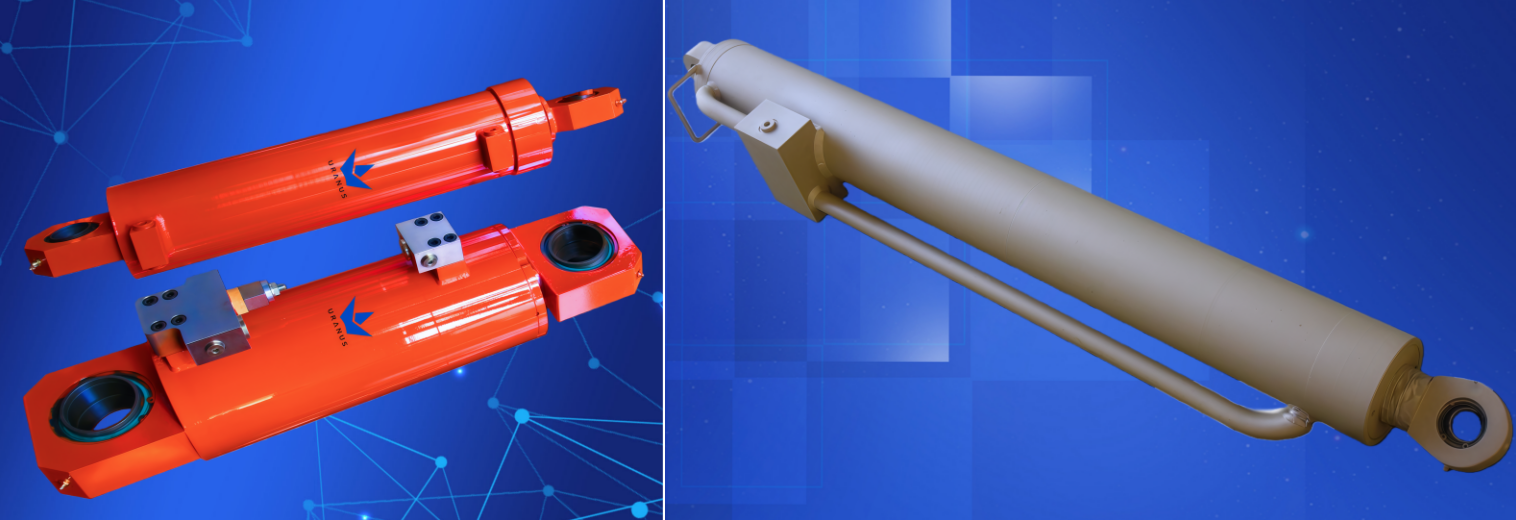

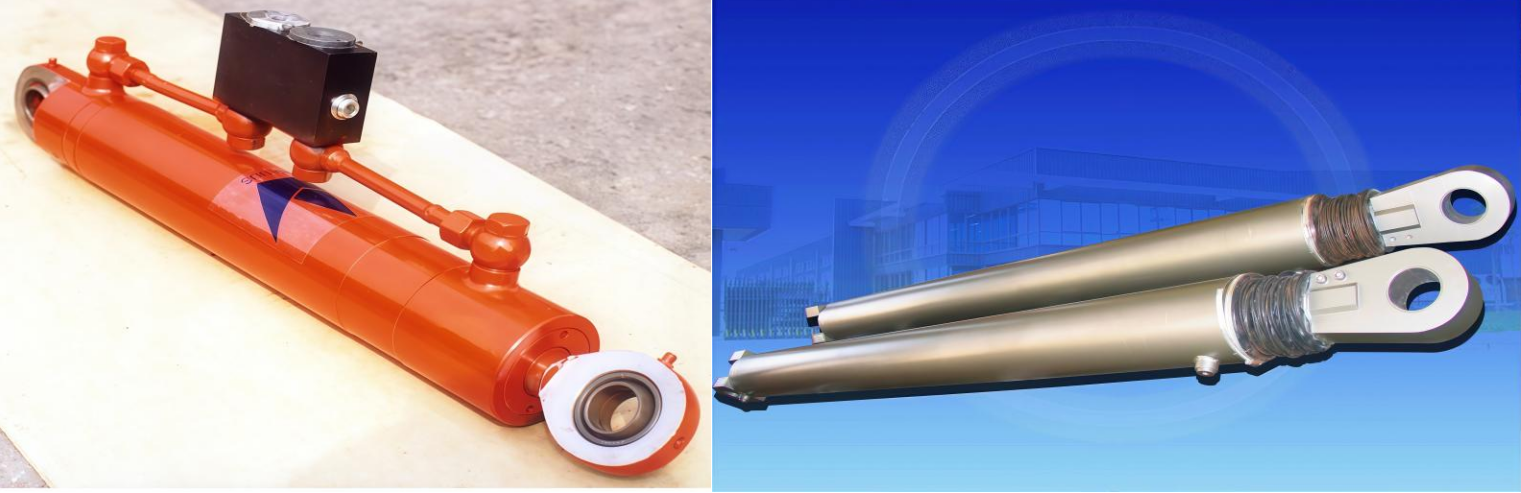

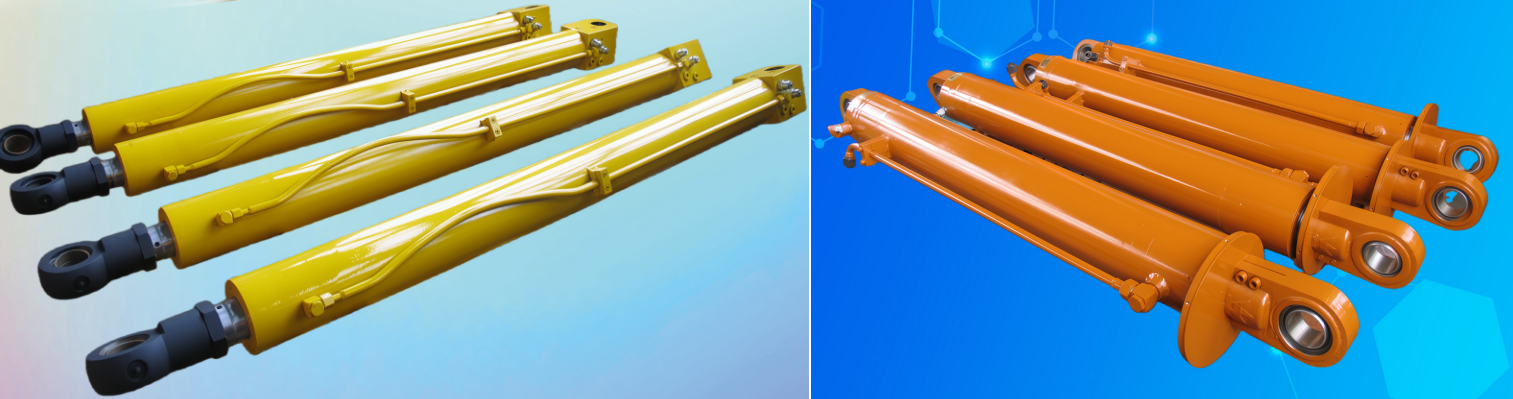

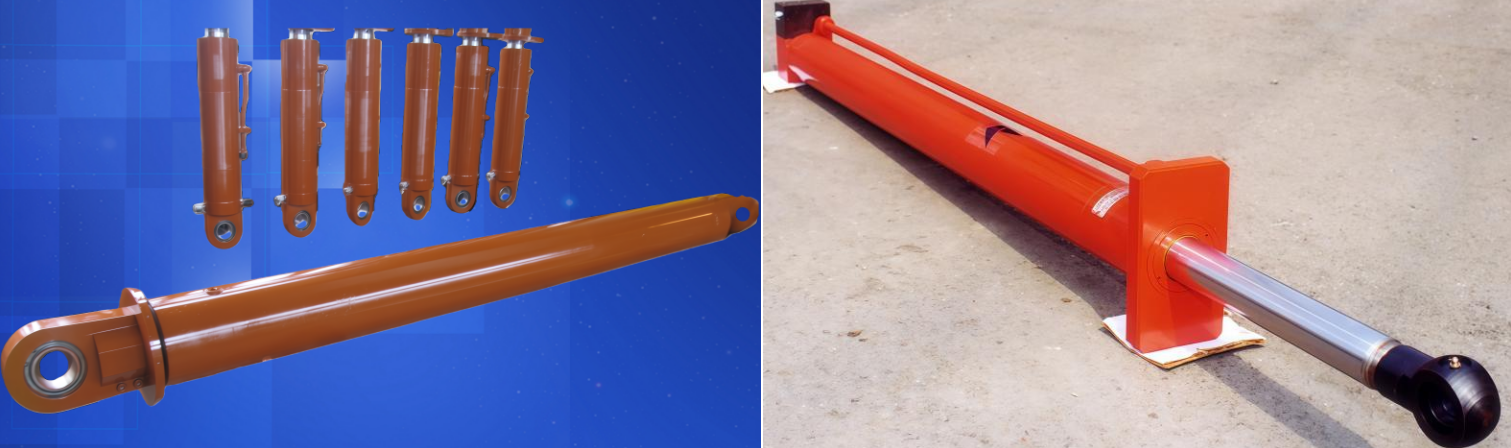

Mga Larawan ng Construction Machinery Hydraulic Cylinder

UG Series Medium & High Pressure Hydraulic Cylinders

Isang Standardisadong Platform para sa Hydraulic Cylinder na Batay sa Mga Dekada ng Custom Engineering Experience

Pangkalahatang-ideya ng Produkto

Ang UG Series medium at high-pressure hydraulic cylinders ay isinasaayos nang mag-isa ni Uranus Hydraulic batay sa mahabang karanasan sa malawakang produksyon ng custom hydraulic cylinder sa loob ng maraming dekada.

Idinisenyo sa isang standardisadong istrukturang platform habang pinapanatili ang mataas na modularidad at fleksibilidad sa konpigurasyon, ang serye ng UG ay angkop para sa mga makinarya sa konstruksyon, kagamitang pang-industriya, at matitibay na aplikasyon. Matagumpay na pinagsama ng seryeng ito ang kakayahang engineering na custom kasama ang standardisadong produksyon sa industriya, nagbibigay ng matatag na pagganap, mataas na katiyakan, at mahabang buhay ng serbisyo.

Mga Pangunahing Tiyak at Konpigurasyon

Mga Uri ng Paggana

Mga Estilo ng Pagkakabit

・Harapang clevis mount

・Mid clevis mount

・Front flange mount

・Rear flange mount

・Foot mount

Koneksyon sa Dulo ng Bariles

・Naka-thread na dulo ng bariles

・Self-lubricating bushing eye

・Spherical bearing eye

Rating at Sukat ng Presyon

・Rating ng presyon: 16 MPa / 21 MPa

・Diyametro ng bore: φ40 – φ250 mm (15 sukat)

・Diyametro ng rod: φ20 – φ180 mm (23 sukat)

・Pinakamataas na stroke: hanggang 10 m (nakasubok sa kondisyon ng katatagan ng rod)

Kakayahan sa Paggawa

Mahahalagang bahagi ng UG Series hydraulic cylinders—kabilang ang piston rods, cylinder tubes, pistons, cylinder heads, at end caps—ay ginawa gamit ang mga precision CNC machining center at kontrolado sa ilalim ng mahigpit na pamamaraan ng pamamahala ng kalidad.

Ang lahat ng cylinder ay mayroong mga sealing system na mataas ang kakayahang lumaban sa pagkasira at mababa ang friction, na nagagarantiya ng matatag na operasyon sa ilalim ng mataas na karga, impact, at mahihirap na kondisyon ng paggamit.

