Clamping Hydraulic Cylinders for Continuous Casting and Rolling Lines

Clamping Hydraulic Cylinders for Continuous Casting and Rolling Lines

In the critical production processes of continuous casting and rolling—characterized by large-scale investment, high technical intensity, and uninterrupted operation—clamping hydraulic cylinders have far surpassed their traditional role as simple “clamping” components. As advanced products integrating precision mechanics, hydraulic transmission, and automatic control, they have become essential to ensuring production safety, improving product quality, enhancing operational efficiency, and extending equipment service life. The design sophistication, performance stability, and maintenance standards of these cylinders directly reflect the modernization level and overall competitiveness of the entire production line.

With over 30 years of accumulated expertise, Uranus has supplied thousands of clamping hydraulic cylinders to continuous casting and rolling lines worldwide. Renowned for stable operation, durability, and long service life, the products have maintained an outstanding record of zero quality incidents, earning widespread recognition and long-term trust from customers.

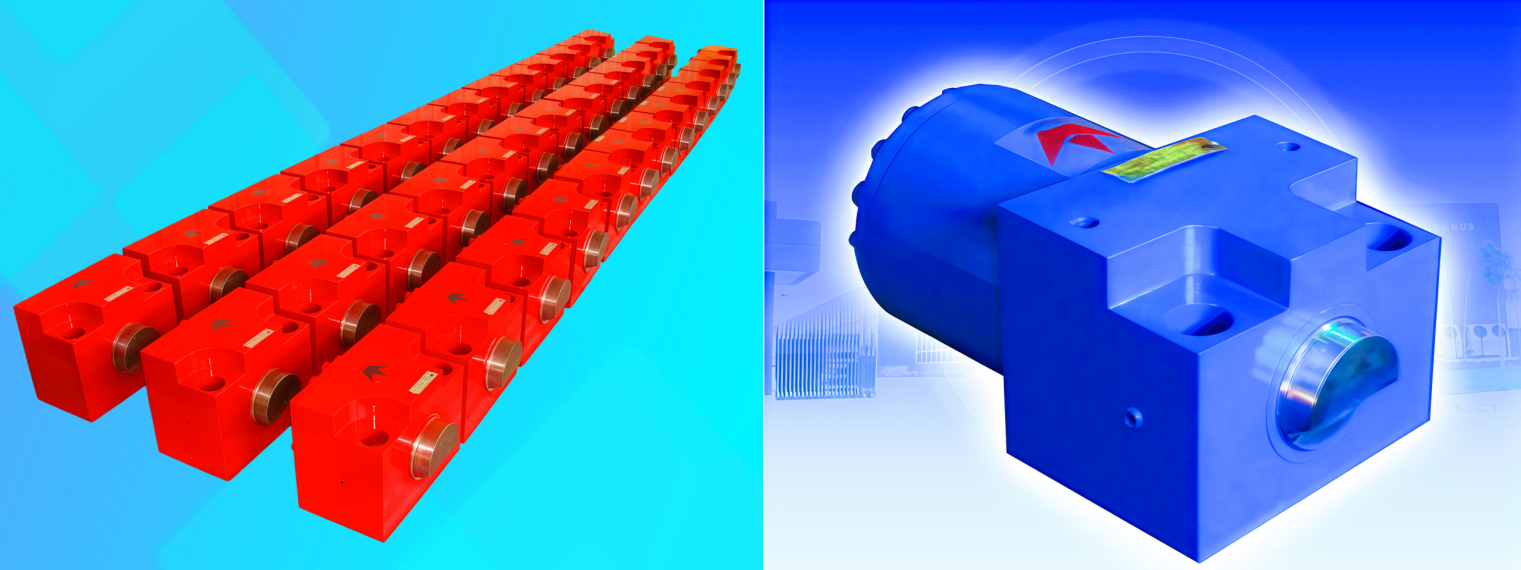

Product Examples

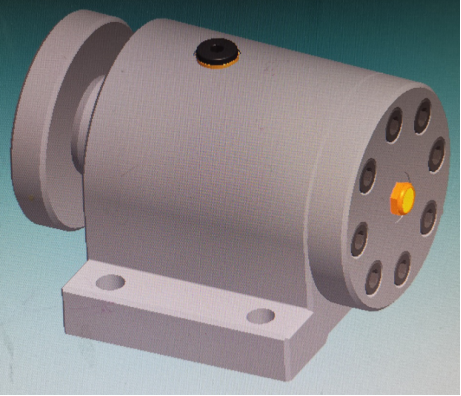

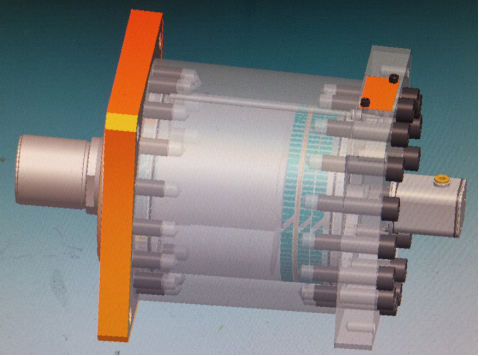

1.Clamping Cylinder

Cylinder Bore: 520 mm, Rod: 240/220 mm, Stroke: 245 mm

Working Pressure: 20 MPa, Test Pressure: 34.5 MPa

Medium: HFDU-VG46

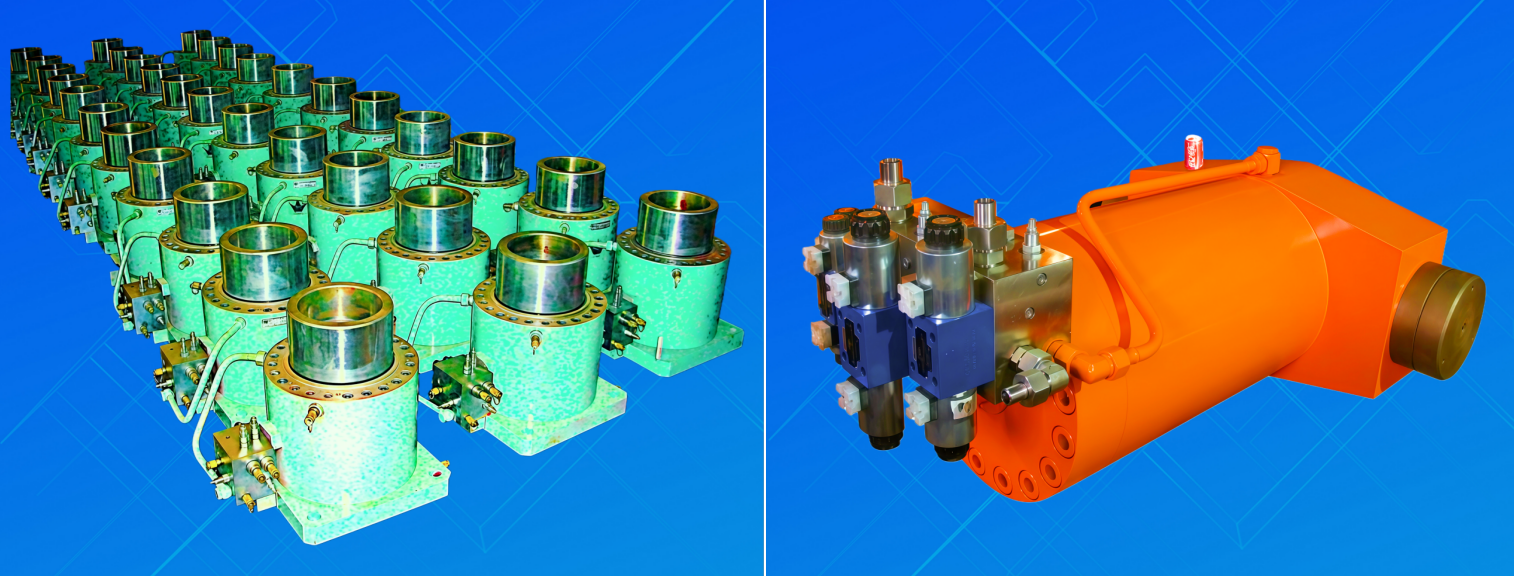

