Hydraulic Nut

A hydraulic nut is a high-precision and high-reliability bolt-tensioning device that applies axial tensile force to a bolt through hydraulic pressure to generate a stable and repeatable preload.

It is widely used in applications requiring exceptional fastening accuracy and safety, such as metallurgy, wind power, nuclear energy, heavy machinery, bearing assembly, and turbine equipment.

Compared with traditional torque-based tightening, the hydraulic nut eliminates preload errors caused by friction coefficient variations, significantly improving connection reliability and installation efficiency.

Working Principle

When pressurized oil is pumped into the pressure chamber of the hydraulic nut, the piston moves axially upward, applying tension directly to the bolt. Once the designed preload is reached, the locking ring is tightened to hold the stretched position, and the hydraulic pressure is then released.

This principle overcomes the uncertainties of torque-controlled tightening, as the load is applied directly to the bolt shank rather than transferred through friction. It is particularly suitable for heavy-duty, high-vibration, high-temperature, or precision assembly environments, as well as confined spaces.

Selection Guidelines

1. Bolt Specification: The internal thread must match the bolt thread (metric, trapezoidal, UNC, UNF).

2. Required Preload: Choose a model capable of providing the target axial force.

3. Environment: Specify high temperature, humidity, or corrosive conditions before ordering.

4. Space: Verify that the nut’s diameter and height meet installation constraints.

5. Pressure: Ensure the hydraulic pump pressure matches the nut’s rated pressure.

Tianjin Uranus Hydraulic Machinery Co., Ltd. designs and manufactures metric, imperial, and customized non-standard hydraulic nuts. Thousands of units are operating reliably worldwide.

Product Examples

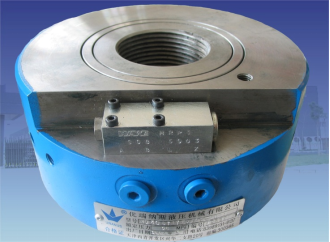

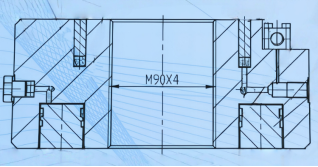

1. Hydraulic Nut M0308T205/130-10

Internal Thread: M90×4

Main Cylinder: OD205mm ID130mm Stroke10mm

Secondary Cylinder: OD150mm ID130mm Stroke15mm

Working Pressure: 25MPa Testing Pressure: 42MPa Medium: Hydraulic Oil

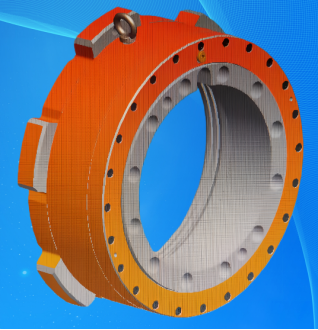

2. Hydraulic Nut UM1410φ340.2

Bore: Ø385 Rod: Ø355 Stroke: 12m

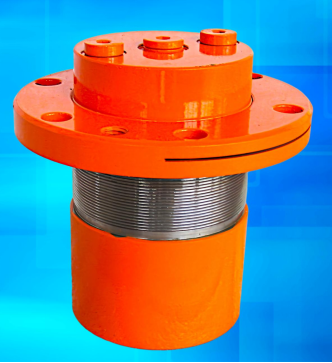

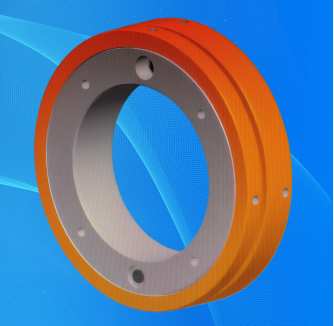

3、Hydraulic Nut UM1707 M160×6

Internal Thread: M160×6

Annular Cylinder: OD230mm ID185mm Stroke6mm

Working Pressure: 60MPa Testing Pressure: 70MPa Medium: Hydraulic Oil

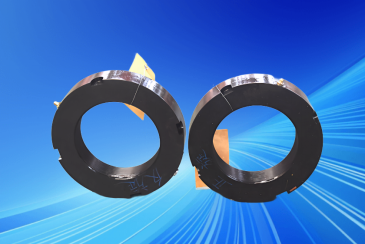

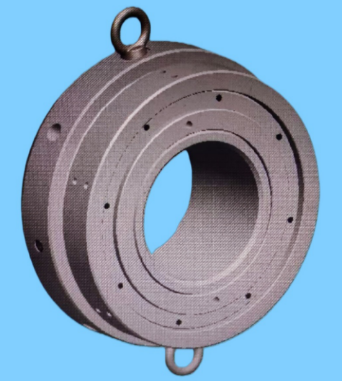

4 Hydraulic Nut Tr240×4

Internal Thread: Tr240×4 (Right-hand)

Annular Cylinder: OD330mm ID260mm Stroke10mm

Working Pressure: 50MPa Testing Pressure: 70MPa Medium: Hydraulic Oil

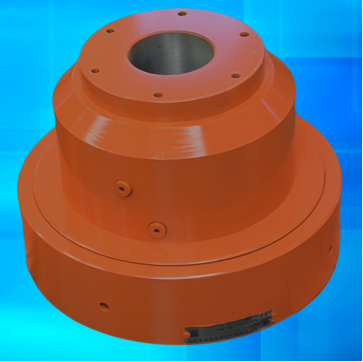

5 Hydraulic Nut YMQJ12 M200×3 LH

Internal Thread: M200×3 (Left-hand)

Annular Cylinder: OD270mm ID230mm Stroke8mm

Working Pressure: 35MPa Testing Pressure: 45MPa Medium: Hydraulic Oil