Pagsusuri ng Kalidad at Pagsusuri

Bawat UG Series hydraulic cylinder ay dumaan sa komprehensibong pagsusuri ng pagganap bago maipadala, na nakatuon sa:

・Walang panlabas na pagtagas

・Mataas na kahusayan sa mekanikal

・Mahusay na paglaban sa pagkaugod at pagbibrilyon

・Matagal ang buhay ng serbisyo

Ang lahat ng guhit ng produkto, talaan ng pagsusuri, at ulat ng pagsusulit ay iniimbak para sa higit sa 10 taon , tinitiyak ang buong traceability at pagpapatunay ng kalidad.

Panghabambuhay na Komitment sa Kalidad

Para sa anumang mga isyu sa kalidad na dulot ng disenyo o mga depekto sa pagmamanupaktura, Ang Uranus Hydraulic ay nag-aalok ng panghabambuhay libreng pagkukumpuni o kapalit, na nagbibigay ng pangmatagalang katiyakan at tiwala sa mga customer.

Tungkol sa Uranus Hydraulic

Itinatag noong 1995, ang Uranus Hydraulic ay isang teknolohikal na tagagawa na dalubhasa sa mga de-kalidad na produkto sa hydraulic transmission at mekatronikong kagamitang may pinagsamang mekanika, hydraulics, optics, at electronics.

Ang kumpanya ay may higit sa 50,000 hanay ng mga custom na drawing ng produkto, nasa loob higit sa 100 pambansang patent para sa imbensyon at utility model , at gumagamit ng software sa 3D parametric design, mga sistema sa PDM na pamamahala sa buhay ng produkto, at patuloy na binabago ang mga sistema sa ERP.

Sertipikado ang Uranus Hydraulic ayon sa ISO 9001, ISO 14001, at ISO 45001, at ang mga produkto nito ay malawakang pinagkakatiwalaan ng mga customer sa buong mundo dahil sa kanilang teknikal na kahusayan at pare-parehong kalidad.

Kaugnay na Serye ng Produkto

・UY Series Heavy-Duty & Metallurgy Hydraulic Cylinders (25 MPa)

・US Series Servo Cylinders with Integrated Magnetostrictive Sensors

・UB Series Rack & Pinion Rotary Hydraulic Cylinders

・UX Series High-Pressure Multi-Passage Rotary Joints

・UP Series Hydraulic Power Units

・UF Series Synchronous Distributor Hydraulic Cylinder

・UE Electro-hydraulic cylinders

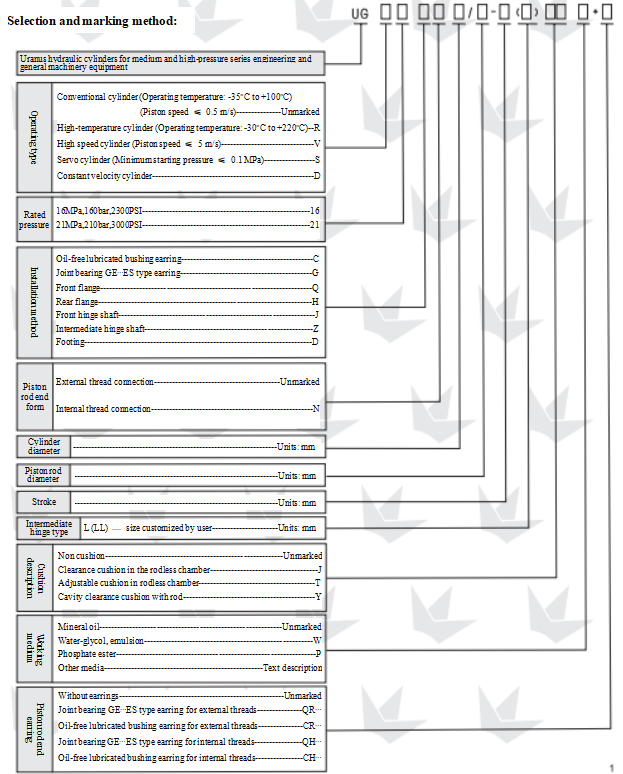

UG Medium and High-Pressure Series Engineering and General Machinery Equipment Hydraulic Cylinders