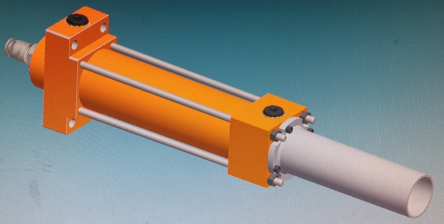

2.HAINZL Segment Clamping Cylinder

Cylinder Bore: 360 mm, Rod: 140 mm, Stroke: 200 mm

Working Pressure: 23 MPa, Test Pressure: 37.5 MPa

Medium: Water-Glycol

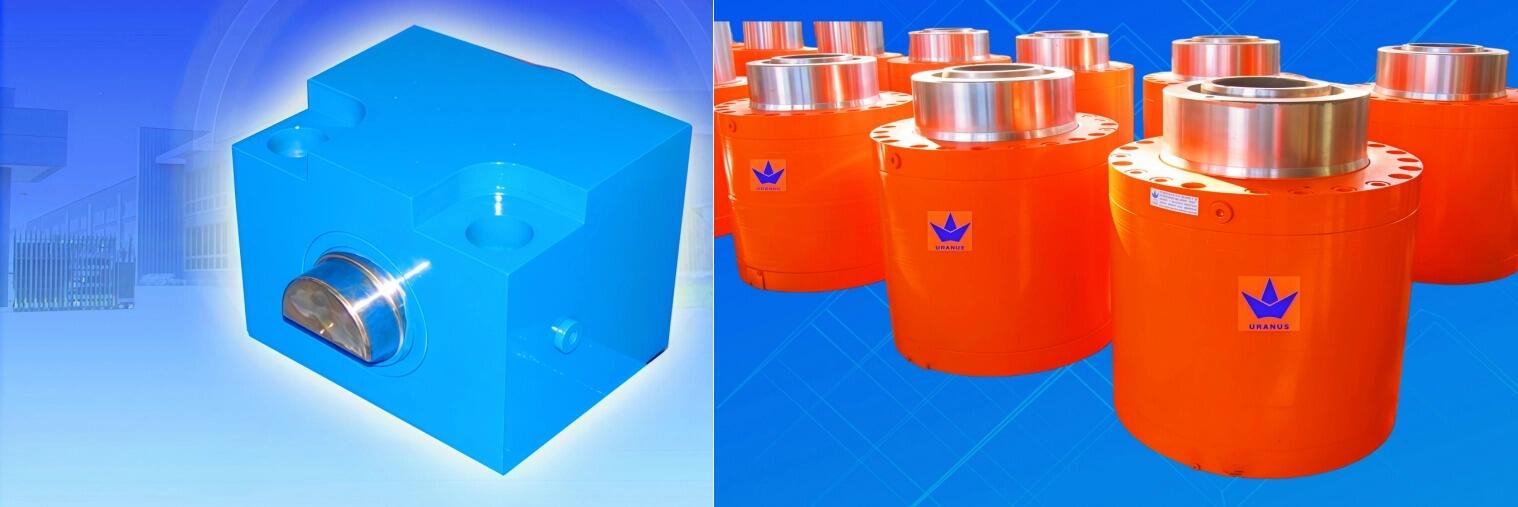

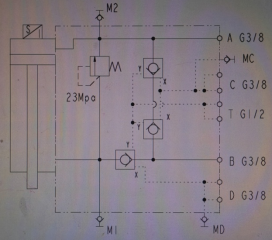

3.3.Clamping Cylinder

Cylinder Bore: 290 mm, Rod: 200/250 mm, Stroke: 140 mm

Working Pressure: 22 MPa, Test Pressure: 31.5 MPa

Medium: Water-Glycol

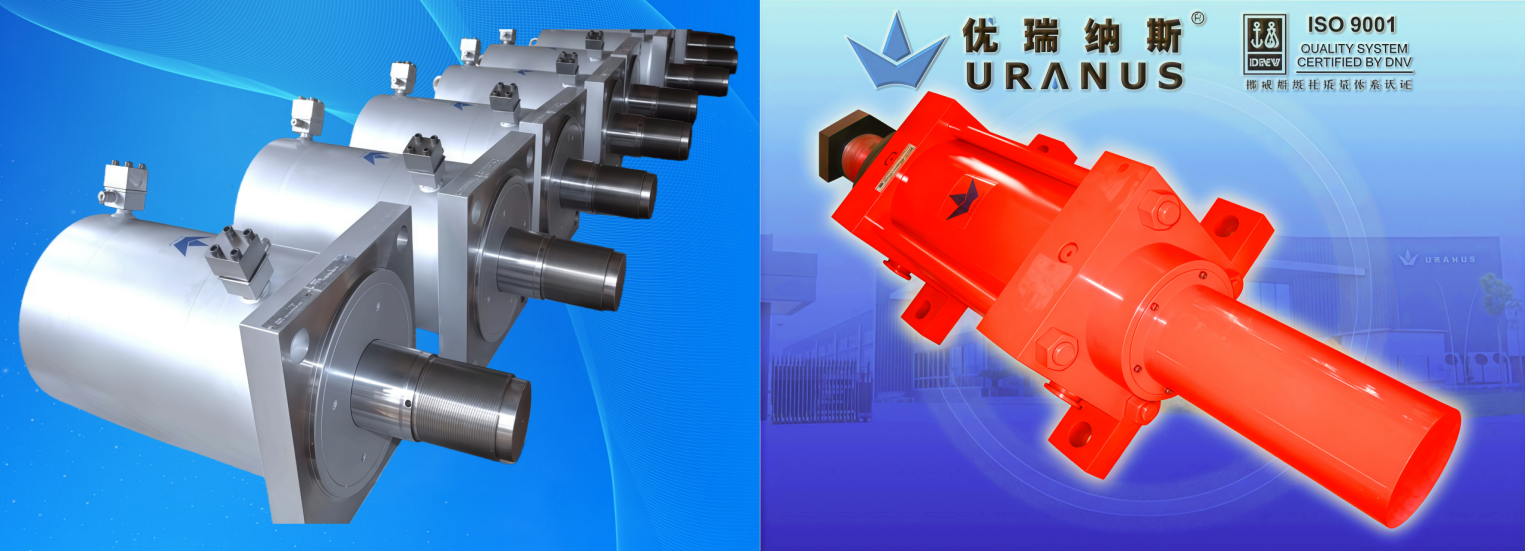

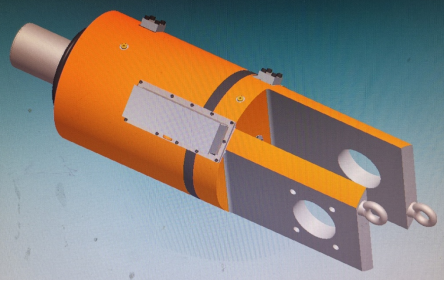

4.Arc Segment Clamping Cylinder

Cylinder Bore: 310 mm, Rod: 200/265 mm, Stroke: 230 mm

Working Pressure: 25 MPa, Test Pressure: 37.5 MPa

Medium: Hydraulic Oil

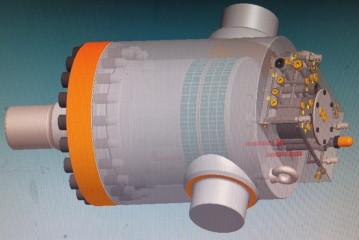

5.Servo Clamping Cylinder

Cylinder Bore: 450 mm, Rod: 200 mm, Stroke: 290 mm

