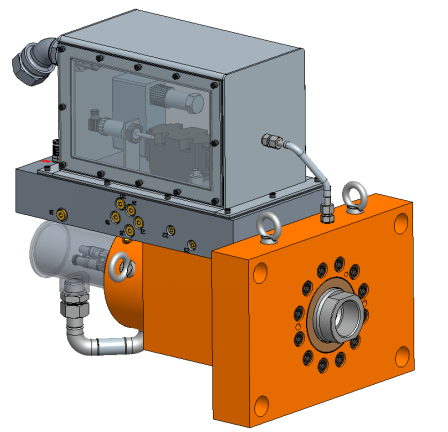

Precision Drive – Core Solution for Superior Casting Performance

Key Technical Advantages

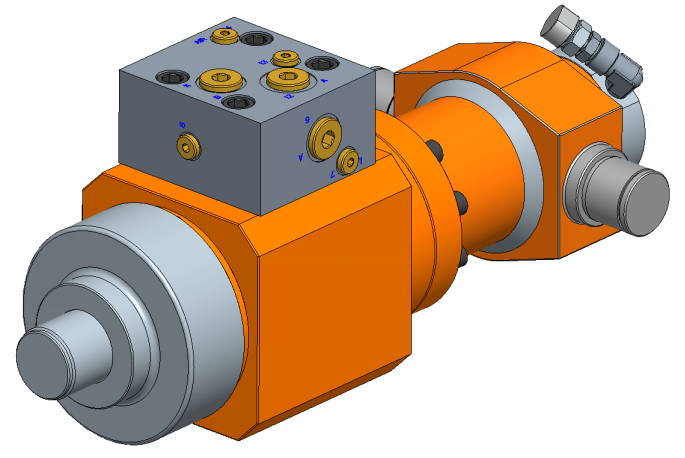

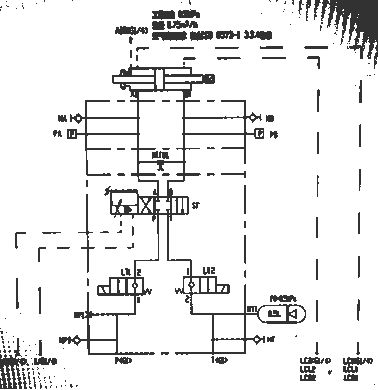

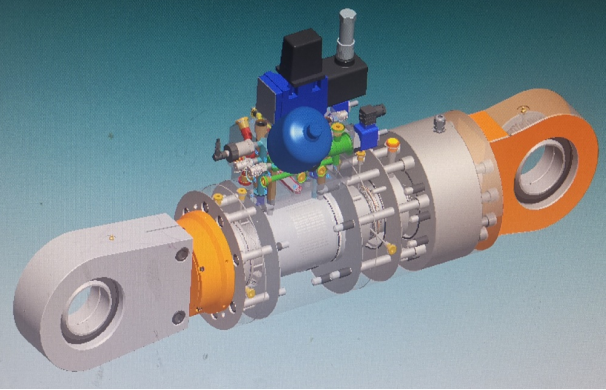

Uranus mold oscillation servo cylinders provide ultra-high precision and fast dynamic response for modern continuous casting. With electro-hydraulic direct drive and fully integrated digital control, amplitude, frequency, and waveform skew can be tuned online without shutdown. The cylinder ensures precise negative slip arc oscillation, improving lubrication and preventing sticking.

Product Features

● High precision control: Micron-level amplitude; millisecond frequency response

● Dual oscillation modes: Supports sinusoidal and non-sinusoidal waveforms

● Independent strand control: Multi-strand CCMs with per-strand parameter tuning

● Smart connectivity: MES/expert system integration for remote monitoring, diagnostics, predictive maintenance

● Rugged & reliable: Long service life, low maintenance, stable under harsh conditions

