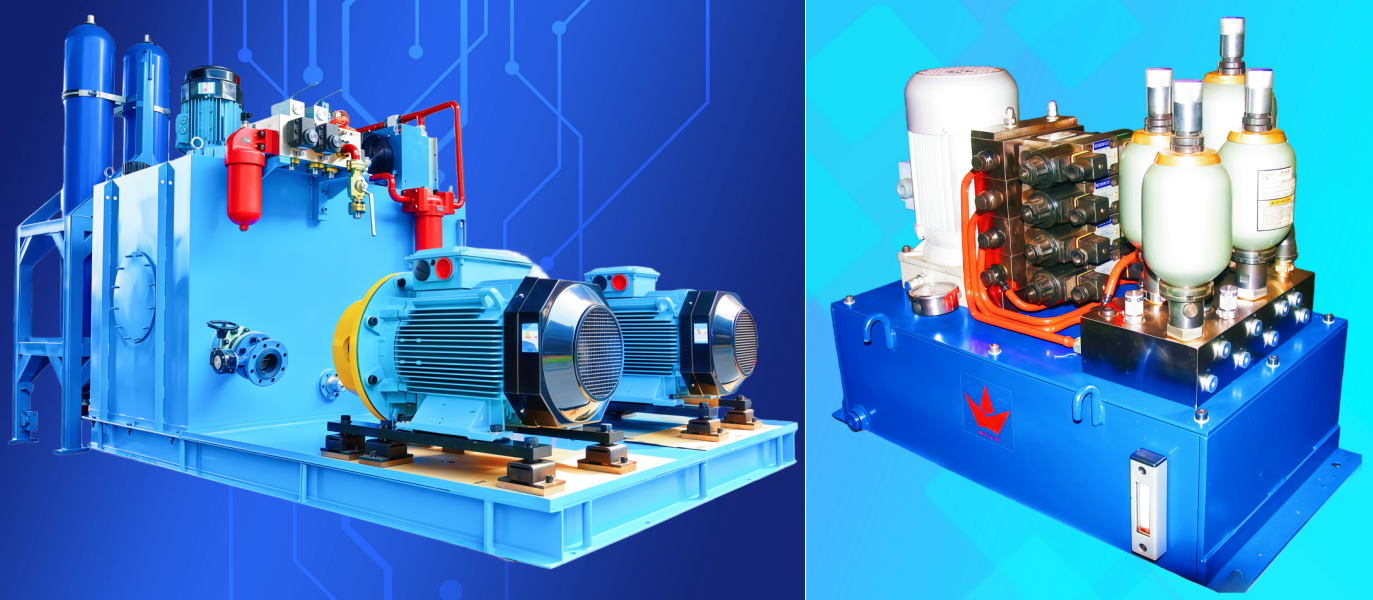

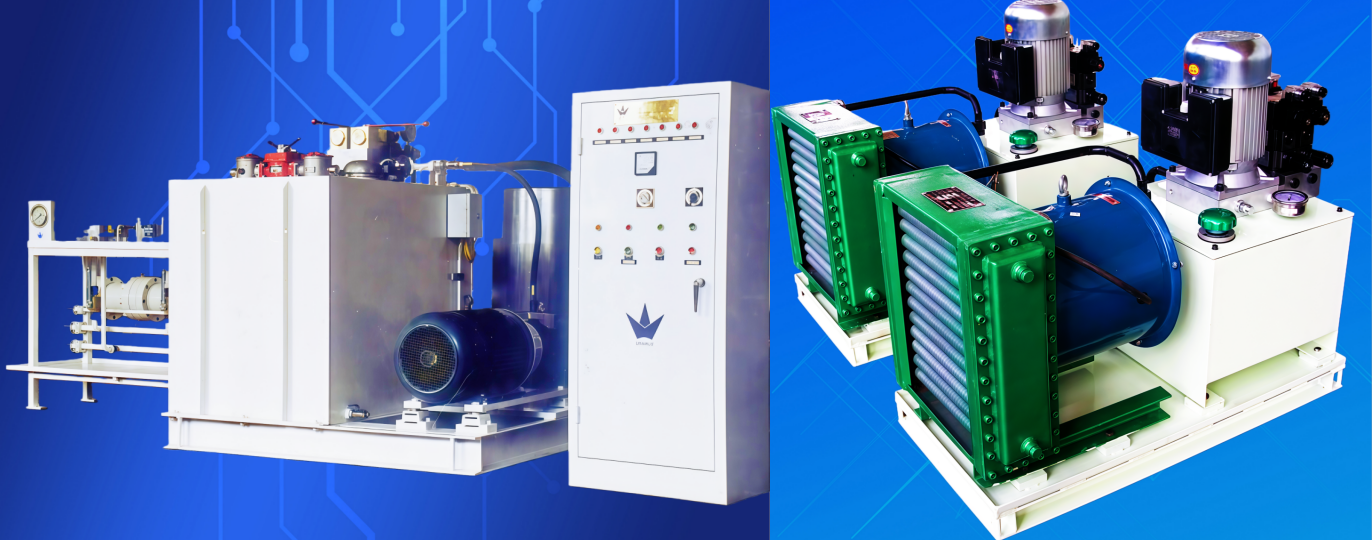

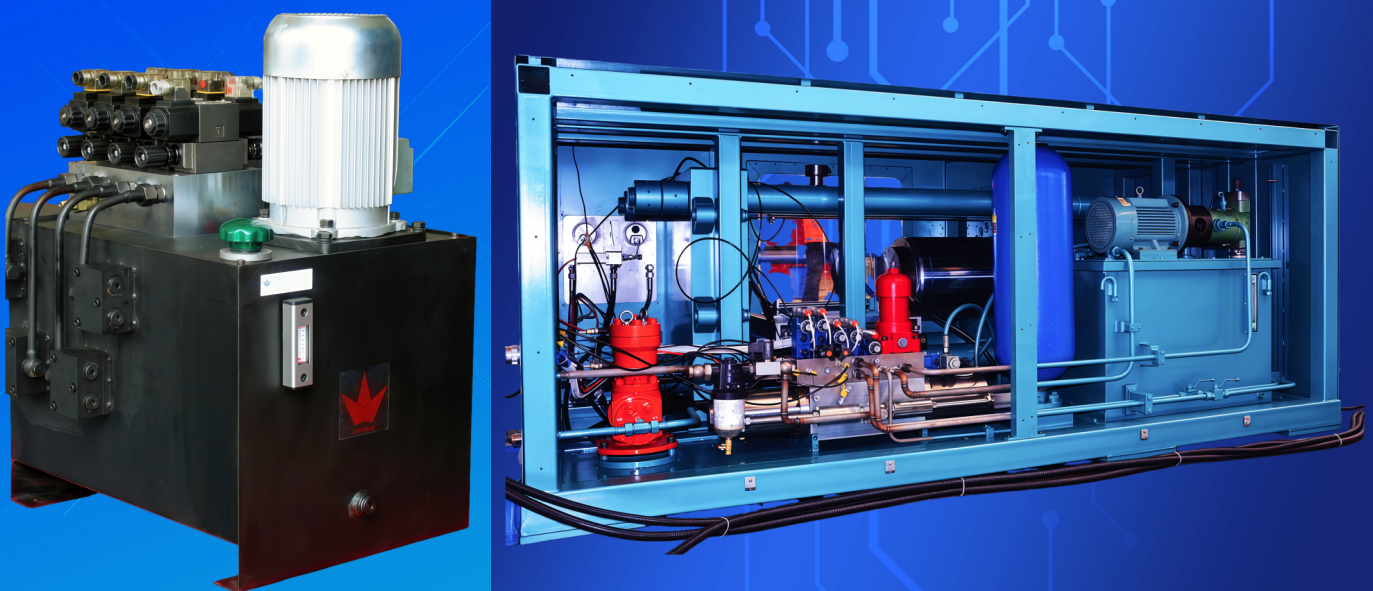

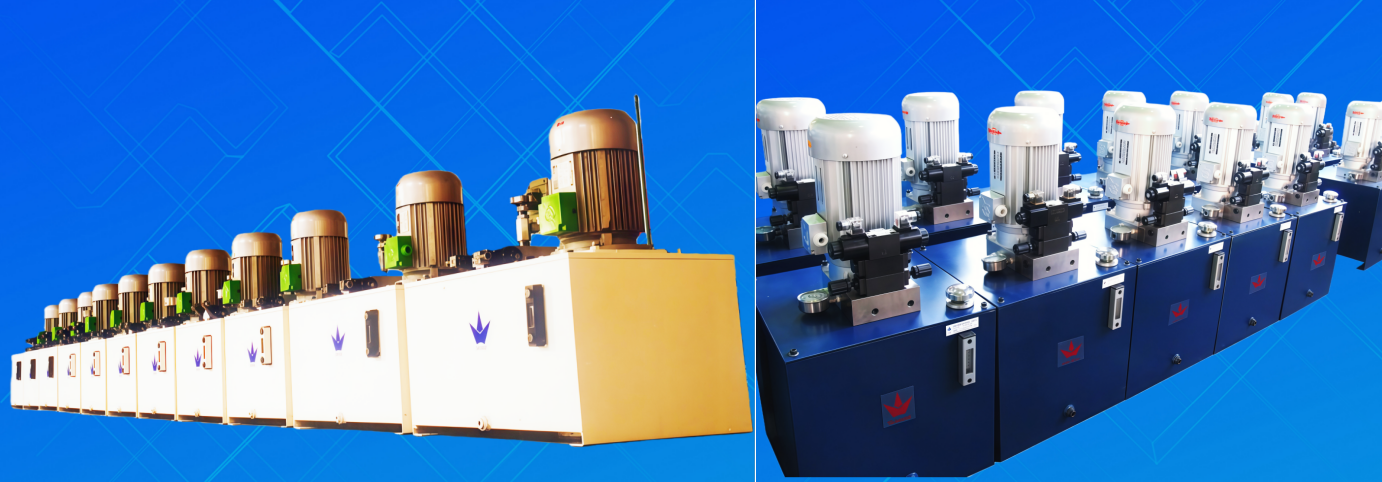

Customized hydraulic station pictures

Customized Hydraulic Power Unit Solutions

We are a specialized manufacturer of hydraulic cylinders and hydraulic power units (HPUs), dedicated to delivering high-performance, fully customized hydraulic solutions tailored to meet diverse and demanding industrial applications.

Our customization process begins with in-depth communication. Our engineering team carefully analyzes your requirements, including operating environment, duty cycle, technical specifications, precision needs, and installation constraints. Whether it’s for heavy-duty machinery or high-precision automated production lines, we design the optimal hydraulic power unit to match your application.

With the support of experienced engineers and advanced design software, we meticulously handle every aspect of the design process—pump station layout, piping routing, component selection, and system optimization—backed by simulation and validation to guarantee excellent performance, fast response, and reliable operation.