Working Pressure: 25 MPa, Test Pressure: 31.5 MPa

Medium: Hydraulic Oil

Built-in displacement sensor

6. Vertical Clamping Cylinder

Cylinder Bore: 63 mm, Rod: 36 mm, Stroke: 240 mm

Working Pressure: 11.5 MPa, Test Pressure: 17.5 MPa

Medium: Hydraulic Oil

7.Clamping Cylinder

Cylinder Bore: 330 mm, Rod: 150 mm, Stroke: 195 mm

Working Pressure: 11.5 MPa, Test Pressure: 17.5 MPa

Medium: Hydraulic Oil

8. Clamping Cylinder 28042

Cylinder Bore: 80 mm, Rod: 70 mm, Stroke: 120 mm

Working Pressure: 29 MPa, Test Pressure: 36 MPa

Medium: Hydraulic Oil

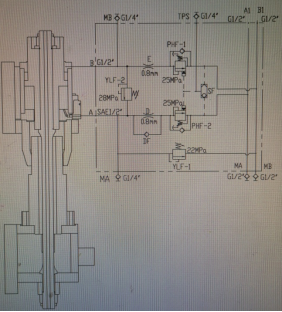

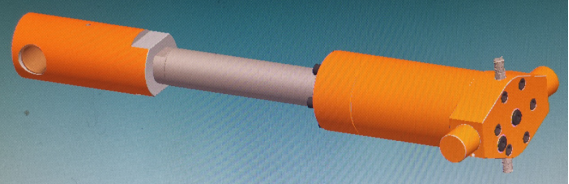

9.Horizontal Servo Clamping Cylinder

Cylinder Bore: 80 mm, Rod: 36 mm, Stroke: 285 mm

Working Pressure: 11.5 MPa, Test Pressure: 17 MPa

Medium: Hydraulic Oil