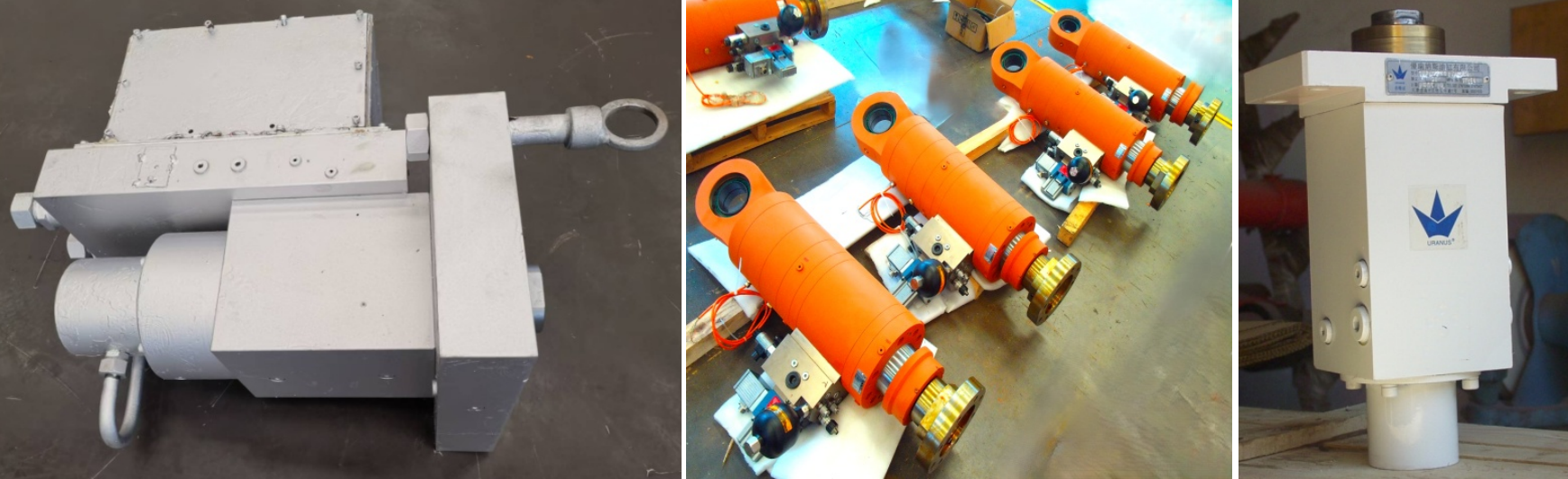

expansion and contraction cylinder for coiler

Benefits

Improved surface quality, reduced oscillation marks

Higher yield and operational efficiency

Supports high casting speed, increased productivity

Energy savings and lower operating costs

Easy installation, operation, and maintenance

Applications

Extensively used in high-efficiency billet, bloom, and slab continuous casting machines for both steel and non-ferrous metals.

