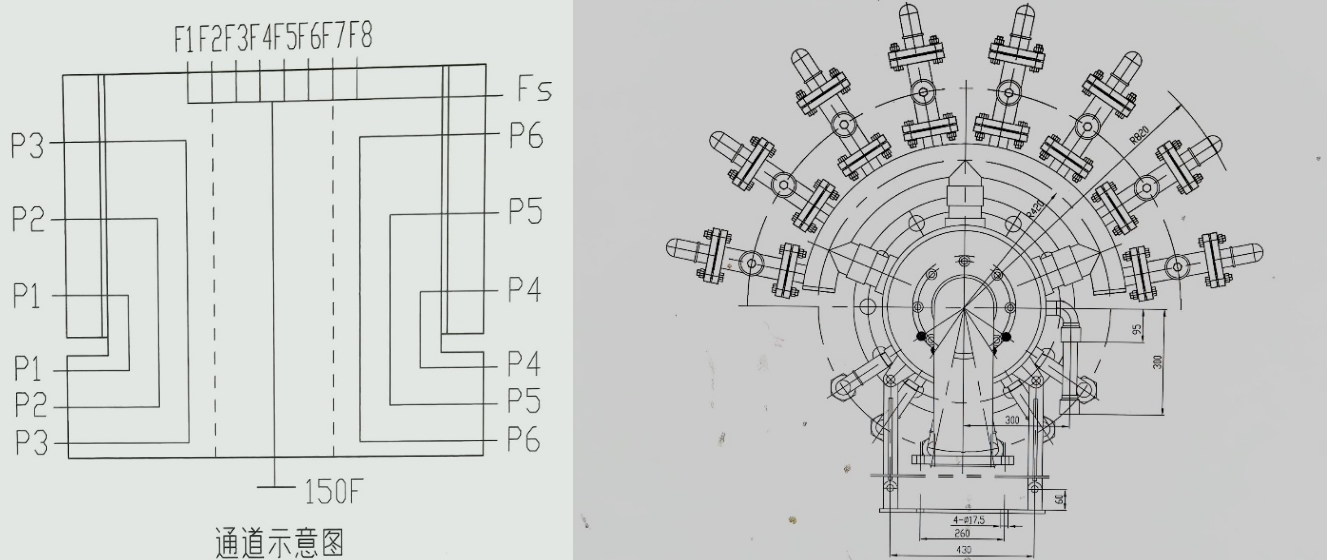

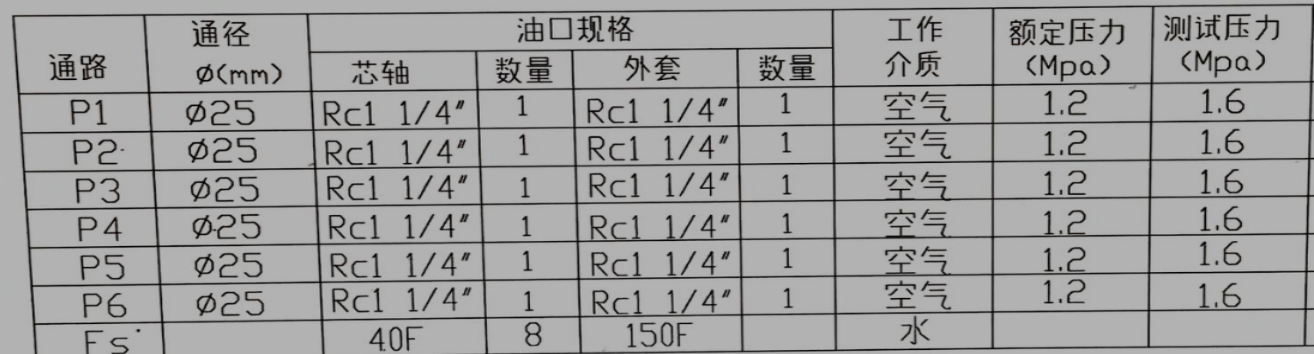

The hydraulic rotary joint is composed of a rotating housing and a stationary shaft core.The shaft connects to fixed pipelines, while the rotating housing moves synchronously with the turret, transmitting high-pressure fluids through sealed multi-channel paths. This ensures leak-free, long-life performance even under extreme operating conditions.

The electrical slip ring uses silver-alloy contacts and low-noise conductive paths to maintain continuous transmission of power, control, and sensor signals with low resistance fluctuation and high anti-interference capability.