In production, we source globally recognized hydraulic components, high-performance seals, and premium-grade metal materials to minimize leakage risks and significantly extend equipment lifespan. Our CNC machining, precision welding, ultrasonic cleaning, strict assembly, and comprehensive testing procedures ensure that every HPU we deliver meets the highest quality standards.

Beyond performance, our HPUs are fully adaptable in appearance and size to integrate seamlessly with your equipment. We offer a variety of paint finishes, protection classes, and mounting configurations to withstand challenging and harsh operating conditions.

Additionally, we provide comprehensive after-sales and technical support. Should any issue arise during operation, our support team responds promptly with solutions. For large or complex HPUs, we offer on-site commissioning, operator training, and maintenance guidance, ensuring your system runs efficiently and reliably for years to come.

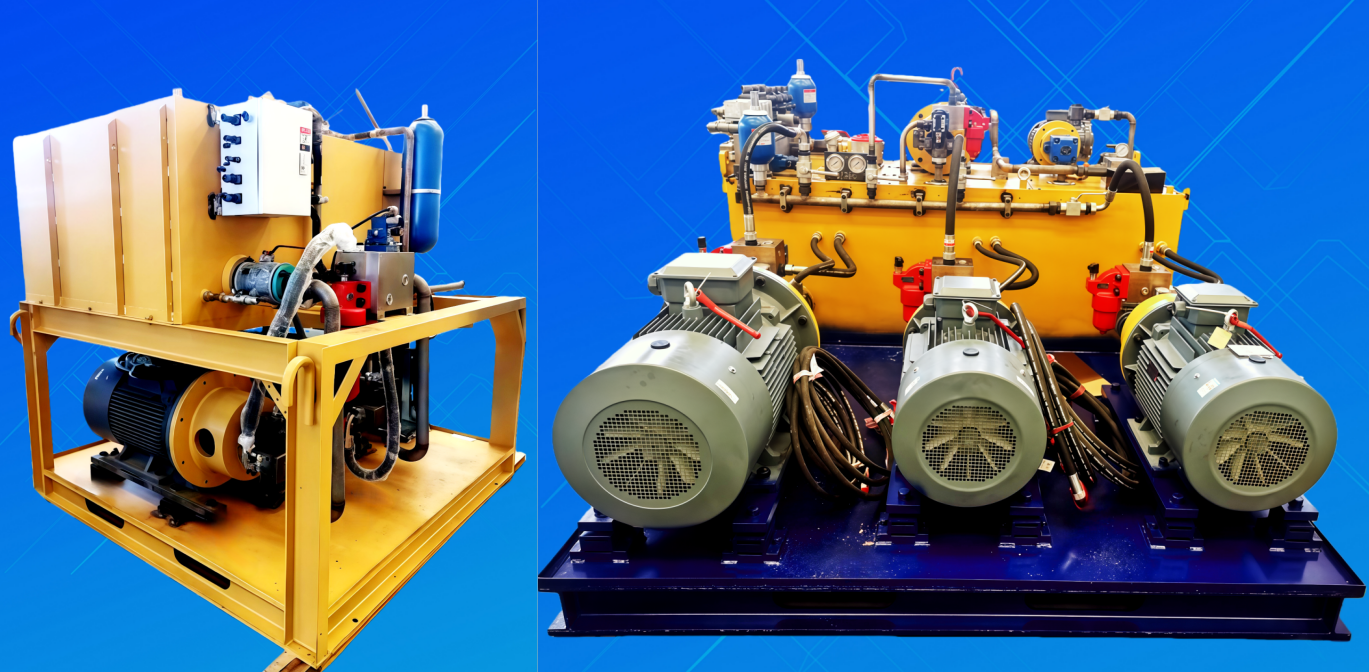

Example of customized hydraulic station:

1. submersible motors Intelligent assembly machine hydraulic station

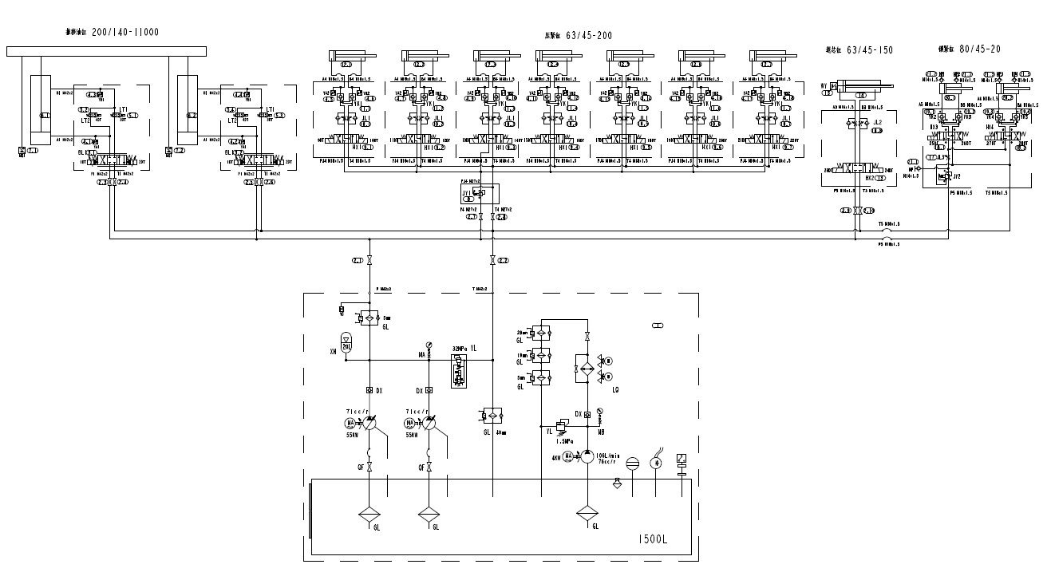

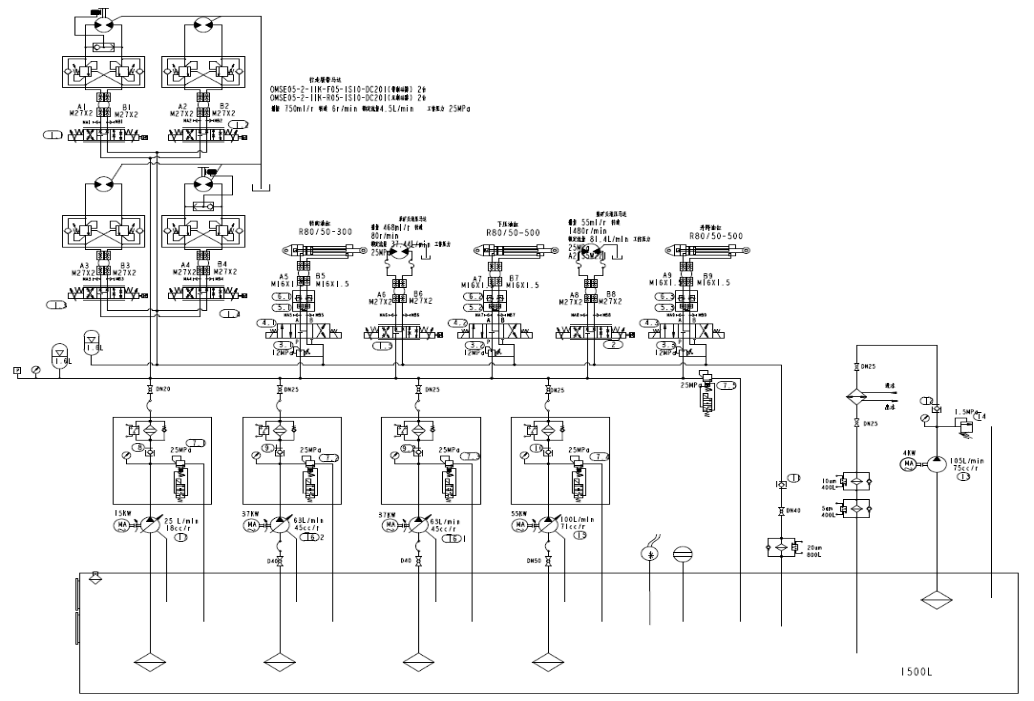

Main system technical parameters

Rated system pressure: 32MPa, rated flow rate: 200L/min, motor power: 2X55KW, oil tank capacity: 1500L

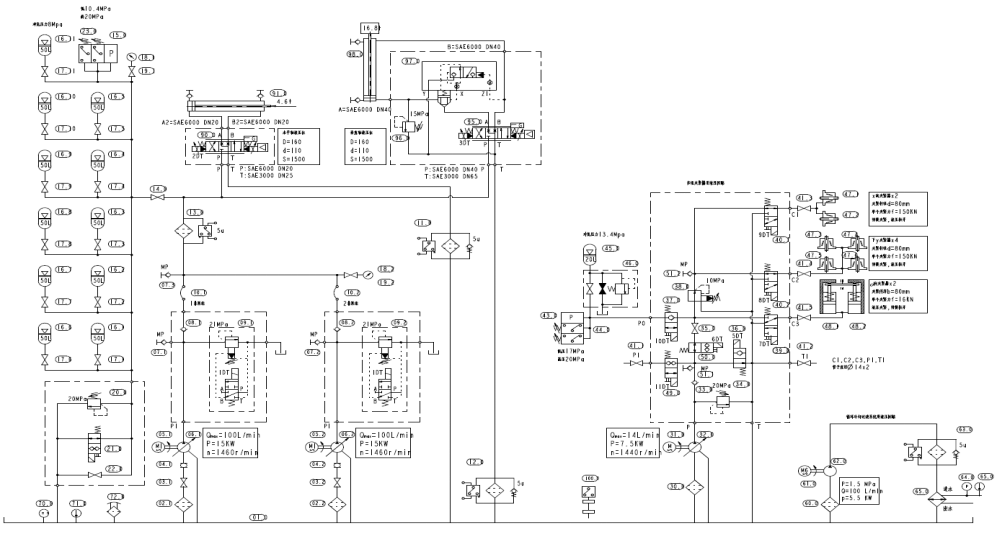

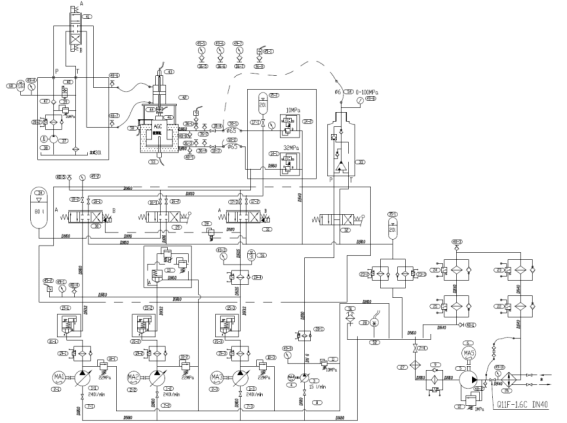

hydraulic schematic diagram

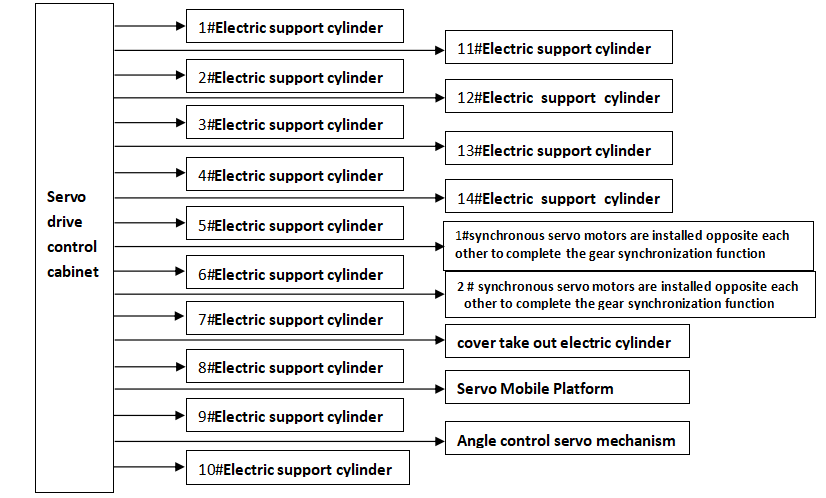

Servo drive control electrical block diagram

explain:

1. Total number of servo motors: 19 units

2.1 #~14 # servo electric cylinders are installed vertically, with braking function and hard limit protection

3.1 # and 2 # synchronous servo motors are installed opposite each other to complete the gear synchronization function