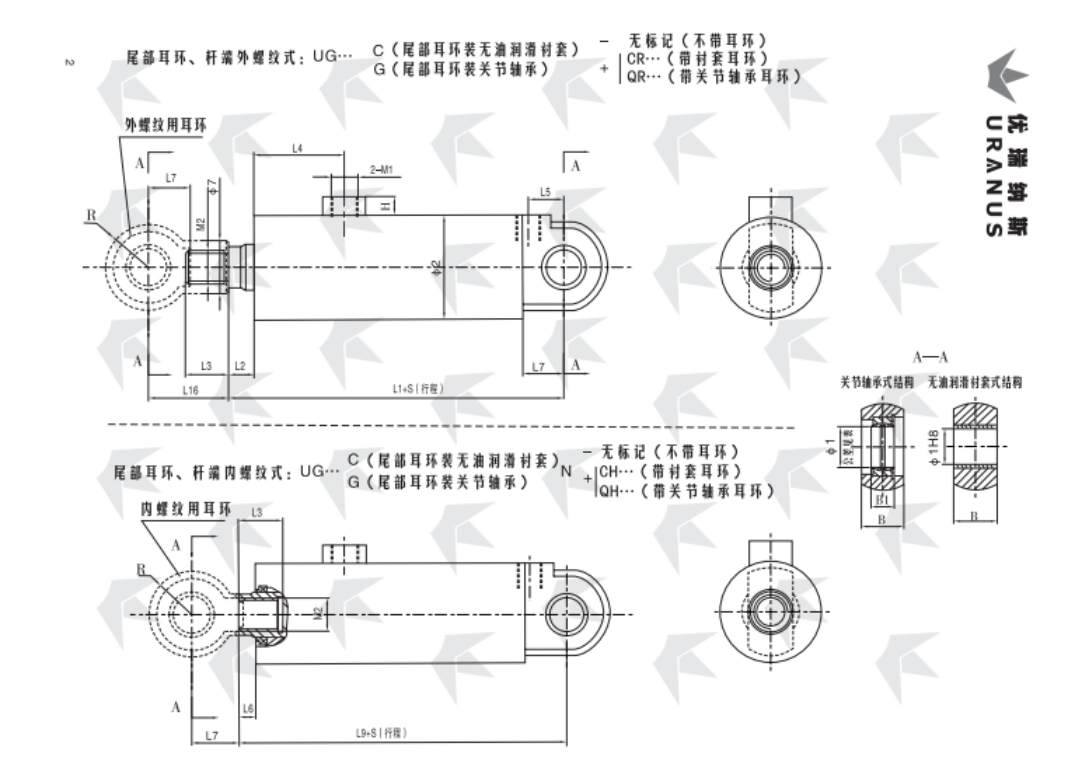

UG...C...free lubricated bushing earring type, UG...G...joint bearing (GE..ES type) uri ng tainga

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L9 |

L16 |

R |

B |

B1 |

H |

M |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

25 |

200 |

16 |

25 |

70 |

59 |

30 |

10 |

30 |

190 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

205 |

18 |

30 |

58 |

35 |

40 |

195 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||

63 |

32 |

83 |

35 |

245 |

20 |

35 |

73 |

76 |

40 |

15 |

235 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

42 |

260 |

45 |

75 |

45 |

18 |

55 |

255 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

110 |

M33×2 |

90-1 |

||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||

100 |

50 |

50 |

127 |

52 |

300 |

50 |

89 |

85 |

55 |

70 |

295 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||

110 |

56 |

140 |

60 |

305 |

55 |

90 |

90 |

300 |

135 |

M42×2 |

110-1 |

||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||

125 |

63 |

152 |

68 |

315 |

60 |

104 |

87 |

310 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

345 |

65 |

114 |

105 |

65 |

80 |

340 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||

150 |

75 |

180 |

76 |

350 |

70 |

119 |

110 |

345 |

157 |

M56×2 |

150-1 |

||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||

160 |

80 |

194 |

80 |

355 |

75 |

124 |

115 |

350 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

410 |

25 |

85 |

129 |

122 |

75 |

22 |

90 |

400 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

430 |

95 |

141 |

127 |

85 |

100 |

420 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

110 |

465 |

105 |

146 |

143 |

90 |

110 |

455 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||

250 |

125 |

100 |

299 |

120 |

485 |

115 |

155 |

100 |

120 |

475 |

245 |

110 |

70 |

M95×3 |

250-1 |

||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||

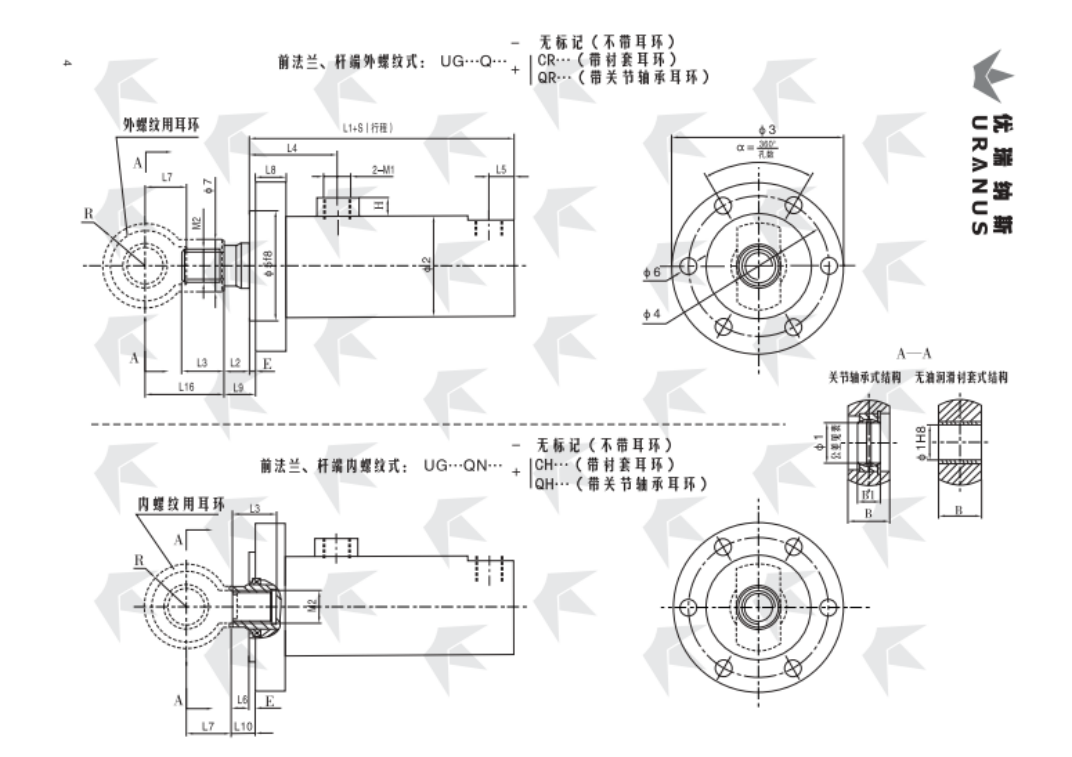

UG…Q harapang uri ng flange

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 na butas ∅ 11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

21 |

15 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

23 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 na butas ∅ 13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

25 |

25 |

20 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 butas ∅ 13.5 |

42 |

217 |

|

75 |

25 |

18 |

55 |

23 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

|||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 butas ∅ 15.5 |

48 |

|

78 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 butas ∅ 18 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