Key Advantages

1. High-precision sealing – Multi-layer sealing ensures zero leakage under high pressure.

2. Precision manufacturing – CNC machining guarantees concentricity and sealing surface accuracy.

3. Low torque & smooth rotation – Reduces energy consumption and extends lifespan.

4. Full-scale testing – Every unit undergoes pressure, electrical, and durability testing before delivery.

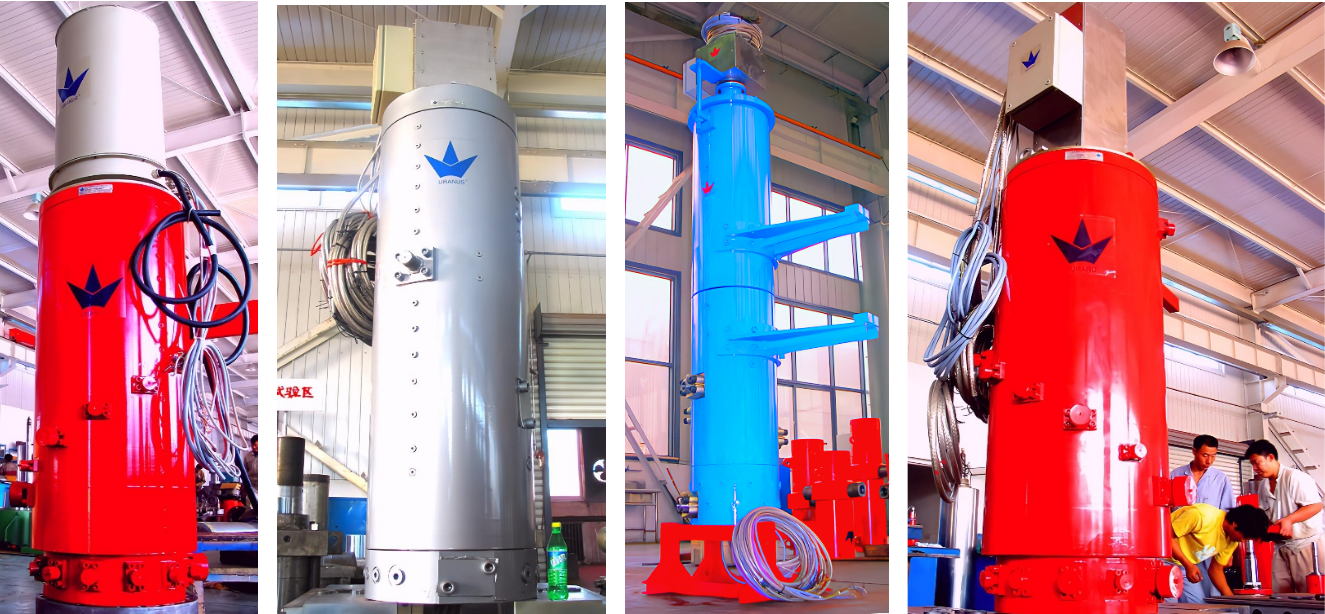

URANUS has delivered over a thousand customized rotary joints to global metallurgical enterprises, with many operating continuously in harsh environments for more than 20 years.