4. Install the cover take out electric cylinder horizontally without braking function, with hard limit protection

5. The servo mobile platform is installed horizontally and has 2 hard limit positions,

6. Horizontal installation of angle control servo cylinder, setting torque protection and soft limit

2. Deep sea cable trench excavation and laying hydraulic station

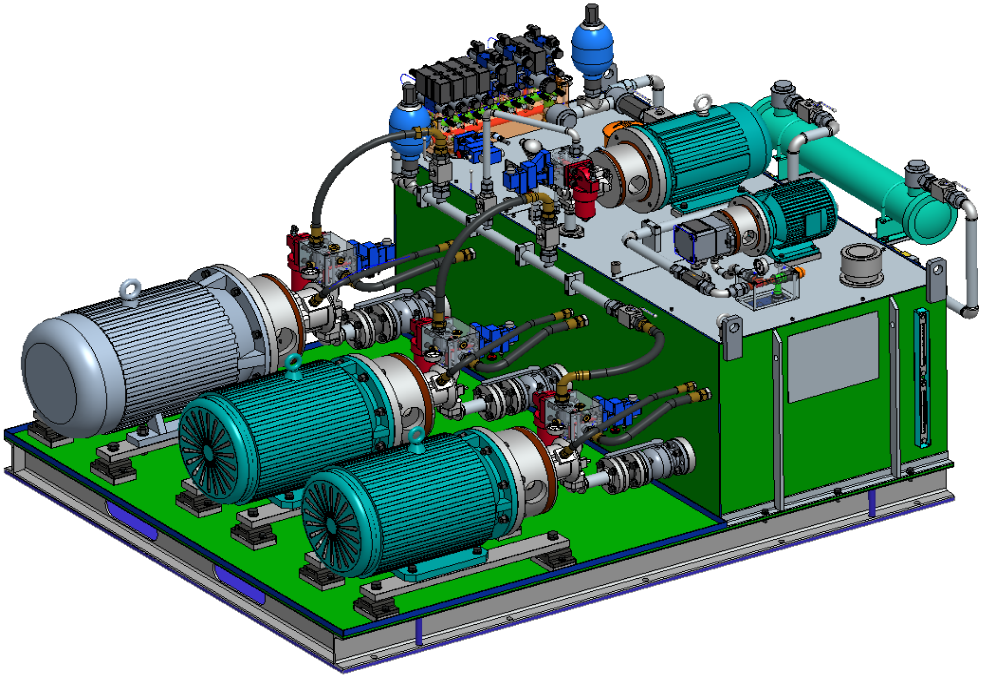

Main system technical parameters

Rated system pressure: 25MPa, rated flow rate: 250L/min, motor power: 150KW, oil tank capacity: 1500L

hydraulic schematic diagram

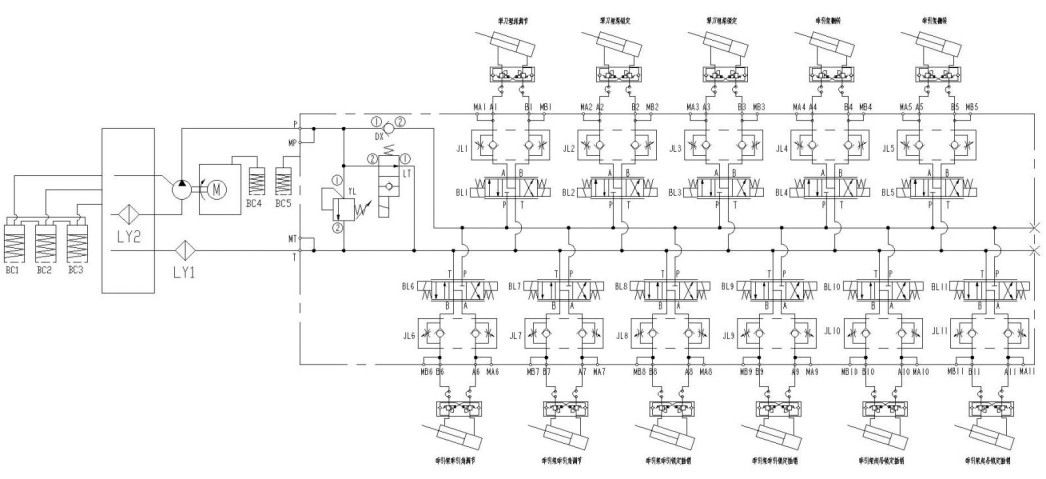

3. Deep sea cable laying hydraulic station

Main system technical parameters

Rated system pressure: 16MPa, rated flow rate: 40L/min, motor power: 15KW, oil tank capacity: 25L

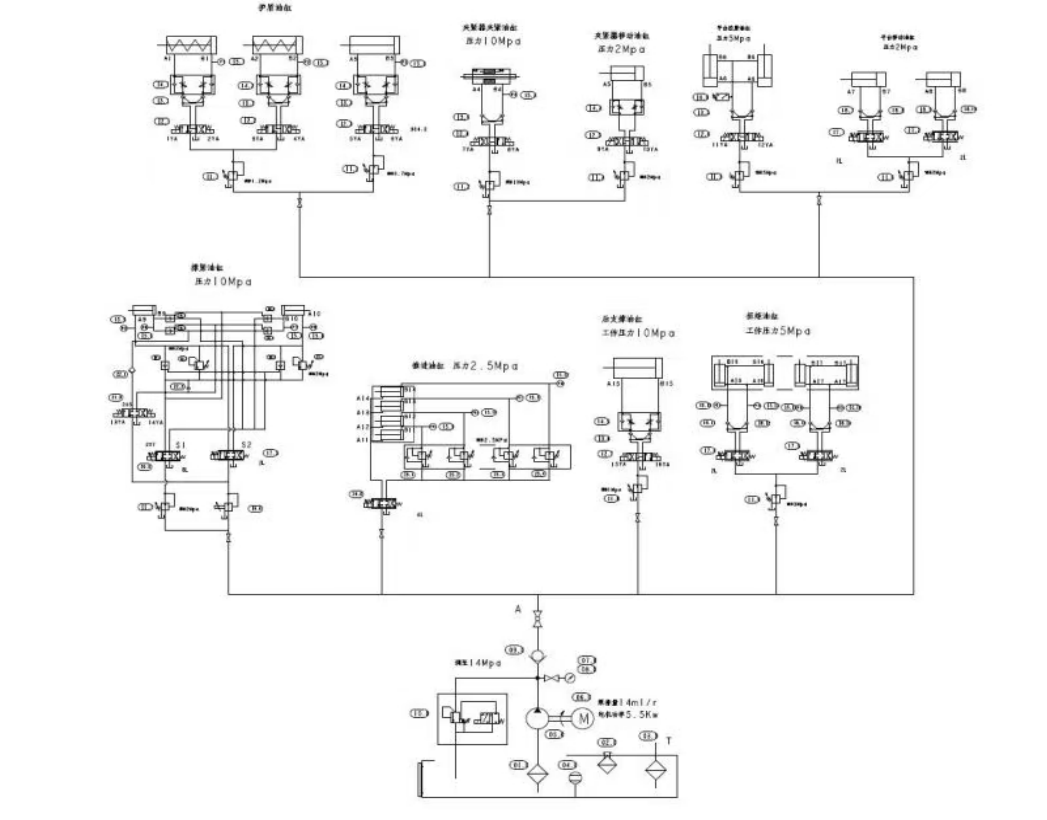

hydraulic schematic diagram

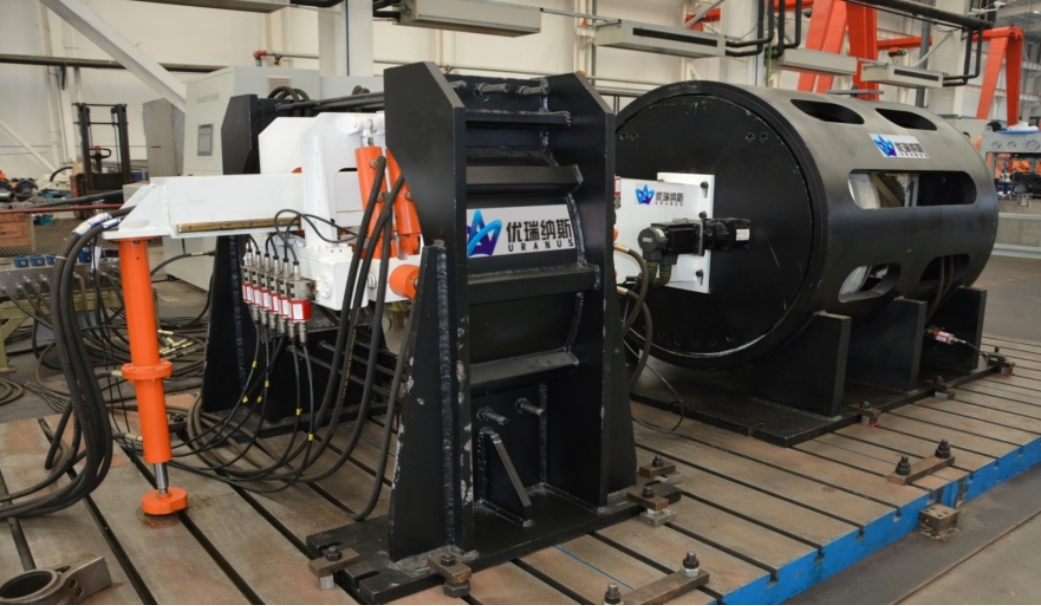

4. Hydraulic station of hard rock excavation machine prototype

Main system technical parameters

Rated system pressure: 14MPa, test pressure: 16MPa, rated flow rate: 21/min, motor power: 5.5KW, oil tank capacity: 200L. Hydraulic schematic diagram:

