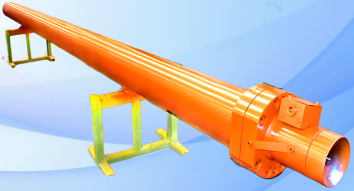

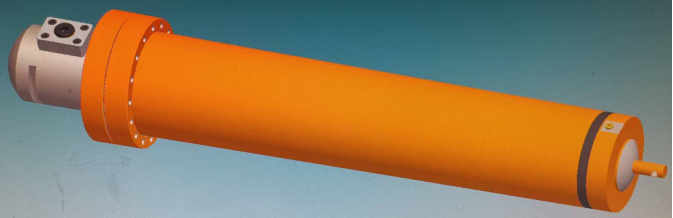

Photos of LF Ladle Refining Furnace Hydraulic Cylindersr

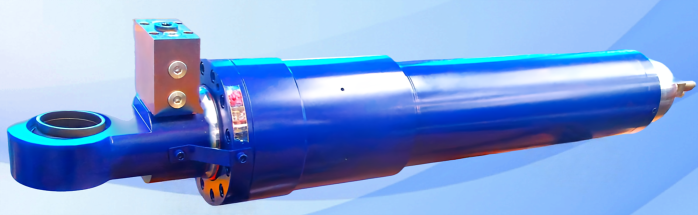

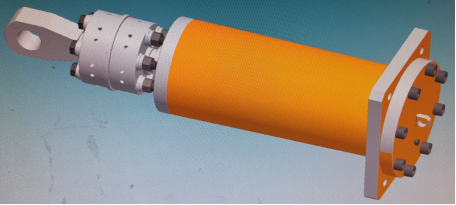

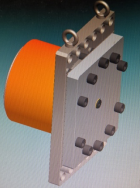

Furnace Cover Lifting Clinder

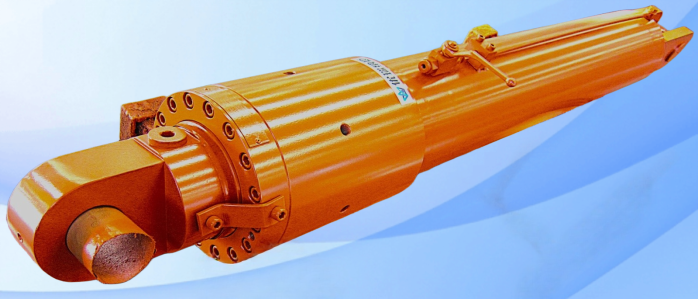

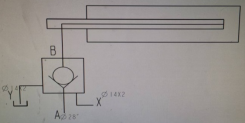

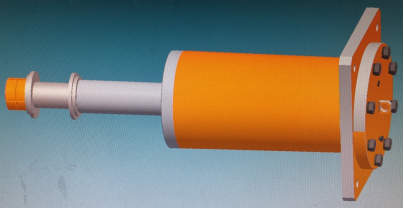

Electrode Clamping Clinder

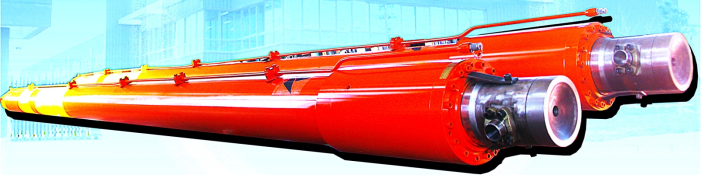

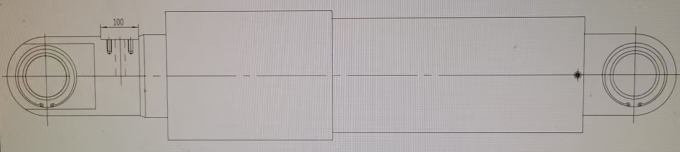

Electrod Lifting Cylinder

LF Ladle Refining Furnace Hydraulic Cylinders

The LF (Ladle Furnace) refining system plays a critical role in secondary metallurgy, ensuring precise temperature control, alloy adjustment, and high steel purity.

Uranus Hydraulic provides specialized LF furnace cylinders designed for high reliability, smooth performance, and long service life under extreme heat, dust, and heavy-duty operating conditions.

Main Hydraulic Cylinders

1) Furnace Cover Lifting Cylinder

Controls the lifting and opening of the LF furnace cover.