Product Examples

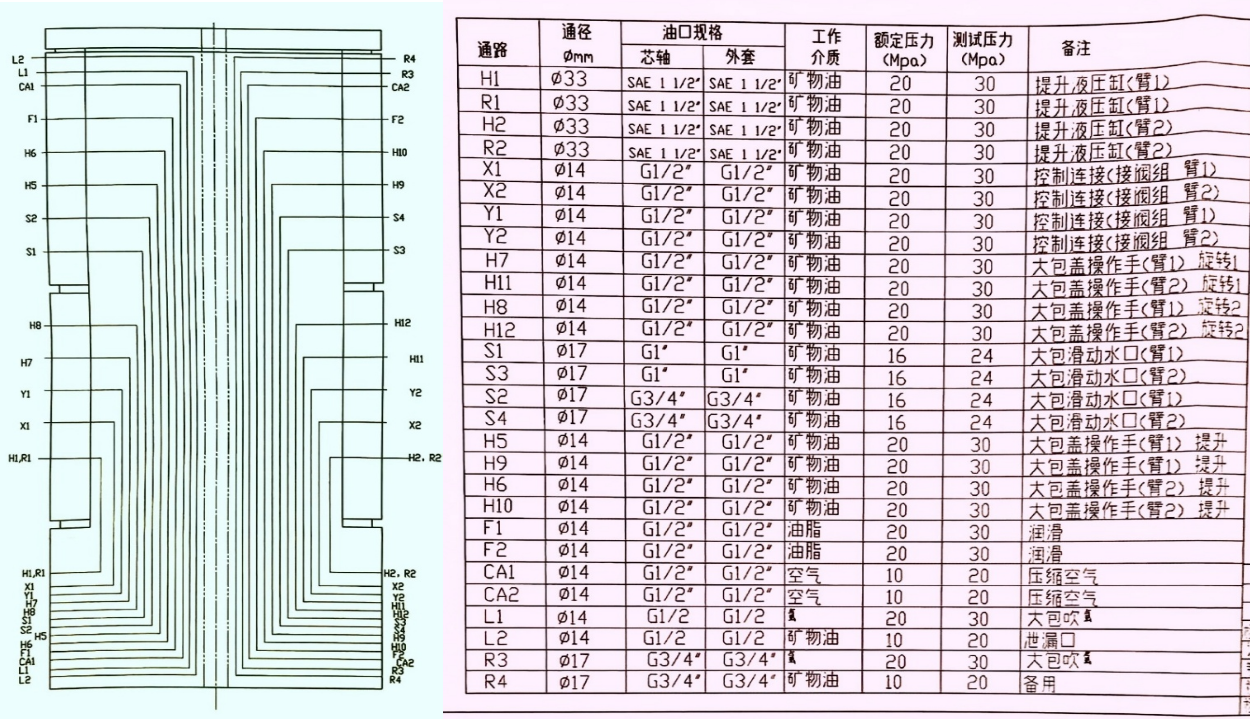

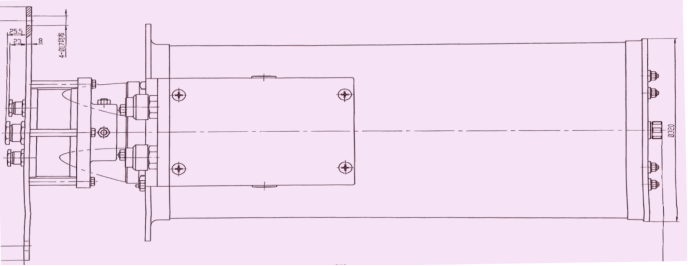

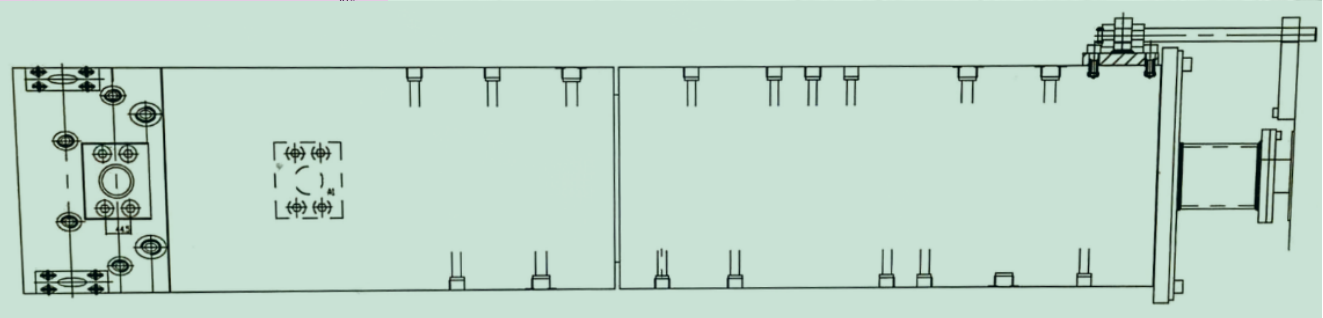

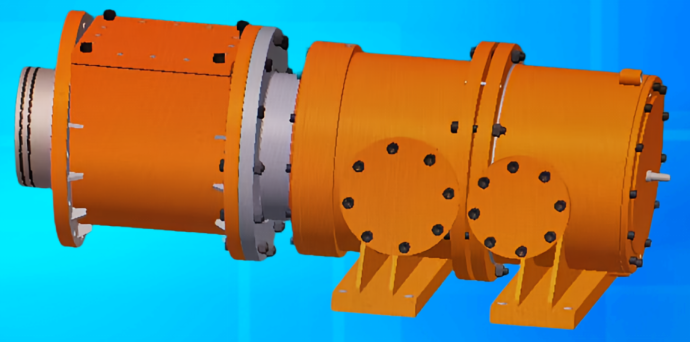

1. 28-Channel Hydraulic Slip Ring for Ladle Turret UX28 φ270X2-XG

Hydraulic Joint: Shaft Ø270 mm, 28 channels, 2 r/min.