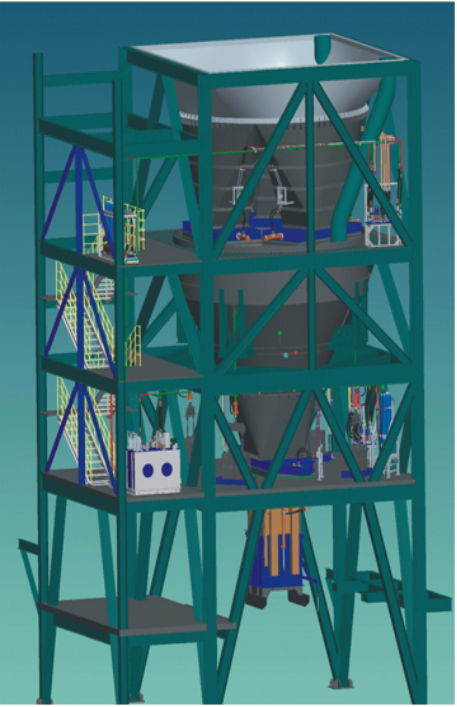

5. Intelligent bulk material rapid quantitative loading station

Main system technical parameters

Rated system pressure: 15MPa, test pressure: 16MPa, rated flow rate: 21L/min, motor power: 2X55KW, oil tank capacity: 1400L

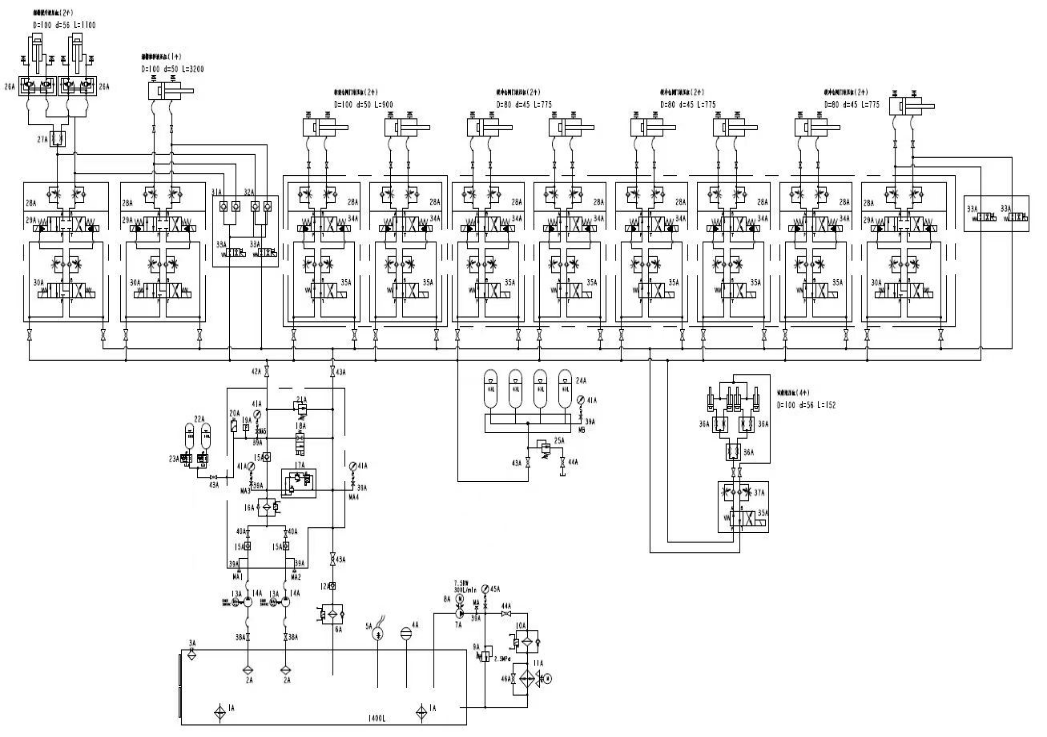

hydraulic schematic diagram:

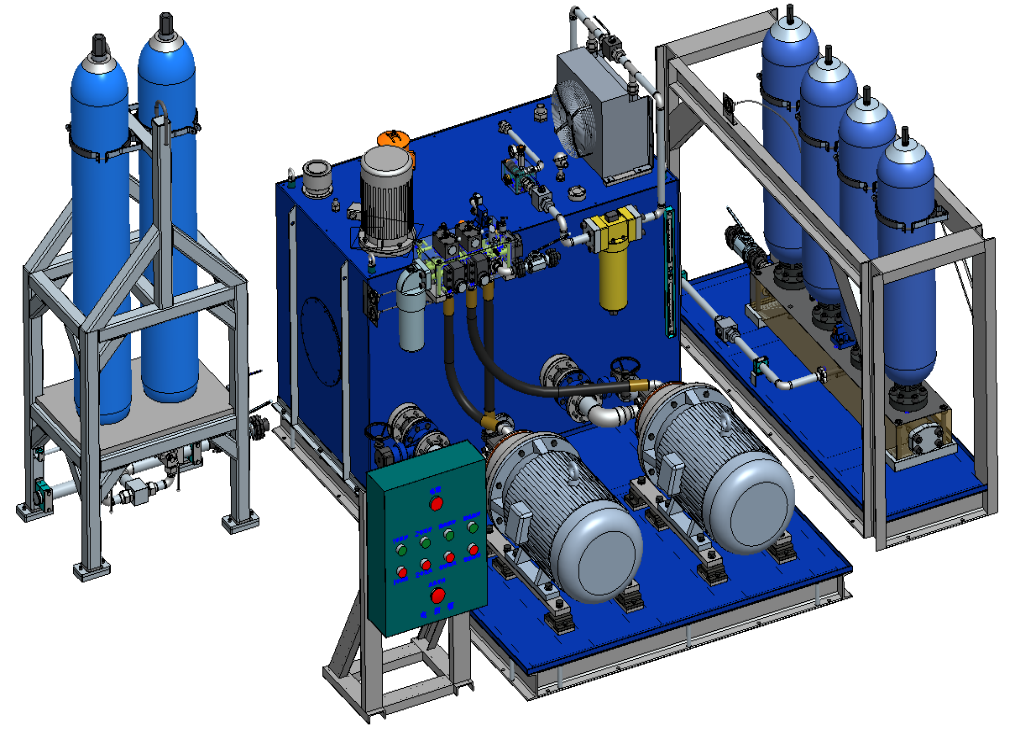

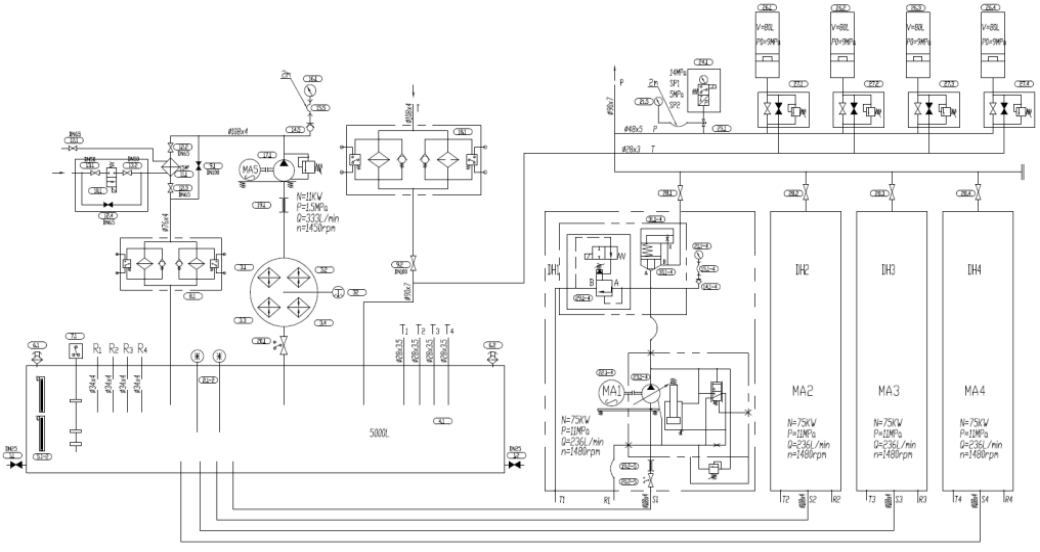

6. Rail beam rolling hydraulic station

Main system technical parameters

Rated system pressure: 11MPa, test pressure: 14MPa, rated flow rate: 708L/min, motor power: 4X75KW, oil tank capacity: 5000L.

Hydraulic schematic diagram:

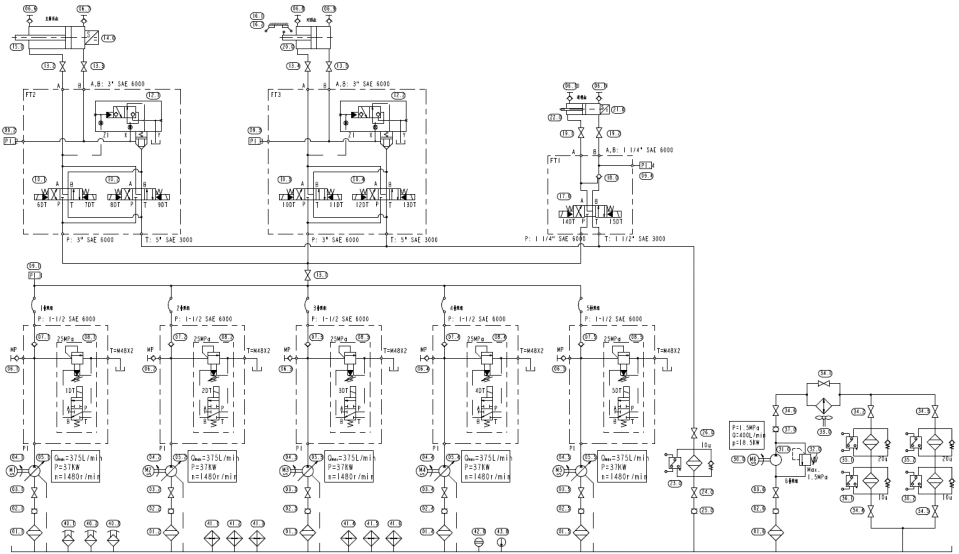

7. Garbage extruder hydraulic station

Main system technical parameters

Rated system pressure: 25MPa, test pressure: 35MPa, rated flow rate 1875L/min, motor power 5X37KW, oil tank capacity: 8000L

hydraulic schematic diagram

ydraulic station pictures

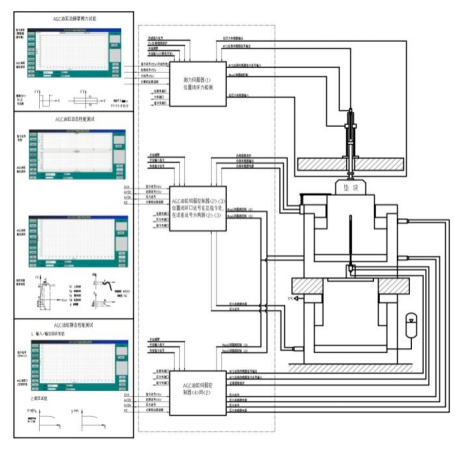

8. 80000KN rolling mill AGC servo hydraulic cylinder test bench hydraulic station

Technical parameters of the main system

Rated system pressure: 25MPa, test pressure: 35MPa/100MPa, rated flow rate: 1500L/min, motor power: 3X110KW, oil tank volume: 5000L. The system can achieve static and dynamic testing of servo hydraulic cylinders, with dynamic testing frequency up to 1000HZ. It can print current, pressure, friction, displacement, frequency and comprehensive waveform diagrams, as well as print friction loop, time domain characteristics and amplitude frequency characteristics curves of AGC servo hydraulic cylinders.

Hydraulic schematic diagramElectrical Schematic diagram

Photo of hydraulic station

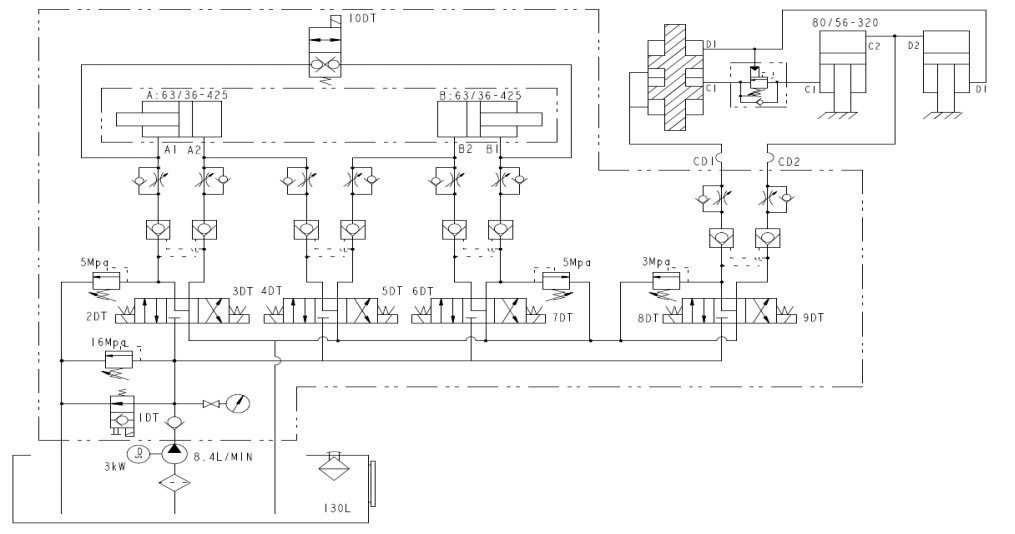

9. Unwinding unit hydraulic station

Main system technical parameters

Rated system pressure: 16MPa, rated flow rate: 8.4L/min, motor power: 3KW, oil tank capacity: 130L