30 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

||||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

257 |

55 |

90 |

90 |

135 |

M42×2 |

110-1 |

|||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

|||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 butas ∅ 18 |

68 |

267 |

60 |

104 |

87 |

40 |

140 |

M48×2 |

125-1 |

|||||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 butas ∅20 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 butas ∅ 22 |

76 |

297 |

70 |

119 |

110 |

157 |

M56×2 |

150-1 |

||||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

302 |

75 |

124 |

115 |

50 |

30 |

28 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 butas ∅ 24 |

90 |

343 |

|

85 |

129 |

122 |

40 |

|

90 |

35 |

|

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 butas ∅ 26 |

100 |

353 |

95 |

141 |

127 |

100 |

60 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 butas ∅ 29 |

110 |

393 |

|

105 |

146 |

143 |

50 |

|

110 |

70 |

|

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 butas ∅ 32 |

120 |

403 |

115 |

155 |

120 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

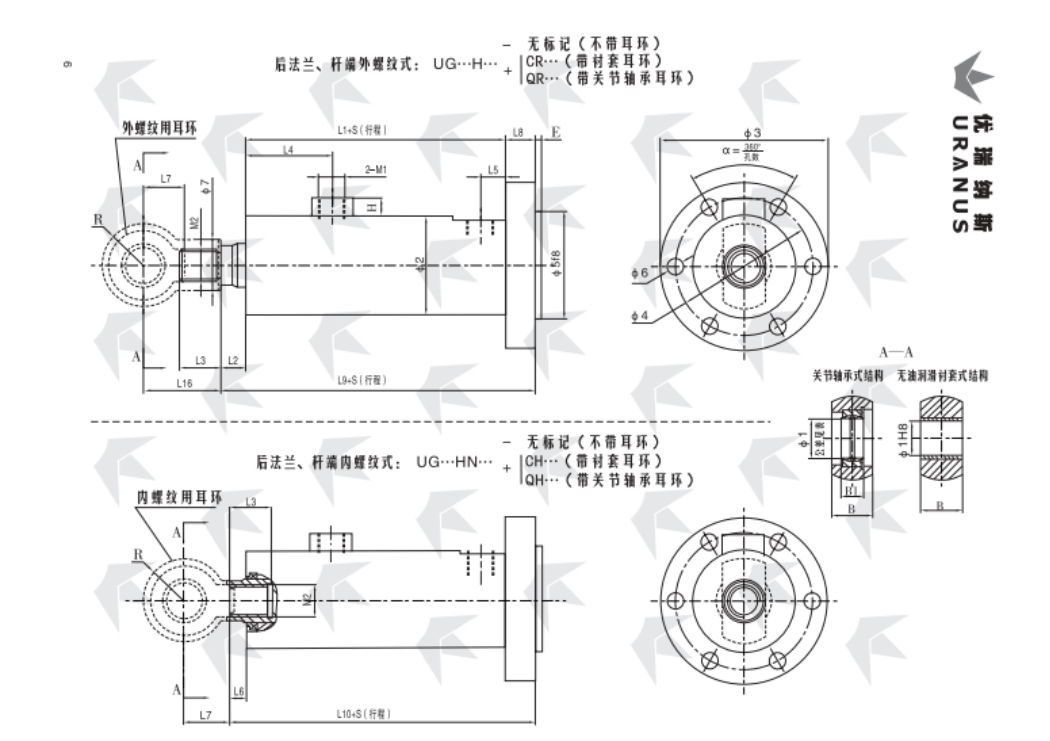

Uri ng hulihan na flange ng UG…H

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 bukas ∅ 11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

203 |

197 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

208 |

200 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 bukas ∅ 13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

25 |

245 |

240 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 mga butas ∅ 13.5 |

42 |

217 |

45 |

75 |

25 |

18 |

55 |

262 |

260 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 mga butas ∅ 15.5 |

48 |

78 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 mga butas ∅ 18 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

30 |

302 |

300 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

257 |

55 |

90 |

90 |

307 |

305 |

135 |

M42×2 |

110-1 |

|||||||||||||||||

63 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 Puwang ∅ 18 |

68 |

267 |

60 |

104 |

87 |

40 |

327 |

325 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 Puwang ∅ 20 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