Performance Requirements:

● High Synchronization and Stability: Usually driven by 2 or 4 synchronized cylinders requiring uniform machining precision, sealing, and friction characteristics to ensure perfectly synchronized movement.

● Accurate Positioning and Locking: The hydraulic system must allow precise multi-position stops (working, maintenance, upper position) and secure holding without sagging.

● High Reliability and Long Life: The cylinder must sustain frequent operation with exceptional durability to minimize downtime.

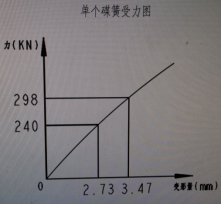

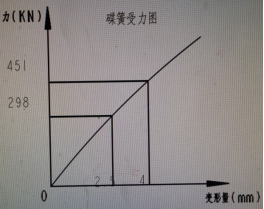

2) Electrode Clamping Cylinder

Responsible for clamping and releasing electrodes to ensure stable conduction and safety.

Performance Requirements:

● Provides continuous, stable clamping force to prevent electrode slipping.

● Designed with a “butterfly spring clamping, hydraulic release” mechanism for zero internal leakage.

● Maintains constant clamping force during long-term operation for safe and stable melting performance.

3) Electrode Lifting Cylinder

Precisely controls electrode movement based on arc feedback signals.

Performance Requirements:

● Adjusts electrode height according to arc current and voltage to maintain stable arc length and power input.

● Capable of rapid lifting under short-circuit or electrode-break conditions.

● Low static/dynamic friction and fast response ensure high-precision arc control.

Product Advantages

With over 30 years of experience, Uranus Hydraulic has supplied nearly a thousand LF furnace cylinders worldwide. These cylinders operate reliably for over a decade, serving major steel plants globally and maintaining long-term customer partnerships.

Application Examples

1. Furnace Cover Lifting Cylinder UZG1210R200-530

● Plunger Diameter: Ø200 mm Stroke: 530 mm

● Working Pressure: 12 MPa Test Pressure: 18 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Polyol

2. LF Furnace Cover Lifting Cylinder UZ1108R160-600

● Plunger Diameter: Ø160 mm Stroke: 600 mm

● Working Pressure: 14 MPa Test Pressure: 21 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Water-Glycol

3. LF Furnace Cover Plunger Cylinder UZGR0710R200-700

● Plunger Diameter: Ø220 mm Stroke: 700 mm

● Working Pressure: 15 MPa Test Pressure: 25 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Fatty Ester

4. Electrode Clamping Cylinder UG2412T220/90-98

● Bore: Ø220 mm Rod: Ø90 mm Stroke: 98 mm

● Working Pressure: 16 MPa Test Pressure: 24 MPa

● Working Medium: Hydraulic Oil

5. Electrode Clamping Cylinder UG2506T250/100-64

● Bore: Ø250 mm Rod: Ø100 mm Stroke: 64 mm

● Working Pressure: 16 MPa Test Pressure: 24 MPa

● Working Medium: Fatty Ester

6. Electrode Clamping Cylinder UY1408H250/90-60

● Bore: Ø250 mm Rod: Ø90 mm Stroke: 60 mm

● Working Pressure: 14 MPa Test Pressure: 21 MPa

● Working Medium: Water-Glycol

7. Electrode Lifting Cylinder UZGR2505T235-5200HS

● Plunger Diameter: Ø235 mm Stroke: 5200 mm

● Working Pressure: 15 MPa Test Pressure: 25 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: HFC46

● Feature: Built-in displacement sensor

8. Electrode Lifting Cylinder UZ1106R180-5300

● Plunger Diameter: Ø180 mm Stroke: 5300 mm

● Working Pressure: 16 MPa Test Pressure: 24 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Hydraulic Oil

9. Rotating + LF Furnace Electrode Lifting Cylinder UZG1108R140-4000

● Plunger Diameter: Ø140 mm Stroke: 4000 mm

● Working Pressure: 15 MPa Test Pressure: 21 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Water-Glycol

10. Electrode Lifting Cylinder UZ2204T100-2200

● Plunger Diameter: Ø100 mm Stroke: 2200 mm

● Working Pressure: 12 MPa Test Pressure: 18 MPa Starting Pressure: ≤0.3 MPa

● Working Medium: Fatty Ester