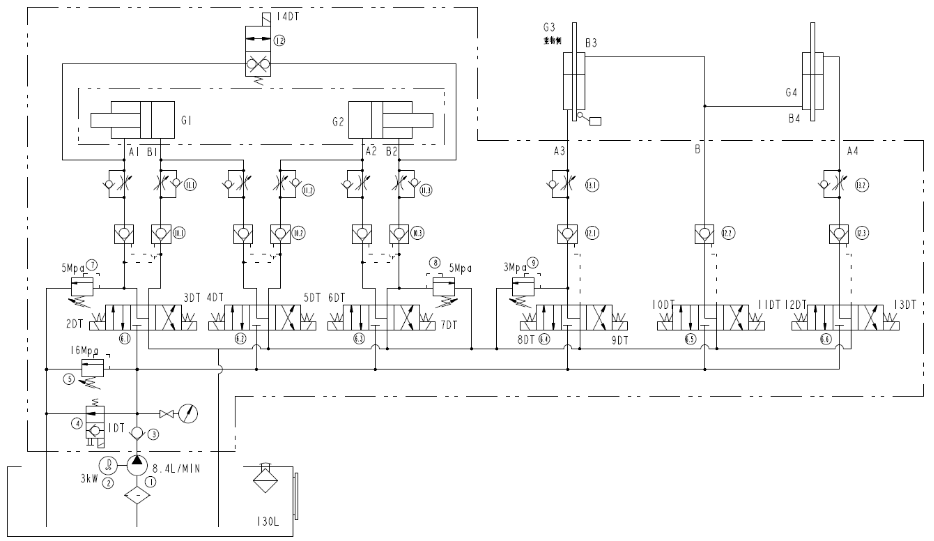

Hydraulic schematic diagram

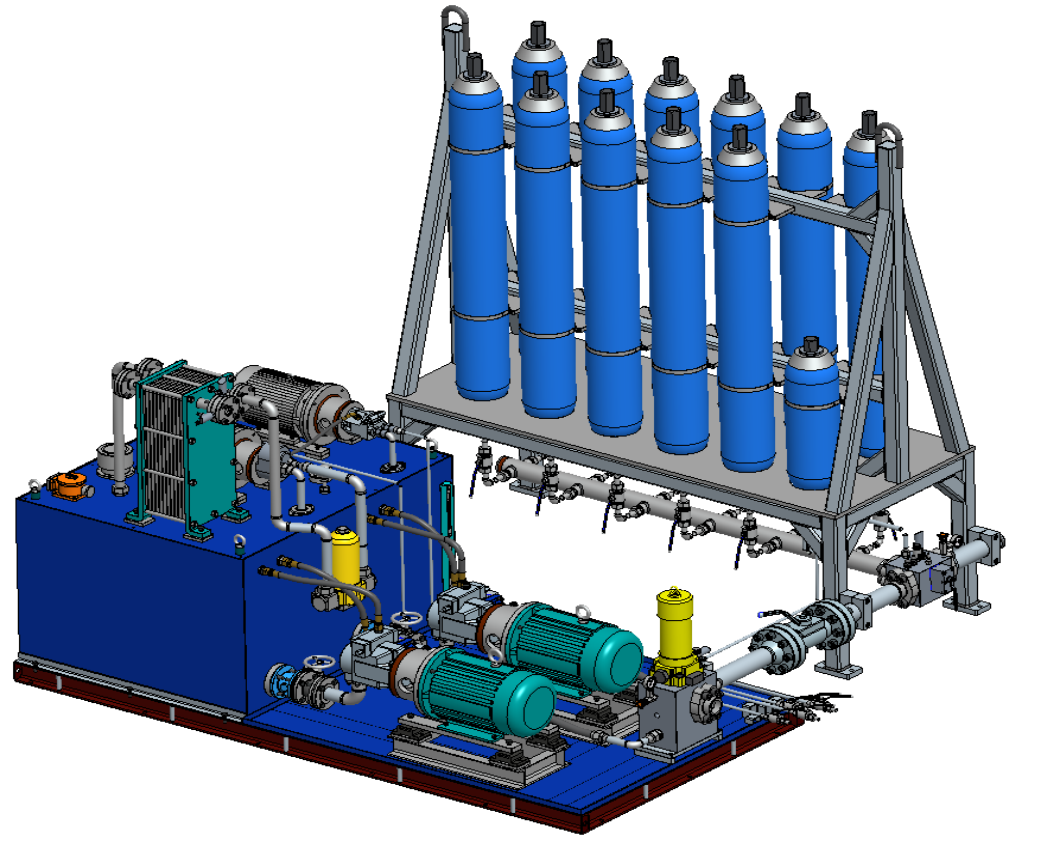

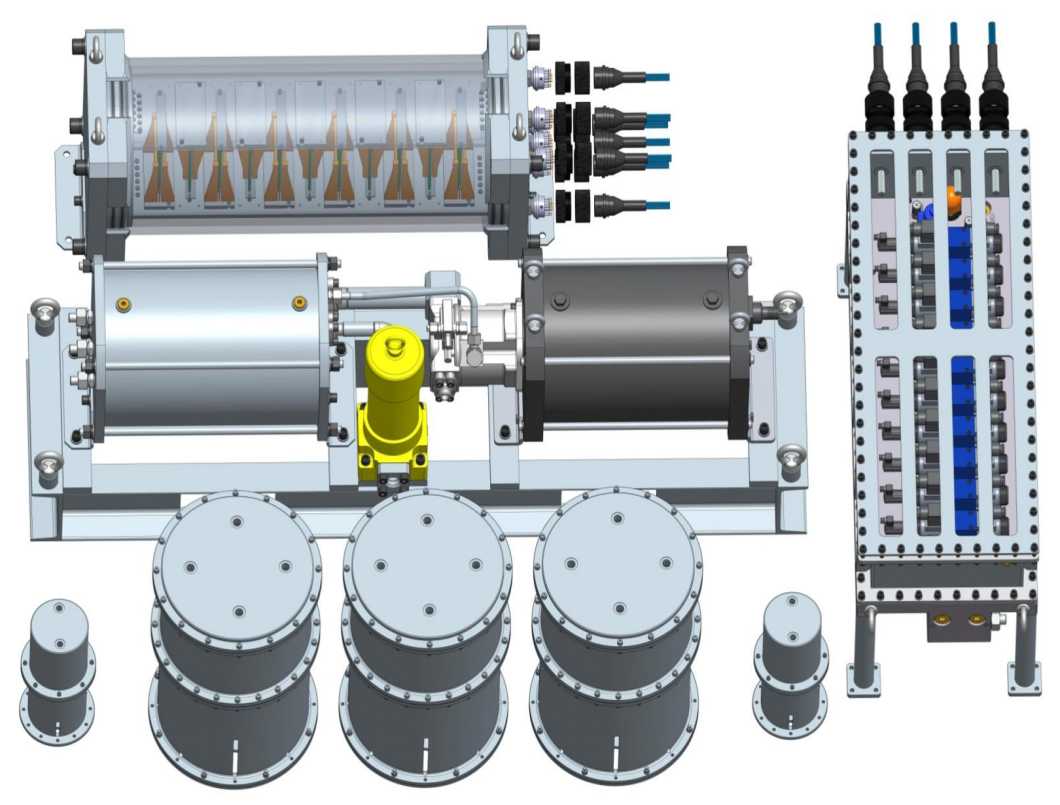

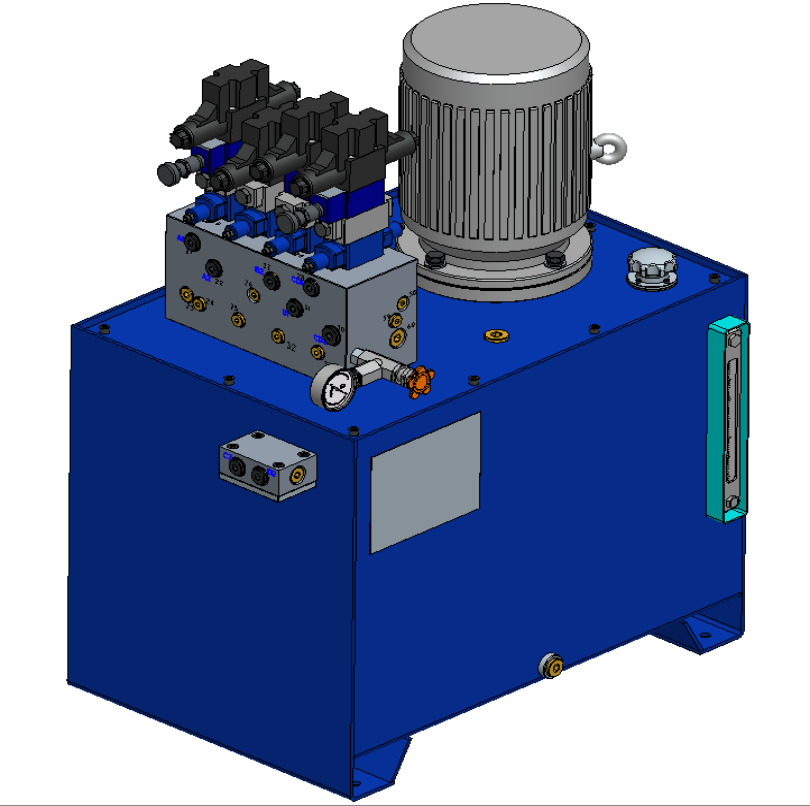

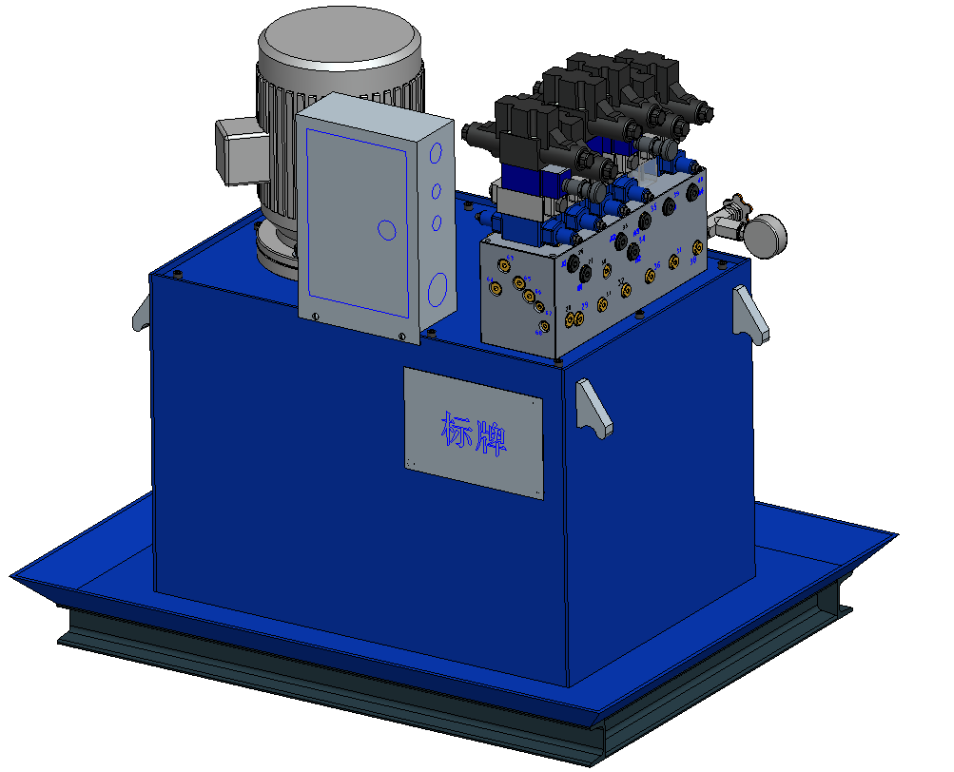

Three-dimensional diagram

10. Hydraulic station

Main system technical parameters

Rated system pressure: 16MPa, rated flow rate: 8.4L/min, motor power: 3KW, oil tank capacity: 130L

hydraulic schematic diagram

Three-dimensional diagram