352 |

350 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 Puwang ∅ 22 |

76 |

297 |

70 |

119 |

110 |

357 |

355 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

302 |

75 |

124 |

115 |

50 |

372 |

370 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 Puwang ∅ 24 |

90 |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

418 |

415 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 Puwang ∅ 26 |

100 |

353 |

95 |

141 |

127 |

100 |

60 |

438 |

435 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 Puwang ∅ 29 |

110 |

393 |

105 |

146 |

143 |

50 |

110 |

70 |

488 |

485 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

|||||||

125 |

120 140 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 bukas ∅ 32 |

120 |

403 |

115 |

155 |

120 |

498 |

495 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

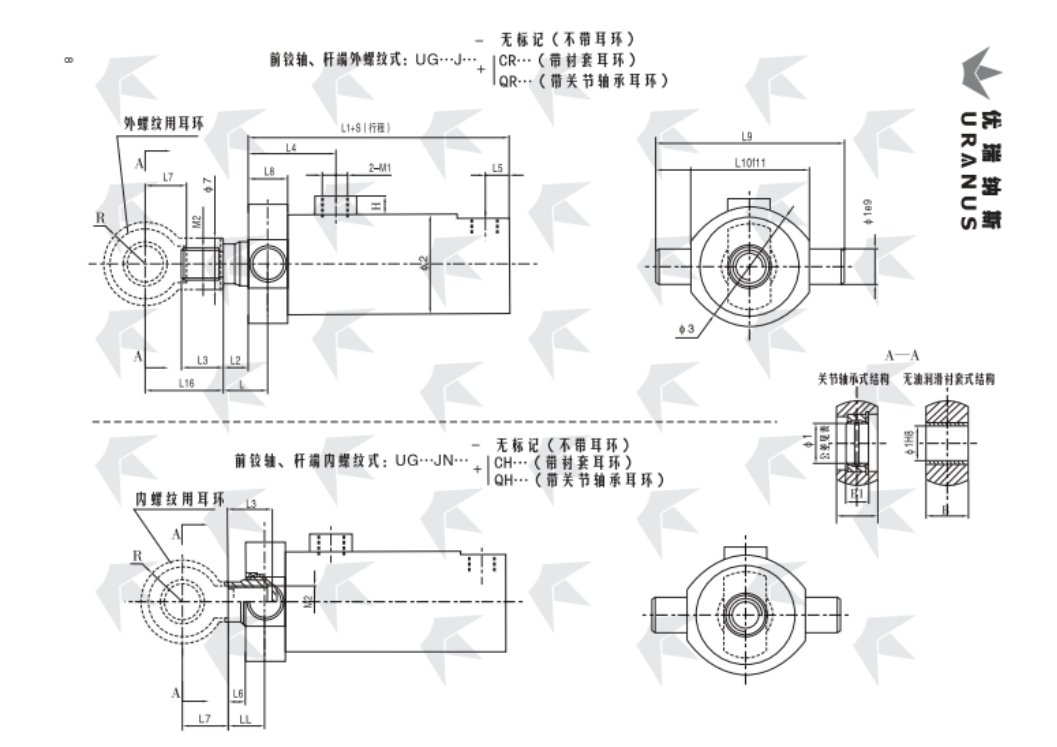

Uri ng harapang shaft ng bisagra ng UG…J

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

30 (24) |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

35 (27) |

170 |

18 |

30 |

58 |

20 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

37 (32) |

200 |

20 |

35 |

73 |

76 |

15 |

155 |

100 |

65 |

J5 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

42 (40) |

217 |

45 |

75 |

25 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

47 (45) |

252 |

50 |

89 |

85 |

30 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

257 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

267 |

60 |

104 |

87 |

35 |

260 |

185 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

52 (50) |

292 |

65 |

114 |

105 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

297 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

302 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

||||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

62 (59) |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

67 (64) |

353 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

72 (65) |

393 |

105 |

146 |

143 |

50 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

355 |

120 |

76 (73) |

403 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||

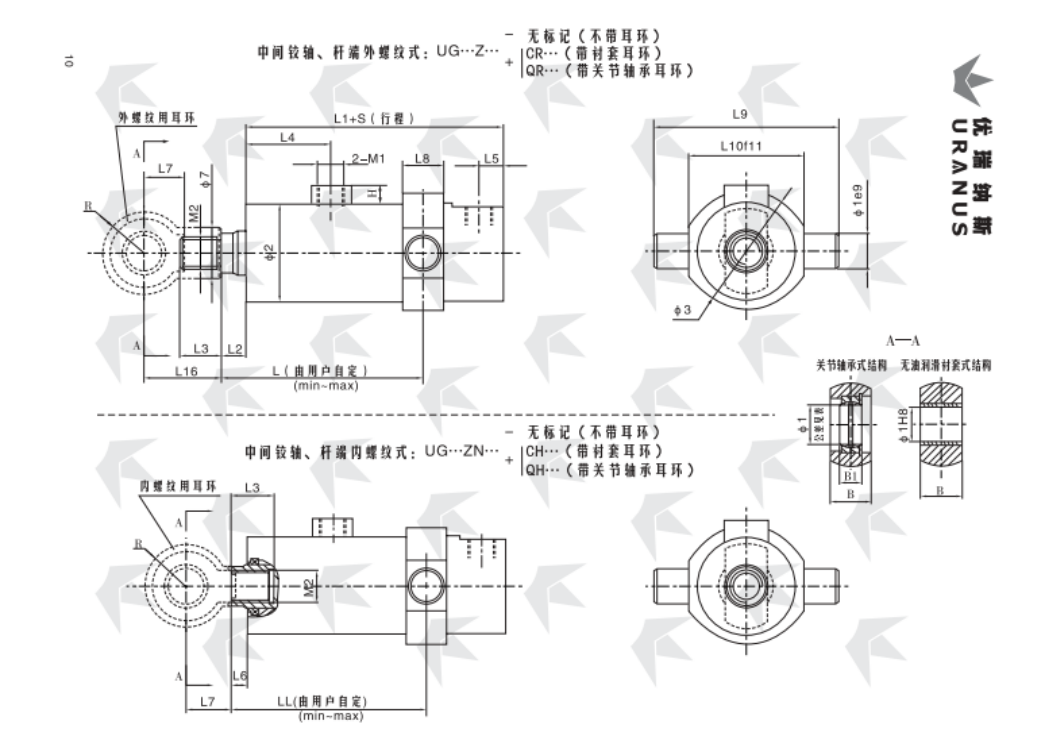

UG…Z uri ng gitnang hinge shaft

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

Mga |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

||||||

Sukat |

Ang toleransya ng butas ng lalagyan |

min |

max |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

|||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

124 (118) |

113+S (107+S) |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

|||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

129 (121) |

112+S (104+S) |

170 |

18 |

30 |

58 |

20 |

15 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

143 (138) |

132+S (127+S) |

200 |

20 |

35 |

73 |

76 |

155 |

100 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

142 (140) |

121+S (139+S) |

217 |

75 |

25 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

|||||||||||

M30 × 2 |

80-1 |

|||||||||||||||||||||||||||||

45 |

48 |

45 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

147 (145) |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

|||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

168 (166) |

149+S (147+S) |

252 |

50 |

89 |

85 |

30 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

169 (167) |

153+S (151+S) |

257 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

|||||||||||||||

63 |

68 |

M48 × 2 |

-2 |

|||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

183 (181) |

158+S (156+S) |

267 |

60 |

104 |

87 |

260 |

185 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

203 (201) |

175+S (173+S) |

292 |

65 |

114 |

105 |

35 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

208 (206) |

177+S (175+S) |

297 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

|||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

213 (211) |

182+S (180+S) |

302 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

233 (230) |

205+S (202+S) |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

250 (247) |

208+S (205+S) |

353 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

262 (259) |

225+S (222+S) |

393 |

105 |

146 |

143 |

50 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

335 |

120 |

275 (272) |

226+S (223+S) |

403 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||

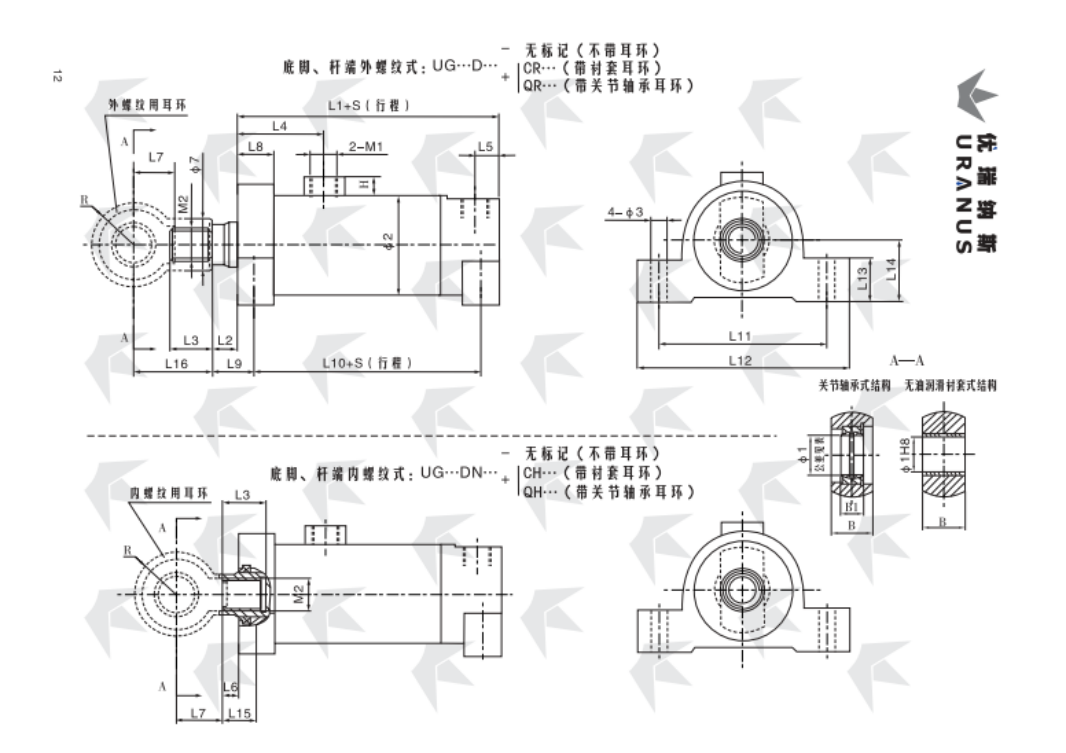

Uri ng paa ng UG…D

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L11 |

L12 |

L13 |

L14 |

L15 |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

||||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

11 |

25 |

167 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

25 |

28.5 |

142 |

105 |