Built-in displacement sensor

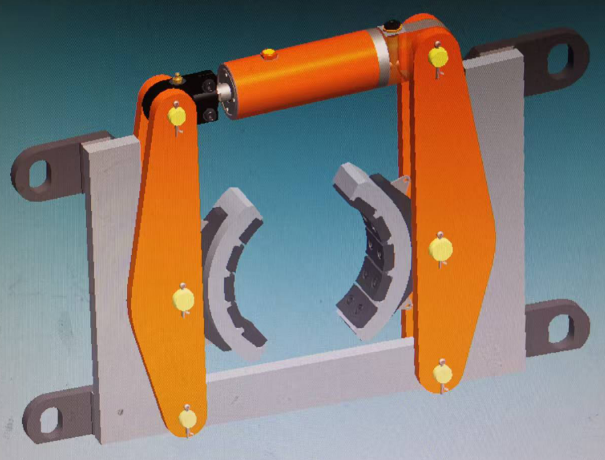

10.Spring Clamping Cylinder 28655 (Spring Applied, Hydraulic Released)

Cylinder Bore: 35 mm, Rod: 16 mm, Stroke: 10.4 mm

Brake Wheel Diameter: 140 mm, Clamping Torque: 550 Nm

Clamping Stroke: 5 mm, Spring Force: 6552 N

Release Pressure: 8.4 MPa, Release Stroke: 5.4 mm

Medium: Hydraulic Oil

11.Spring Clamping Cylinder 13749 (Spring Applied, Hydraulic Released)

Cylinder Bore: 125 mm, Rod: 100 mm, Stroke: 23 mm

Working Pressure: 17 MPa, Test Pressure: 25 MPa

Medium: Hydraulic Oil

Rated Clamping Force: 5699–11513 N

12.Spring Return Cylinder 28654 (Hydraulic Applied, Spring Released)

Cylinder Bore: 60 mm, Rod: 50 mm, Stroke: 12 mm

Working Pressure: 12 MPa, Test Pressure: 25 MPa

Medium: Hydraulic Oil