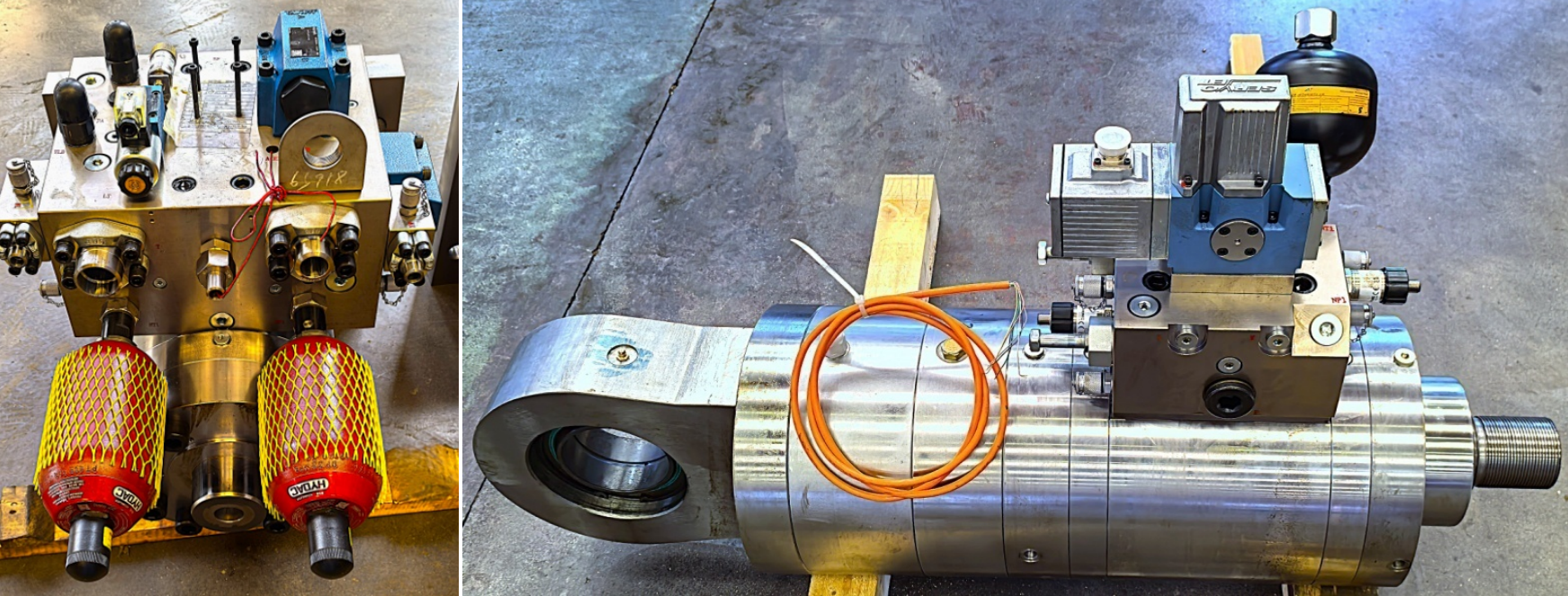

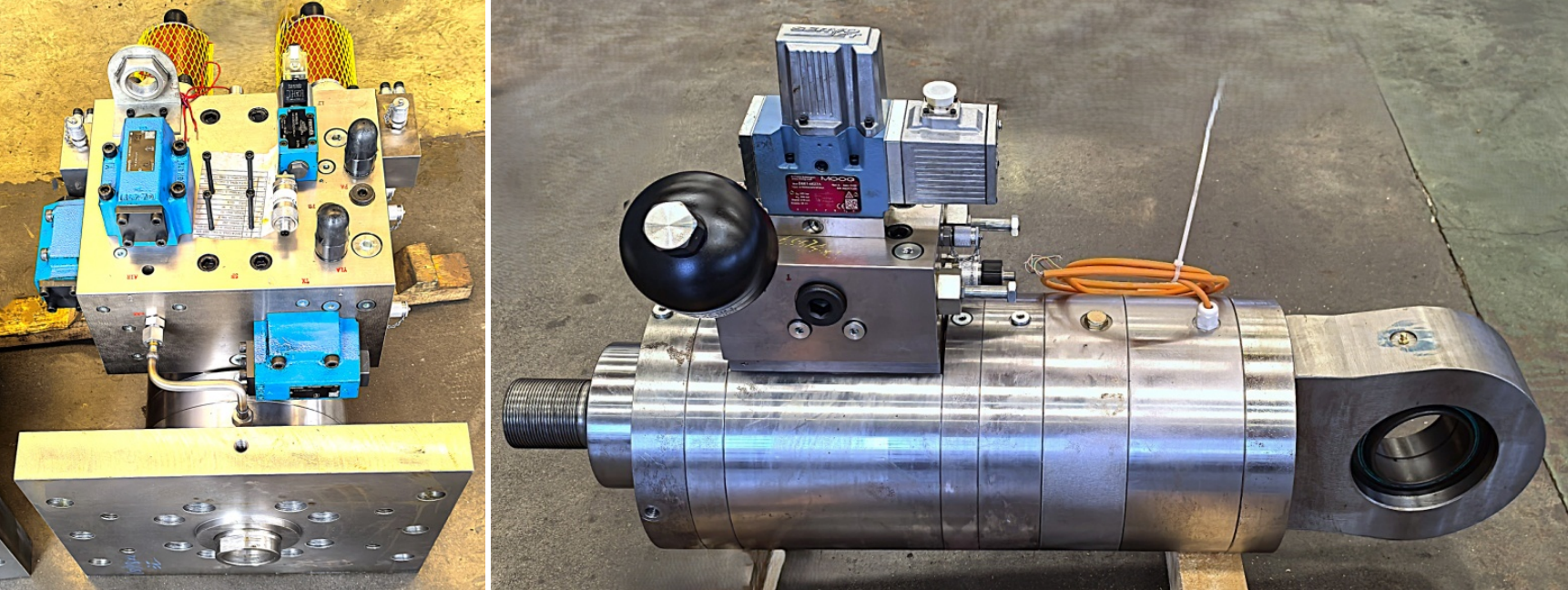

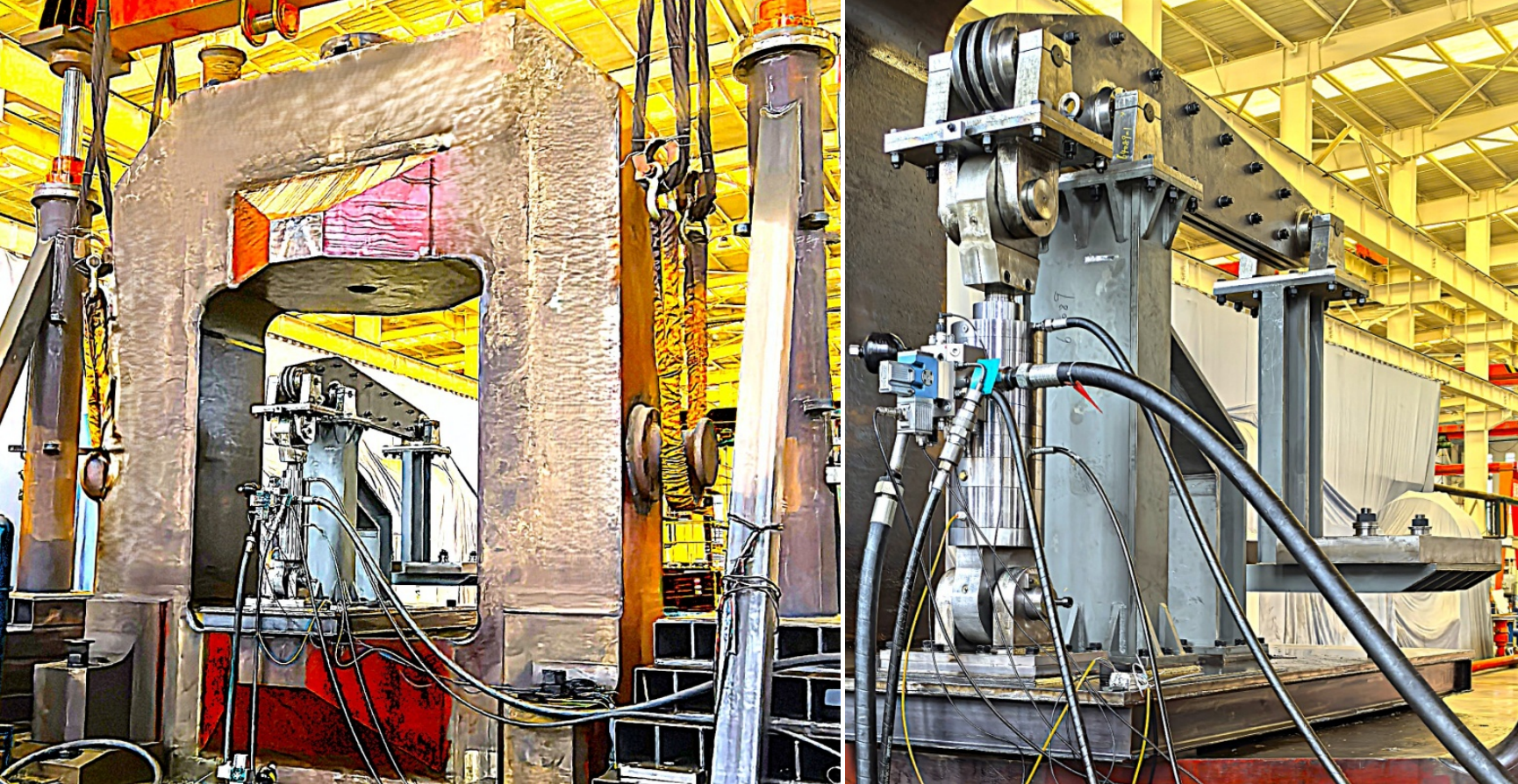

Testing & Verification

Our in-house test benches simulate full-load conditions and provide custom vibration trials with complete reports including data logging and waveform analysis.