130 |

25 |

40 |

22.5 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

170 |

18 |

30 |

58 |

20 |

40 |

30.5 |

145 |

120 |

150 |

30 |

45 |

22.5 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||||||

63 |

32 |

83 |

13 |

35 |

200 |

20 |

35 |

73 |

76 |

15 |

30 |

35 |

170 |

140 |

175 |

35 |

50 |

30 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

17 |

42 |

217 |

45 |

75 |

25 |

18 |

55 |

40 |

40 |

177 |

160 |

200 |

40 |

60 |

38 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

185 |

230 |

45 |

70 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

||||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

21 |

52 |

252 |

50 |

89 |

85 |

30 |

70 |

45 |

42.5 |

207 |

205 |

255 |

50 |

80 |

40.5 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||||||

110 |

56 |

140 |

60 |

257 |

55 |

90 |

90 |

212 |

230 |

280 |

55 |

90 |

135 |

M42×2 |

110-1 |

||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||||||

125 |

63 |

152 |

25 |

68 |

267 |

60 |

104 |

87 |

55 |

47$ |

255 |

310 |

60 |

100 |

45.5 |

140 |

M48×2 |

125-1 |

|||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

292 |

65 |

114 |

105 |

35 |

80 |

237 |

280 |

340 |

65 |

115 |

155 |

70 |

44 |

M33×2 |

M52×2 |

145-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||||||

150 |

75 |

180 |

76 |

297 |

70 |

119 |

110 |

60 |

50 |

295 |

355 |

67 |

120 |

48 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||||||

160 |

80 |

194 |

31 |

80 |

302 |

75 |

124 |

115 |

65 |

52.5 |

310 |

375 |

70 |

130 |

50.5 |

160 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

343 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

70 |

60 |

273 |

345 |

415 |

75 |

145 |

57 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

|||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

353 |

95 |

141 |

127 |

100 |

283 |

385 |

465 |

80 |

165 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

37 |

110 |

393 |

105 |

146 |

143 |

50 |

110 |

87 |

68.5 |

306 |

435 |

525 |

90 |

185 |

65.5 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

45 |

120 |

403 |

115 |

155 |

120 |

92 |

71 |

311 |

495 |

595 |

100 |

205 |

68 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||||||

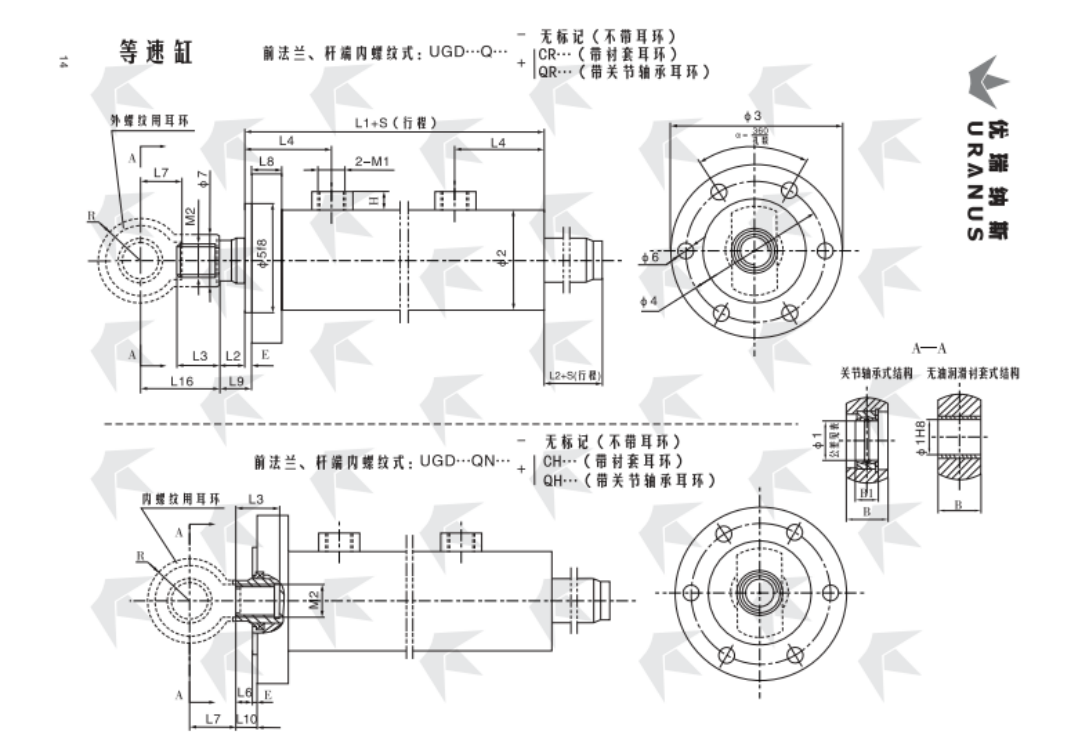

Uri ng harapang manggas ng silindro ng pare-parehong bilis na UGD…D

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅4 |

∅5 f8 |

∅6 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L16 |

E |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

|||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

104 |

84 |

64 |

6 bukas ∅ 11 |

25 |

192 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

20 |

21 |

15 |

50 |

5 |

25 |

16 |

12 |

M18×1.5 |

M14× 1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

|||||||||||||||||||||||||||||

28 |

35 |

M22× 1.5 |

-3 |

|||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

120 |

98 |

76 |

28 |

192 |

18 |

30 |

58 |

20 |

40 |

23 |

60 |

35 |

22 |

M20× 1.5 |

50-1 |

|||||||||||||

28 |

35 |

M22×1.5 |

-2 |

|||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

|||||||||||||||||||||||||||||

63 |

32 |

83 |

140 |

115 |

90 |

6 bukas ∅ 13 |

35 |

232 |

20 |

35 |

73 |

76 |

15 |

25 |

25 |

20 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

|||||||||||

36 |

42 |

M27×2 |

-2 |

|||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

|||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

175 |

145 |

115 |

8 mga butas ∅ 13.5 |

42 |

245 |

45 |

75 |

25 |

18 |

55 |

23 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

|||||||||||

45 |

48 |

M33×2 |

-2 |

|||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

|||||||||||||||||||||||||||||

90 |

45 |

114 |

190 |

160 |

130 |

8 mga butas ∅ 15.5 |

48 |

78 |

110 |

M33×2 |

90-1 |

|||||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

|||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

|||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

210 |

180 |

145 |

8 mga butas ∅ 18 |

52 |

275 |

50 |

89 |

85 |

30 |

70 |

30 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

||||||||||

56 |

60 |

M42×2 |

-2 |

|||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

|||||||||||||||||||||||||||||

110 |

56 |

140 |

225 |

195 |

160 |

60 |

285 |

55 |

90 |

90 |

135 |

M42×2 |

110-1 |

|||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

|||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

|||||||||||||||||||||||||||||

125 |

63 |

152 |

240 |

210 |

175 |

10 Puwang ∅ 18 |

68 |

298 |

60 |

104 |

87 |

40 |

140 |

M48×2 |

125-1 |

|||||||||||||||||

70 |

72 |

M52×2 |

-2 |