11. Swing cylinder performance test hydraulic station

technical parameter

Rated system pressure: 21MPa, rated flow rate: 520L/min, motor power: 250KW, oil tank capacity: 4000L

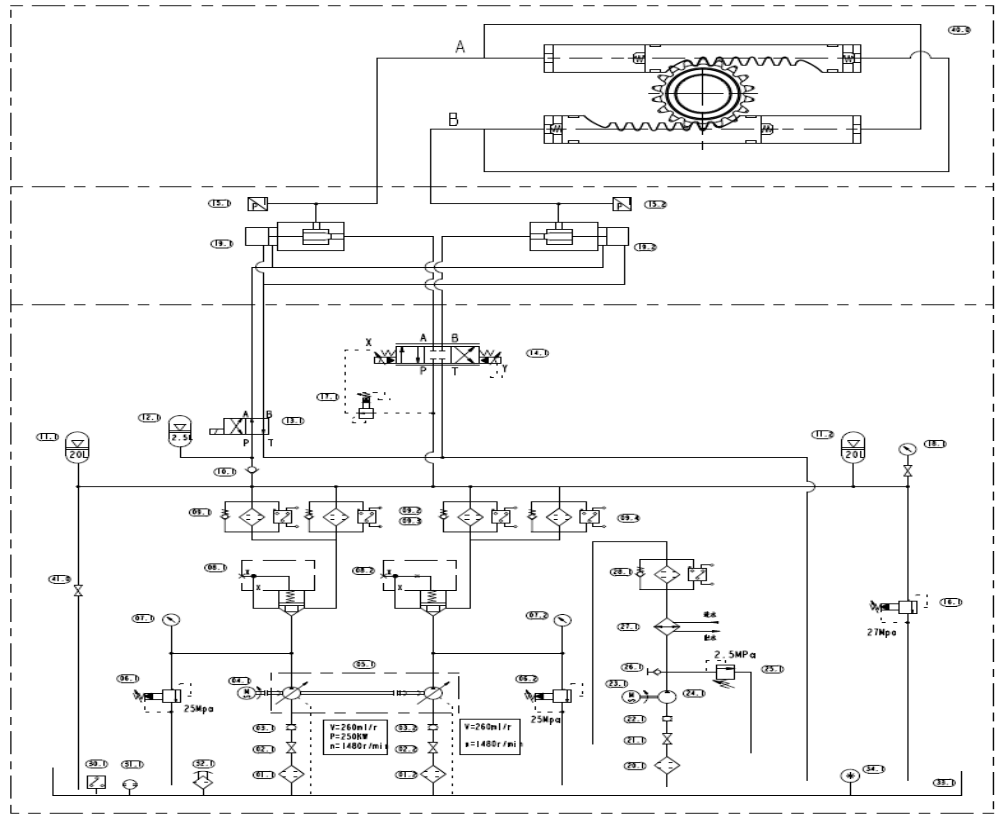

hydraulic schematic diagram

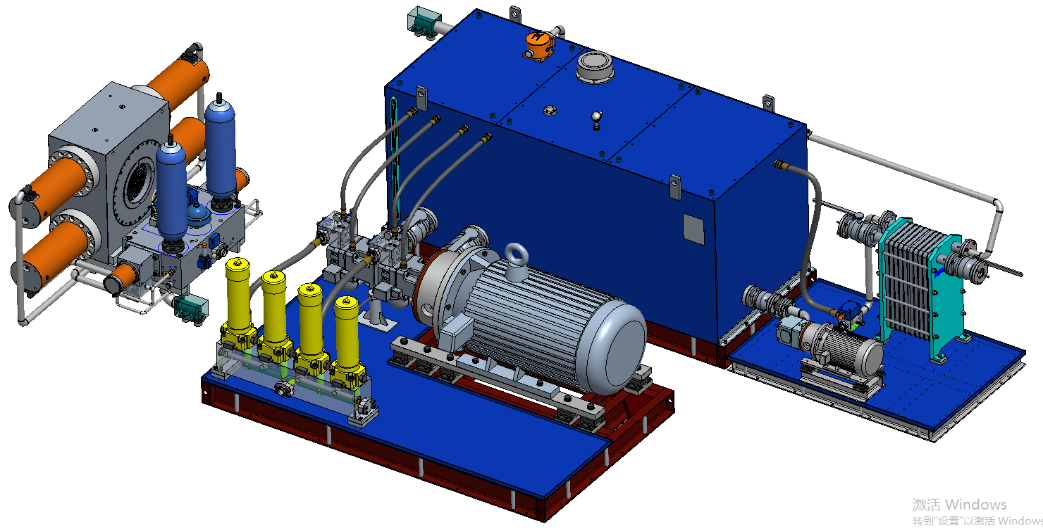

Three-dimensional diagram

12. Hydraulic drive device

technical parameter

Main rated system pressure: 21MPa, rated flow rate: 100L/min, motor power: 15KW, oil tank capacity: 1000L

hydraulic schematic diagram