Why Choose Us

With 20+ years of expertise, Uranus has developed over 20 models and delivered hundreds of servo oscillation systems worldwide—trusted for innovation, reliability, and performance.

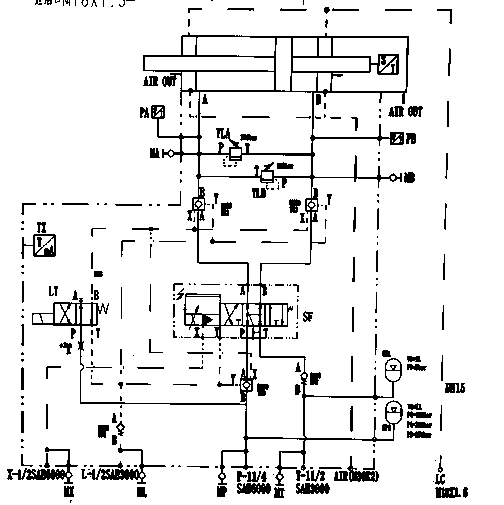

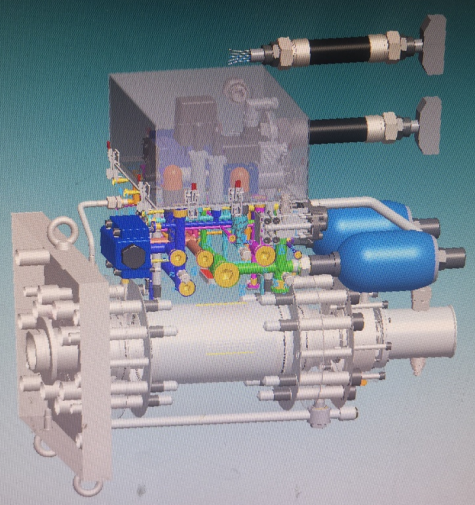

Photos of Crystallizer Vibration Servo Hydraulic Cylinder Performance Test Bench

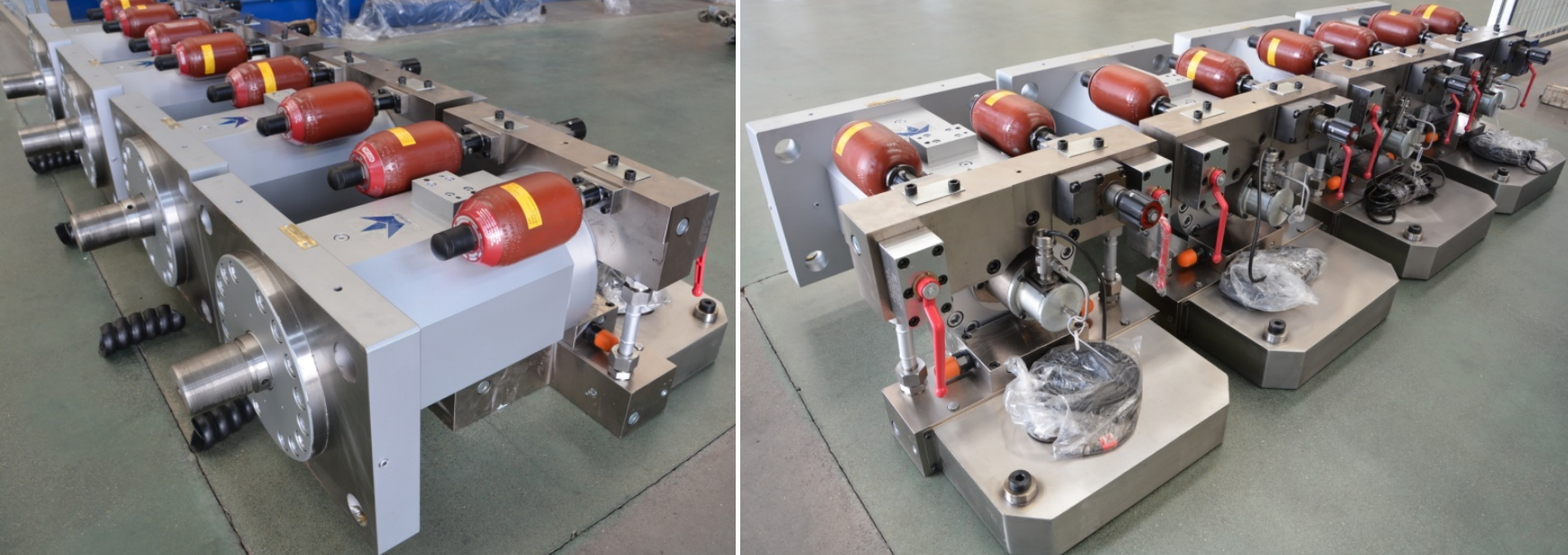

