In important fields such as metallurgical heavy duty industry, engineering machinery, ships and vessels, aerospace, etc., there is a widespread need for hydraulic cylinders to be reliably locked and easily unlocked at a certain position within the stroke range for a long time. The hydraulic cylinder is usually locked by hydraulic sealing of the oil circuit, but due to the problem of internal and external leakage, long-term locking may result in positioning slippage and movement.

The hydraulic cylinder piston rod lock relies on the static friction force between the conical friction ring and the piston rod to achieve mechanical locking, which can effectively prevent piston rod slip caused by leakage in the hydraulic circuit, achieve high-precision and long-term positioning locking function, and work safely and reliably. The conical friction ring is usually provided with locking force by a butterfly spring; The locking force can also be provided by a hydraulic piston, and this locking method requires the hydraulic oil of the hydraulic piston to use static pressure holding method. The locking device is unlocked by hydraulic pressure, and the unlocking operation is simple, fast, and reliable.

The Uranus hydraulic cylinder piston rod lock is a product independently designed and developed by the company in 1994. During the design process, finite element analysis was conducted on the structural dimensions, materials used, and finite element force analysis of the lock components. Simulation calculations were performed on butterfly springs, seals, pistons, and other components. Type and load life tests were also conducted on the prototype. For over 30 years, Uranus has provided thousands of hydraulic cylinder piston rod locks of various specifications and models to customers in various industries without any quality accidents.

The hydraulic cylinder piston rod locking device is usually manufactured and used in conjunction with the hydraulic cylinder, or can be used independently, all of which are customized according to customer needs.

Here are several examples of piston rod locking devices:

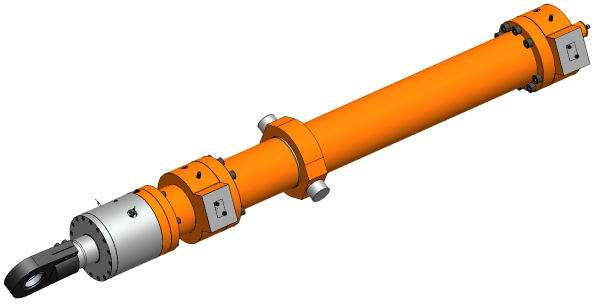

1.Hydraulic cylinder with locking device locking form: hydraulic locking hydraulic unlocking

Hydraulic cylinder technical parameters: cylinder diameter: 280 rod diameter: 200 stroke: 1900, including two end buffer stroke: 80 each

Work pressure: 35MPa Test pressure: 52.5MPa Built in displacement sensor

Clamping device technical parameters: Locking rod diameter: 200, maximum locking stroke of 10, maximum unlocking stroke of 11

Locking pressure: 14MPa Locking force: 2000KN Locking test pressure: 21MPa

3D outline drawing

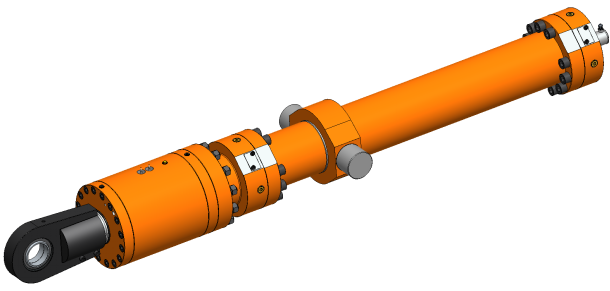

2.Hydraulic cylinder with locking device locking form: butterfly spring locking hydraulic unlocking

Hydraulic cylinder technical parameters: cylinder diameter: 250 rod diameter: 160 stroke: 1900, including two end buffer stroke: 70 each

Work pressure: 25MPa Test pressure: 37.5MPa Built in displacement sensor

Clamping device technical parameters: Locking rod diameter: 160, maximum locking stroke of 13, maximum unlocking stroke of 13

Locking pressure: 7MPa Locking force: 600KN Locking test pressure: 10.5MPa

3D outline drawing

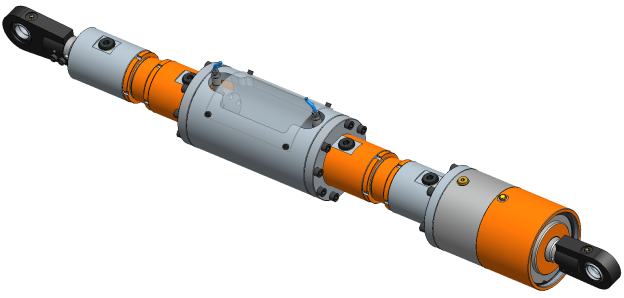

3.Double cylinder series connection with locking device hydraulic cylinder locking form: butterfly spring locking hydraulic unlocking

Hydraulic cylinder technical parameters: (cylinder diameter: 63 rod diameter: 45 stroke: 100)+(cylinder diameter: 63 rod diameter: 45 stroke: 100)

Work pressure: 12MPa Test pressure: 16MPa Built in displacement sensor

Clamping device technical parameters: Locking rod diameter: 45, maximum locking stroke of 5, maximum unlocking stroke

Locking force: 75KN Unlocking pressure: 10.5MPa Unlocking test pressure: 12MPa

3D outline drawing

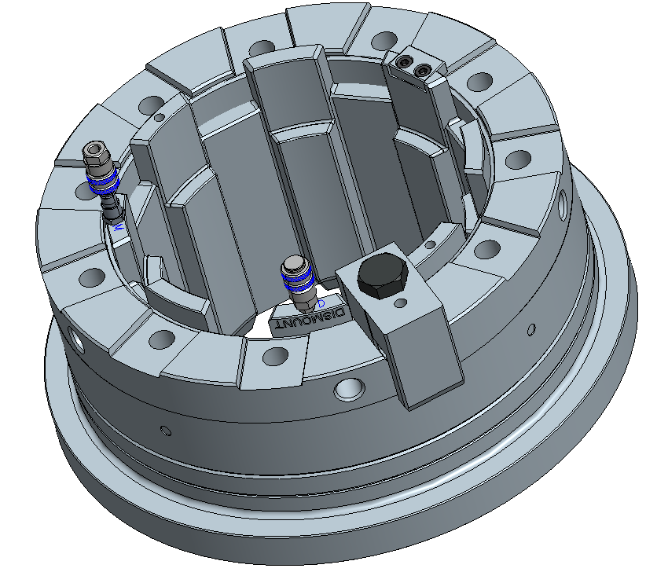

4.8-jaw locking device locking form: hydraulic locking hydraulic unlocking

Technical parameters: locking cylinder diameter: 360, locking hole diameter: 320, locking piston stroke: 40,

Work pressure: 14MPa Test pressure: 21MPa

3D outline drawing