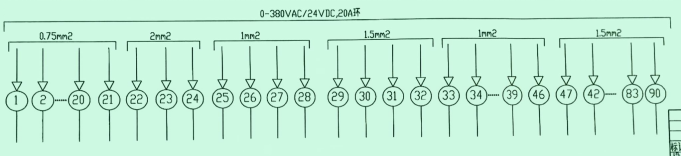

Electrical Slip Ring Specifications:

Voltage: 0-380VAC/24VDC

Current/Ring: 20A per ring, 90 rings

Insulation Strength: ≥500VAC@50Hz for 60 seconds

Dynamic Contact Resistance Fluctuation: ≤0.01Ω

Rotational Speed: 0-250 rpm

Electrical Contact Material: Silver alloy

Housing Material: Aluminum alloy

Feature: Fully sealed

Operating Temperature: -20°C to +80°C

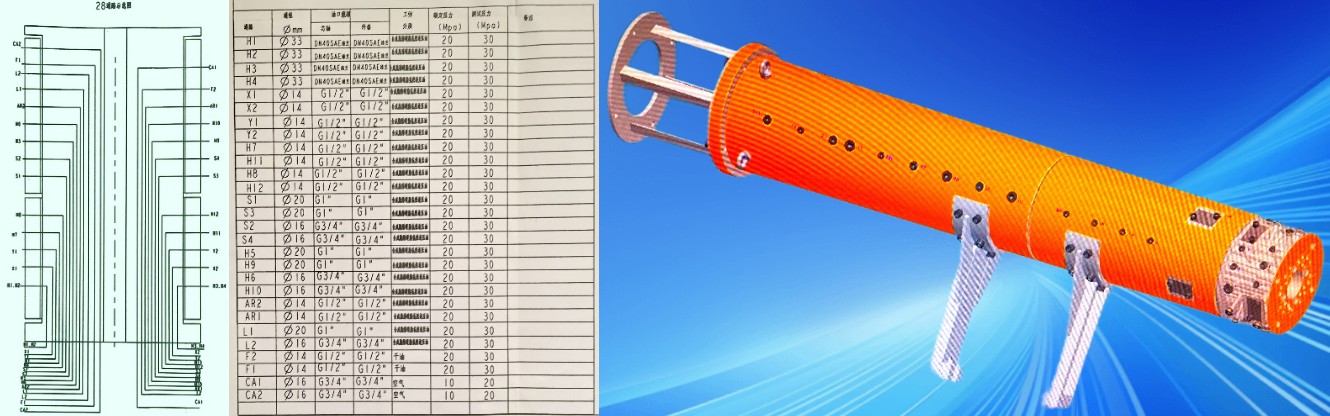

2、28-Channel Hydraulic Slip Ring for Ladle UX1504F28φ270X2X0701

Shaft Ø270 mm, 28 channels, 1 r/min.