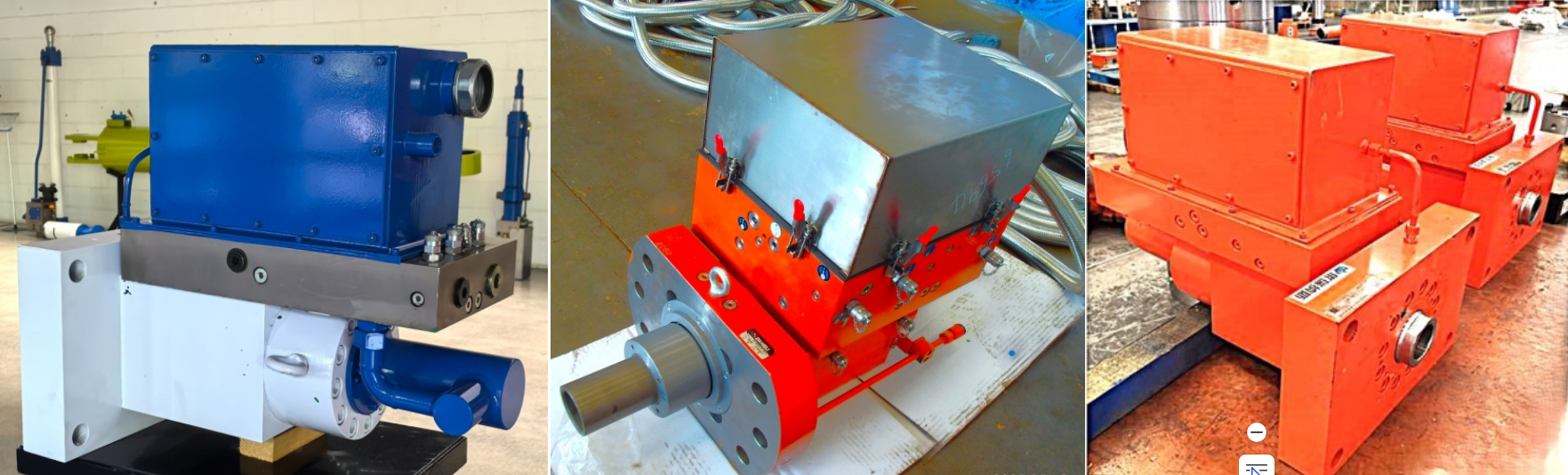

Typical Models & Specifications

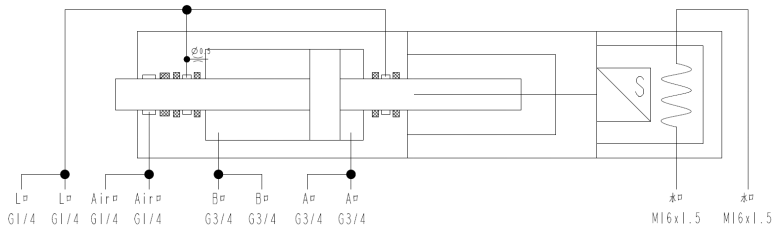

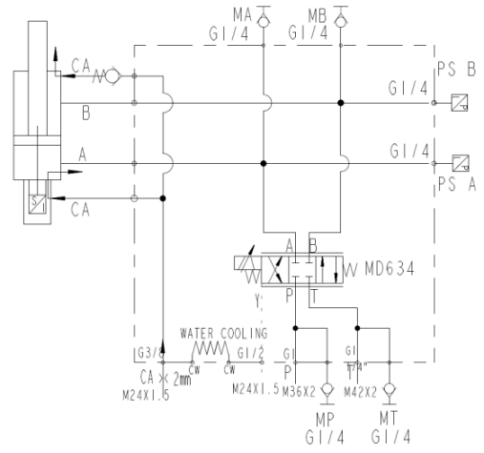

1、Model: USYR2501R140/90-50LJHS+FK

Bore 140 mm; Rod 90 mm; Stroke 50 mm

Pressure: Working 25 MPa; Test 31.5 MPa

Medium: Water-glycol; Seal: FKM

Built-in displacement sensor; servo valve block

Servo valve: 75 L/min, max 350 bar; 24V, ±10 mA, feedback 4–20 mA