|||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

|||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

260 |

225 |

190 |

10 Puwang ∅ 20 |

72 |

328 |

65 |

114 |

105 |

35 |

80 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

|||||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

285 |

245 |

205 |

10 Puwang ∅ 22 |

76 |

333 |

70 |

119 |

110 |

157 |

M56×2 |

150-1 |

||||||||||||||||||

85 |

85 |

M64×2 |

-2 |

|||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

|||||||||||||||||||||||||||||

160 |

80 |

194 |

300 |

260 |

220 |

80 |

343 |

75 |

124 |

115 |

50 |

30 |

28 |

160 |

10 |

M60×2 |

160-1 |

|||||||||||||||

90 |

90 |

M68×2 |

-2 |

|||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

|||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

325 |

285 |

245 |

10 Puwang ∅ 24 |

90 |

376 |

|

85 |

129 |

122 |

40 |

|

90 |

35 |

32 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||||

100 |

100 |

M76×3 |

-2 |

|||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

|||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

365 |

320 |

275 |

10 Puwang ∅ 26 |

100 |

396 |

95 |

141 |

127 |

100 |

60 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||||||

110 |

110 |

M85×3 |

-2 |

|||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

|||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

405 |

355 |

305 |

10 Puwang ∅ 29 |

110 |

436 |

|

105 |

146 |

143 |

50 |

|

110 |

70 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

|||||||

125 |

120 |

M95×3 |

-2 |

|||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

|||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

450 |

390 |

330 |

12 bukas ∅ 32 |

120 |

446 |

115 |

155 |

120 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||||||

140 |

125 |

M100×3 |

-2 |

|||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

|||||||||||||||||||||||||||||

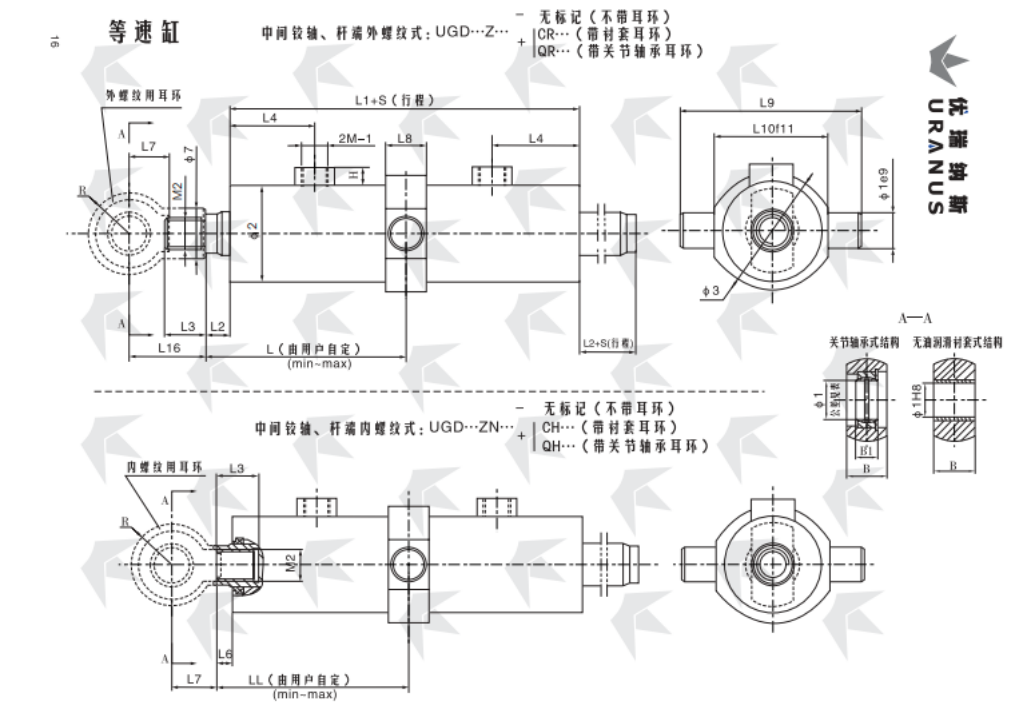

Uri ng gitnang hinge shaft na UGD…Z na silindro ng pare-pareho ang bilis

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅7 |

L (LL) |

L1 |

L2 |

L3 |

L4 |

L6 |

L7 |

L8 |

L9 |

L10 (f11) |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

||||||

Sukat |

Ang toleransya ng butas ng lalagyan |

min |

max |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

70 |

25 |

124 (118) |

100+S (94+S) |

192 |

16 |

25 |

70 |

59 |

10 |

30 |

28 |

110 |

70 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

80 |

28 |

129 (121) |

99+S (91+S) |

192 |

18 |

30 |

58 |

40 |

34 |

130 |

80 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||

63 |

32 |

83 |

100 |

35 |

143 (138) |

129+S (124+S) |

232 |

20 |

35 |

73 |

76 |

15 |

155 |

100 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

120 |

42 |

142 (140) |

143+S (141+S) |

245 |

45 |

75 |

18 |

55 |

44 |

185 |

125 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||

90 |

45 |

114 |

135 |

48 |

147 (145) |

138+S (136+S) |

78 |

200 |

140 |

110 |

M33×2 |

90-1 |

|||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

150 |

52 |

168 (166) |

147+S (145+S) |

275 |

50 |

89 |

85 |

70 |

54 |

230 |

155 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||

110 |

56 |

140 |

165 |

60 |

169 (167) |

156+S (154+S) |

285 |

55 |

90 |

90 |

245 |

170 |

135 |

M42×2 |

110-1 |

||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||

125 |

63 |

152 |

185 |

68 |

183 (181) |

155+S (153+S) |

298 |

60 |

104 |

87 |

260 |

185 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

210 |

72 |

203 (201) |

165+S (163+S) |

328 |

65 |

114 |

105 |

80 |

64 |

290 |

200 |

155 |

70 |

44 |

M33×2 |

M52×2 |

140-1 |

|||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||

100 |

100 |

M76×3 |

-3 |

||||||||||||||||||||||||||

150 |

75 |

180 |

222 |

76 |

208 (206) |

165+S (163+S) |

333 |

70 |

119 |

110 |

305 |

215 |

157 |

M56×2 |

150-1 |

||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||

160 |

80 |

194 |

235 |

80 |

213 (211) |

170+S (168+S) |

343 |

75 |

124 |

115 |

320 |

230 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

270 |

90 |

233 (230) |

193+S (190+S) |

376 |

25 |

85 |

129 |

122 |

22 |

90 |

74 |

360 |

255 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

295 |

100 |

250 (247) |

196+S (193+S) |

396 |

95 |

141 |

127 |

100 |

84 |

405 |

285 |

200 |

90 |

55 |

M76×3 |

200-1 |

|||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

330 |

110 |

262 (259) |

224+S (221+S) |

436 |

105 |

146 |

143 |

110 |

94 |

455 |

320 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

335 |

120 |

275 (272) |

221+S (218+S) |

446 |

115 |

155 |

120 |

102 |

500 |

350 |

245 |

110 |

70 |

M95×3 |