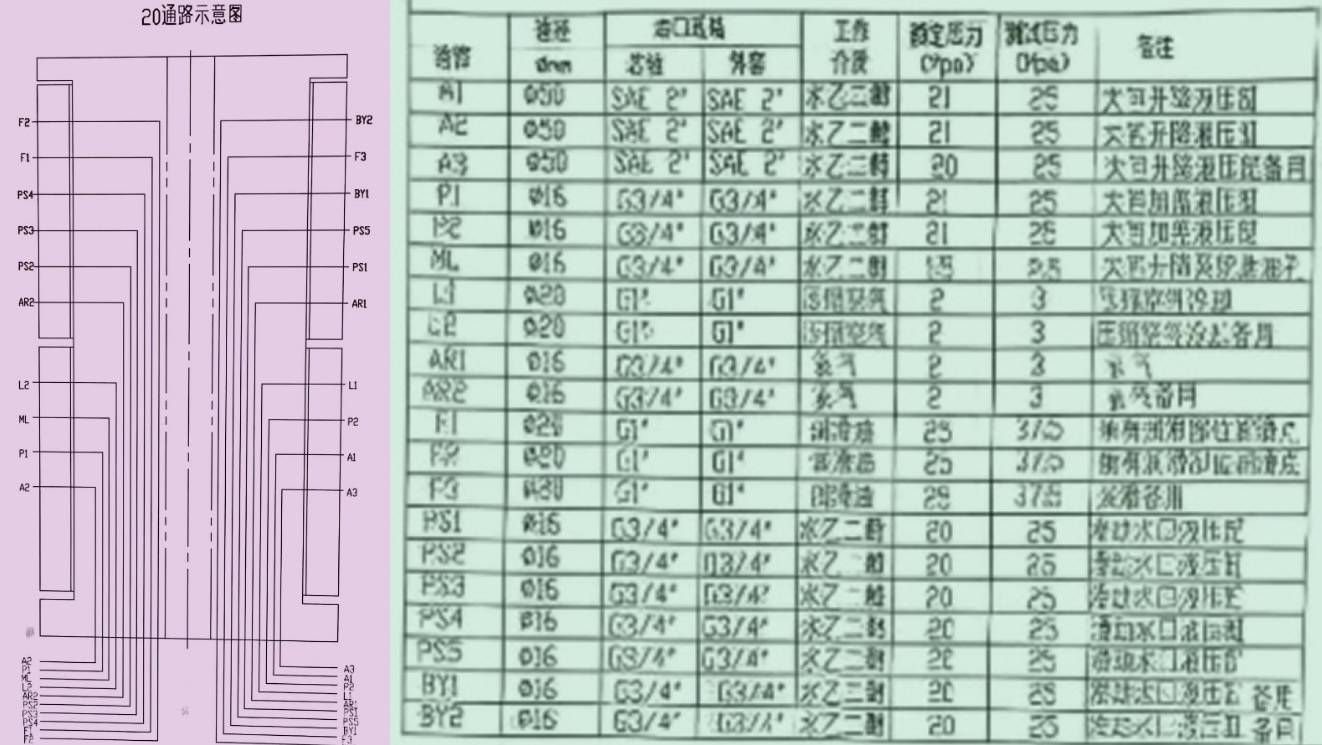

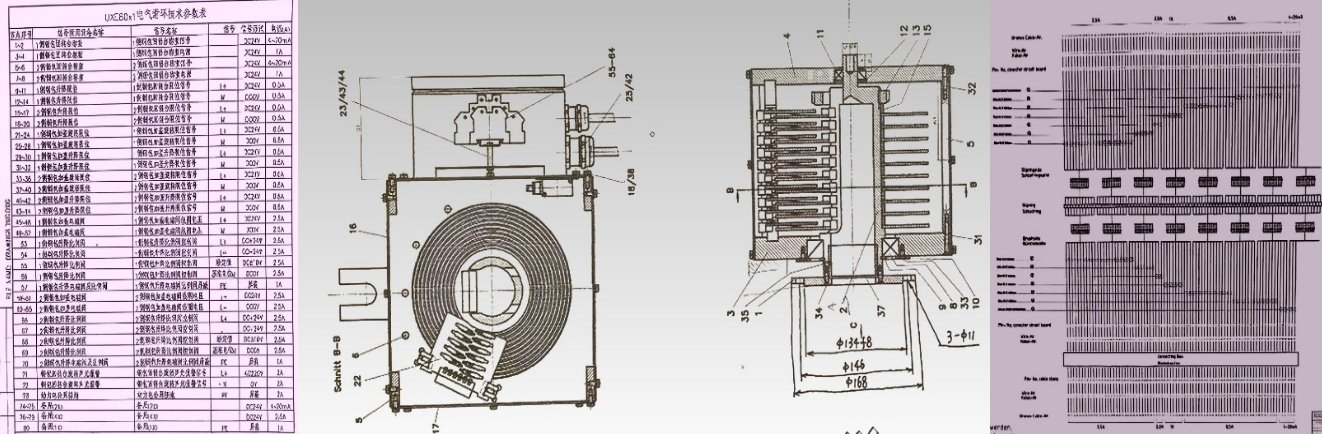

3、20-Channel Hydraulic Slip Ring for Ladle UX20φ250X2

Hydraulic Joint: Shaft Ø250 mm, 20 channels.:2r/min

Electrical Slip Ring Specifications:

Voltage: 0-380VAC/24VDC

Current/Ring: 0.5-2.5A per ring,4-20mA per ring, 80 rings

Insulation Strength: ≥500VAC@50Hz for 60 seconds

Dynamic Contact Resistance Fluctuation: ≤0.01Ω

Rotational Speed: 0-250 rpm

Electrical Contact Material: Silver alloy

Housing Material: Aluminum alloy

Operating Temperature: -20°C to +80°C

4、14-Channel Hydraulic Slip Ring UX14φ320X2

Hydraulic Joint: Shaft Ø320 mm, 14 channels. 2r/min

Electrical Slip Ring Specifications:

Voltage: 0-220VAC/24VDC

Current/Ring: 0.5-2.5A per ring, 124 rings

Insulation Strength: ≥500VAC@50Hz for 60 seconds

Dynamic Contact Resistance Fluctuation: ≤0.01Ω

Electrical Contact Material: Silver alloy

Housing Material: Aluminum alloy

Operating Temperature: -20°C to +80°C

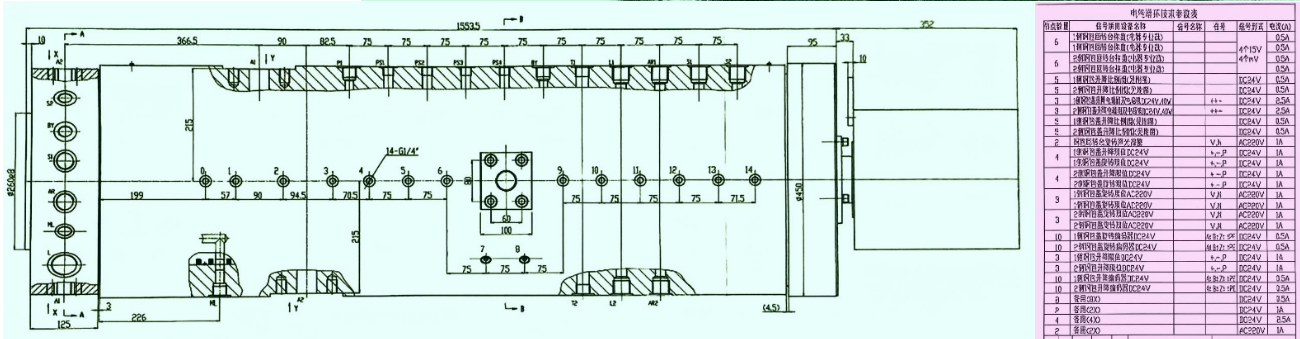

5、14-Channel Hydraulic Slip Ring UX12Dφ320X2

Shaft Ø320 mm, 12 channels, 2 r/min.

Electrical Slip Ring Specifications:

Voltage: 0-380VAC/24VDC Current/Ring: 0.5-2.5A per ring, 124 rings

Insulation Strength: ≥500VAC@50Hz for 60 seconds

Dynamic Contact Resistance Fluctuation: ≤0.01Ω

Electrical Contact Material: Silver alloy Housing Material: Aluminum alloy

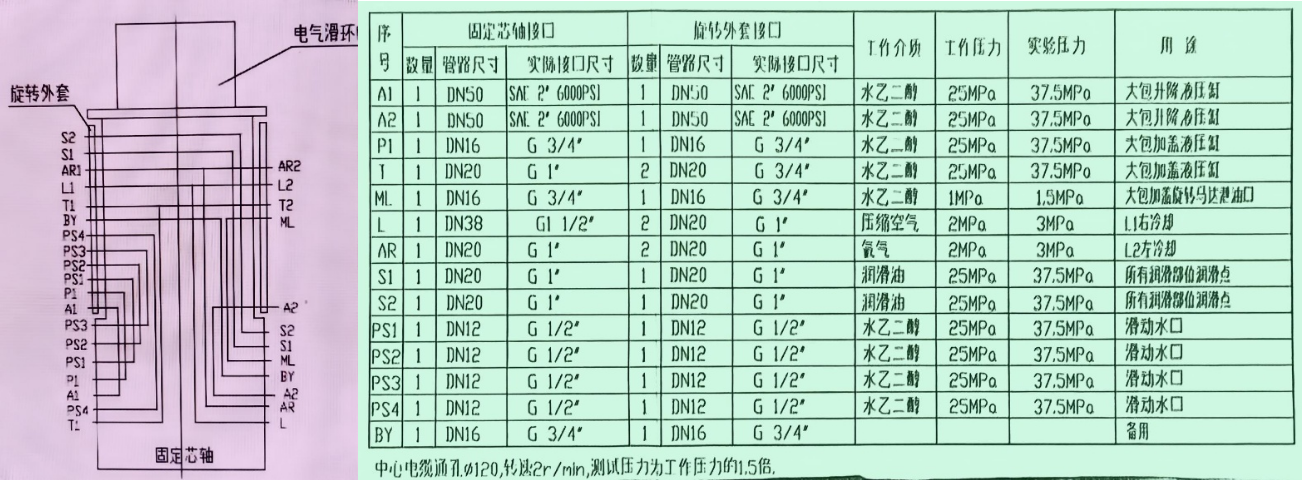

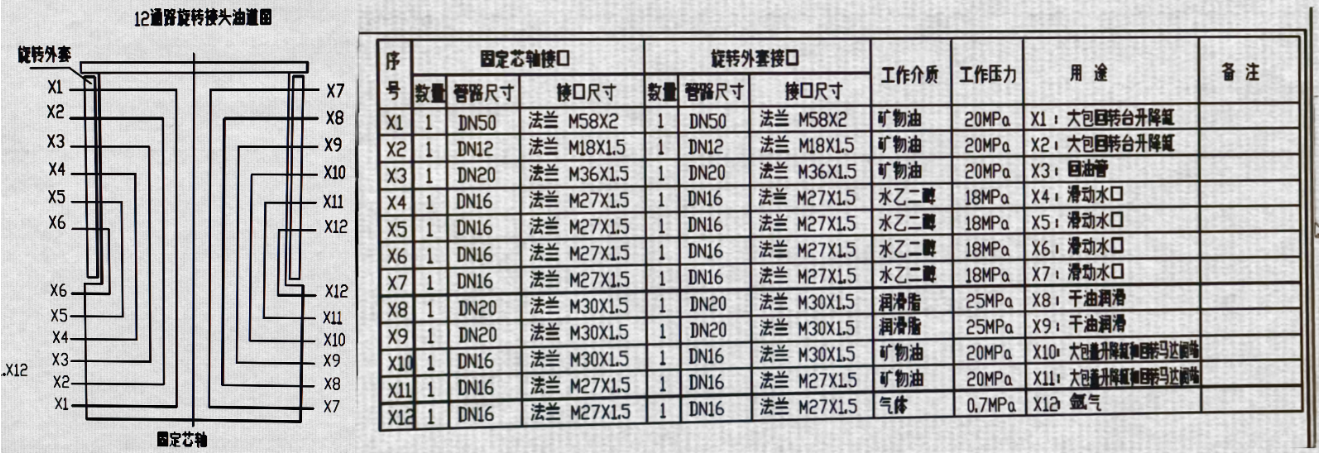

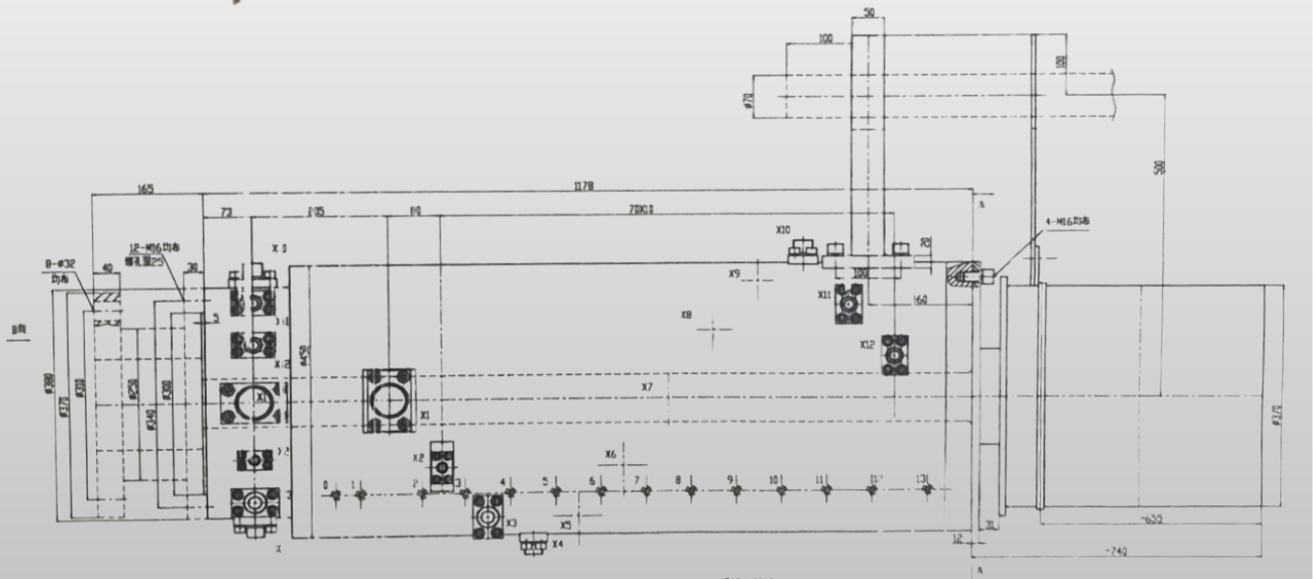

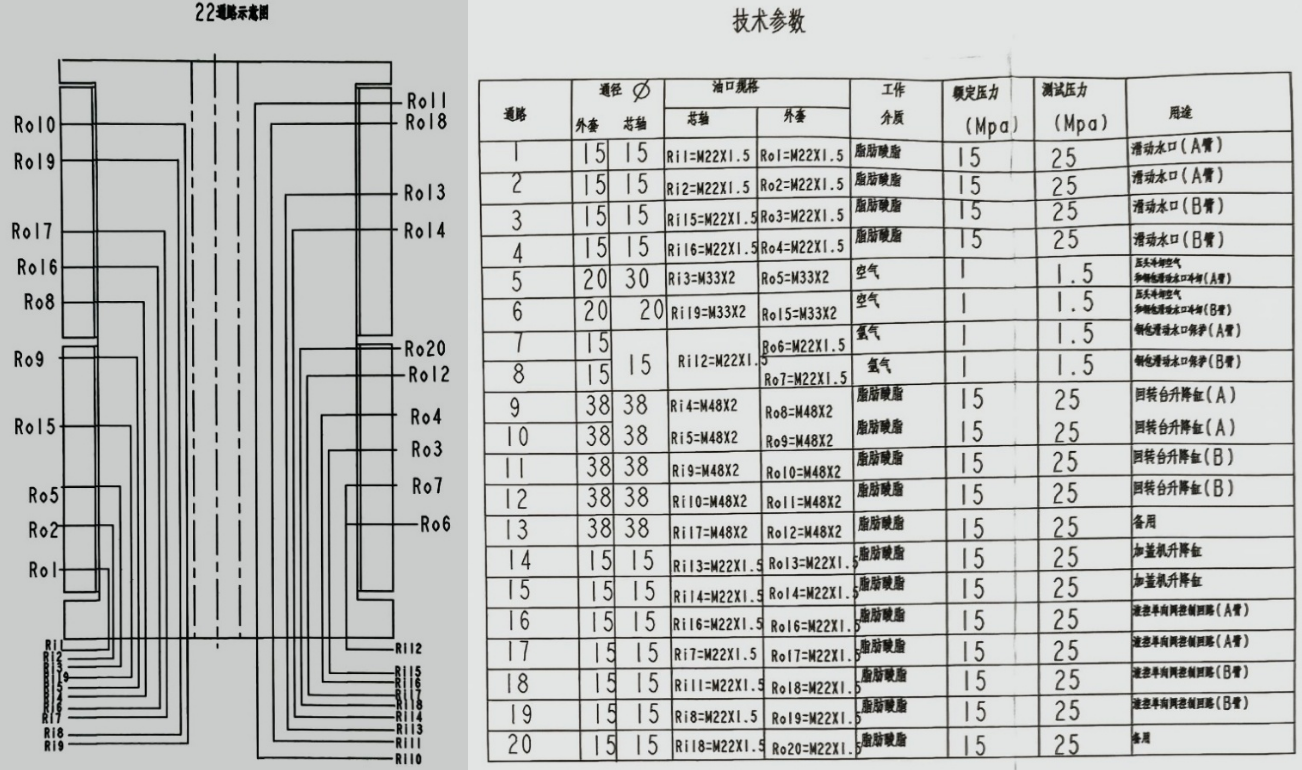

6、Slip Ring UX22φ320X2

Shaft Ø320 mm, 22 channels, 2 r/min.

7、Rotary Joint for Converter Non-Driving Side UX7φ360X2

Shaft Ø360 mm, 7 channels.2r/min

8、Rotary Joint for No.3 Converter Tilting Driving Side UX2φ270X2

Shaft Ø270 mm, 2 channels,2r/min medium: water,

working pressure: 1MPa. Testing Pressure: 1.5MPa

9、Rotary Joint (Converter Non-Driving Side)UX1φ200X2

Shaft Ø200 mm, 1 channel, bore Ø150 mm,2r/min

medium: water, working pressure: 0.9MPa. Testing Pressure:1.5MPa