250-1 |

||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||

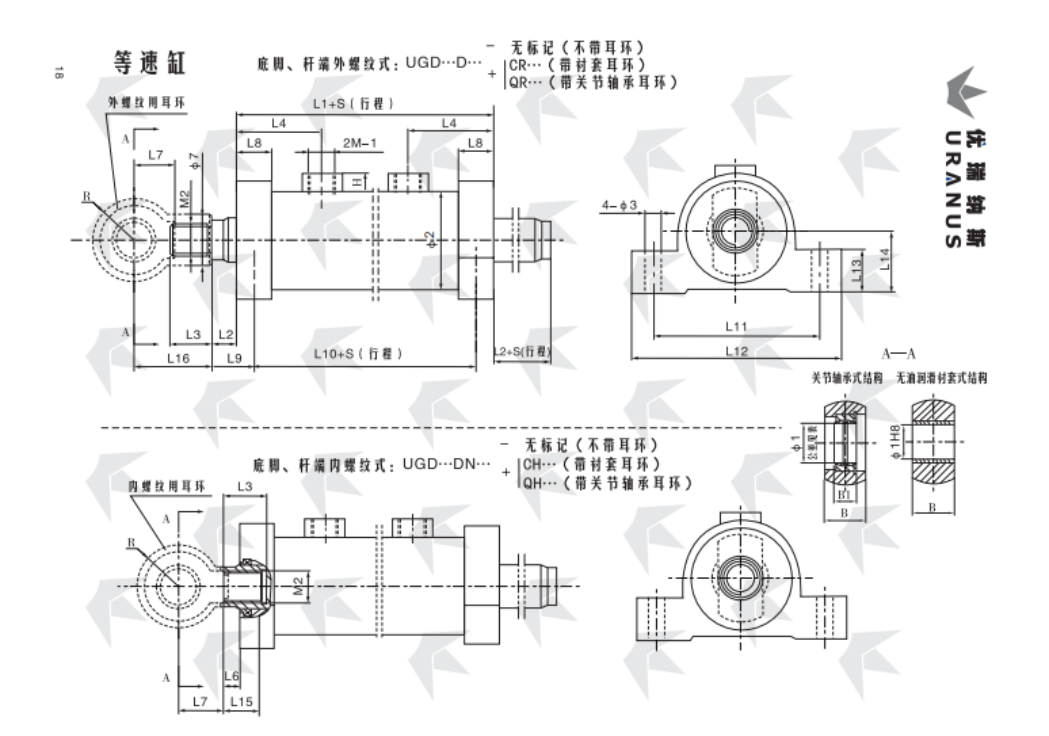

UGD…D uri ng paa na pare-pareho ang bilis ng silindro

Dyametro ng Silinder |

Diyametro ng rod |

∅1 |

∅2 |

∅3 |

∅7 |

L1 |

L2 |

L3 |

L4 |

L5 |

L6 |

L7 |

L8 |

L9 |

L10 |

L11 |

L12 |

L13 |

L14 |

L15 |

L16 |

R |

B |

B1 |

H |

M1 |

M2 |

Ang tungkol ng tungkod ng ari-arian |

|||||

Sukat |

Ang toleransya ng butas ng lalagyan |

Hindi-kuskus |

Pampulyo Y |

CR |

QR |

Ch |

QH |

||||||||||||||||||||||||||

40 |

20 |

20 |

0-0.010 |

58 |

11 |

25 |

192 |

16 |

25 |

70 |

59 |

17 |

10 |

30 |

25 |

28.5 |

167 |

105 |

130 |

25 |

40 |

22.5 |

50 |

25 |

16 |

12 |

M18×1.5 |

M14×1.5 |

40-1 |

||||

22 |

28 |

M16×1.5 |

-2 |

||||||||||||||||||||||||||||||

28 |

35 |

M22×1.5 |

-3 |

||||||||||||||||||||||||||||||

50 |

25 |

30 |

70 |

28 |

192 |

18 |

30 |

58 |

20 |

40 |

30.5 |

167 |

120 |

150 |

30 |

45 |

22.5 |

60 |

35 |

22 |

M20×1.5 |

50-1 |

|||||||||||

28 |

35 |

M22×1.5 |

-2 |

||||||||||||||||||||||||||||||

36 |

42 |

M27×2 |

-3 |

||||||||||||||||||||||||||||||

63 |

32 |

83 |

13 |

35 |

232 |

20 |

35 |

73 |

76 |

15 |

30 |

35 |

202 |

140 |

175 |

35 |

50 |

30 |

65 |

15 |

M22×1.5 |

M24×1.5 |

63-1 |

||||||||||

36 |

42 |

M27×2 |

-2 |

||||||||||||||||||||||||||||||

45 |

45 |

M33×2 |

-3 |

||||||||||||||||||||||||||||||

80 |

40 |

40 |

0-0.012 |

108 |

17 |

42 |

245 |

45 |

75 |

25 |

18 |

55 |

40 |

40 |

205 |

160 |

200 |

40 |

60 |

38 |

105 |

45 |

28 |

M30 × 2 |

80-1 |

||||||||

45 |

48 |

M33×2 |

-2 |

||||||||||||||||||||||||||||||

56 |

60 |

M42×2 |

-3 |

||||||||||||||||||||||||||||||

90 |

45 |

114 |

48 |

78 |

185 |

230 |

45 |

70 |

110 |

M33×2 |

90-1 |

||||||||||||||||||||||

50 |

52 |

M36 × 2 |

-2 |

||||||||||||||||||||||||||||||

63 |

68 |

M48×2 |

-3 |

||||||||||||||||||||||||||||||

100 |

50 |

50 |

127 |

21 |

52 |

275 |

50 |

89 |

85 |

30 |

70 |

45 |

42.5 |

230 |

205 |

255 |

50 |

80 |

40.5 |

130 |

60 |

35 |

20 |

M27×2 |

M36 × 2 |

100-1 |

|||||||

56 |

60 |

M42×2 |

-2 |

||||||||||||||||||||||||||||||

70 |

72 |

M52×2 |

-3 |

||||||||||||||||||||||||||||||

110 |

56 |

140 |

60 |

285 |

55 |

90 |

90 |

240 |

230 |

280 |

55 |

90 |

135 |

M42×2 |

110-1 |

||||||||||||||||||

63 |

68 |

M48×2 |

-2 |

||||||||||||||||||||||||||||||

80 |

80 |

M60×2 |

-3 |

||||||||||||||||||||||||||||||

125 |

63 |

152 |

25 |

68 |

298 |

60 |

104 |

87 |

55 |

47.5 |

243 |

255 |

310 |

60 |

100 |

45.5 |

140 |

M48×2 |

125-1 |

||||||||||||||

70 |

72 |

M52×2 |

-2 |

||||||||||||||||||||||||||||||

90 |

90 |

M68×2 |

-3 |

||||||||||||||||||||||||||||||

140 |

70 |

60 |

0-0.015 |

168 |

72 |

328 |

65 |

114 |

105 |

35 |

80 |

273 |

280 |

340 |

65 |

115 |

155 |

70 |

44 |

|

M52×2 |

145-1 |

|||||||||||

80 |

80 |

M60×2 |

-2 |

||||||||||||||||||||||||||||||

100 |

100 |

M33×2 |

M76×3 |

-3 |

|||||||||||||||||||||||||||||

150 |

75 |

180 |

76 |

333 |

70 |

119 |

110 |

60 |

50 |

295 |

355 |

67 |

120 |

48 |

157 |

M56×2 |

150-1 |

||||||||||||||||

85 |

85 |

M64×2 |

-2 |

||||||||||||||||||||||||||||||

105 |

105 |

M80×3 |

-3 |

||||||||||||||||||||||||||||||

160 |

80 |

194 |

31 |

80 |

343 |

75 |

124 |

115 |

65 |

52.5 |

278 |

310 |

375 |

70 |

130 |

50.5 |

160 |

M60×2 |

160-1 |

||||||||||||||

90 |

90 |

M68×2 |

-2 |

||||||||||||||||||||||||||||||

110 |

110 |

M85×3 |

-3 |

||||||||||||||||||||||||||||||

180 |

90 |

70 |

219 |

90 |

376 |

25 |

85 |

129 |

122 |

40 |

22 |

90 |

70 |

60 |

306 |

345 |

415 |

75 |

145 |

57 |

180 |

80 |

49 |

M42×2 |

M68×2 |

180-1 |

|||||||

100 |

100 |

M76×3 |

-2 |

||||||||||||||||||||||||||||||

125 |

120 |

M95×3 |

-3 |

||||||||||||||||||||||||||||||

200 |

100 |

80 |

245 |

100 |

396 |

95 |

141 |

127 |

100 |

326 |

385 |

465 |

80 |

165 |

200 |

90 |

55 |

M76×3 |

200-1 |

||||||||||||||

110 |

110 |

M85×3 |

-2 |

||||||||||||||||||||||||||||||

140 |

125 |

M100×3 |

-3 |

||||||||||||||||||||||||||||||

220 |

110 |

90 |

0-0.020 |

272 |

37 |

110 |

436 |

105 |

146 |

143 |

50 |

110 |

87 |

68.5 |

349 |

435 |

525 |

90 |

185 |

65.5 |

225 |

100 |

60 |

25 |

M48×2 |

M85×3 |

220-1 |

||||||

125 |

120 |

M95×3 |

-2 |

||||||||||||||||||||||||||||||

160 |

140 |

M125×3 |

-3 |

||||||||||||||||||||||||||||||

250 |

125 |

100 |

299 |

45 |

120 |

446 |

115 |

155 |

120 |

92 |

71 |

354 |

495 |

595 |

100 |

205 |

68 |

245 |

110 |

70 |

M95×3 |

250-1 |

|||||||||||

140 |

125 |

M100×3 |

-2 |

||||||||||||||||||||||||||||||

180 |

160 |

M145×3 |

-3 |

||||||||||||||||||||||||||||||