Validation: Load 4500 Kg, vibration 193–325 OPM, accuracy within ±0.02 mm

Dynamic Characteristics: 25% of maximum signal value 60 Hz (9 slope line)

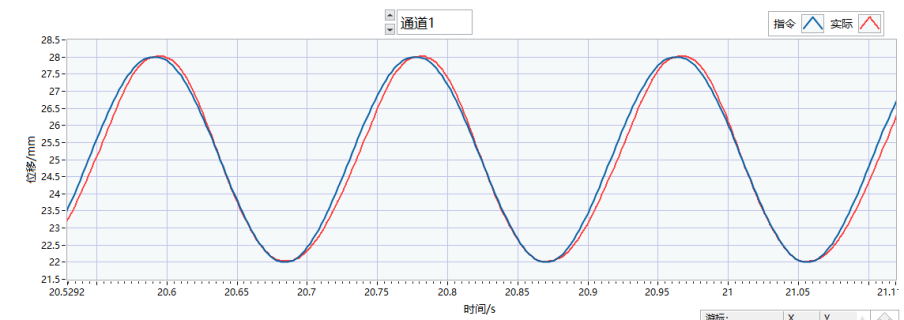

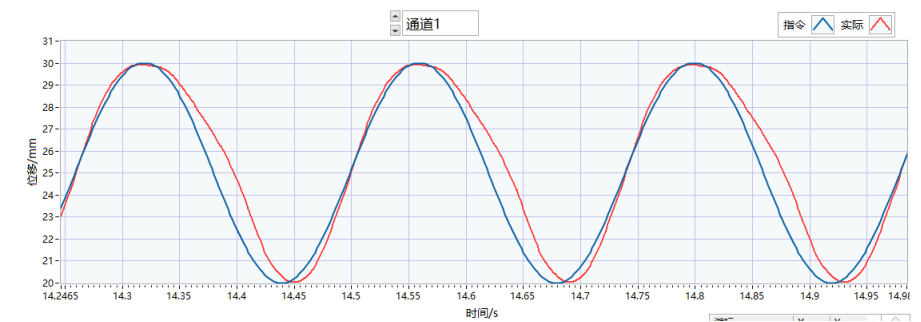

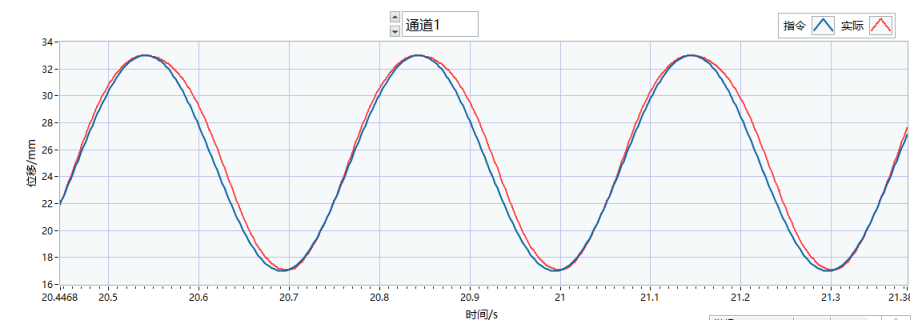

Load Test Curves of Crystallizer Servo Vibration Hydraulic Cylinder (Load: 4500Kg)

1)Total Stroke: 6mm (±3mm); Oscillation Frequency: 325 OPM;

Accuracy: ±0.025 ~ -0.02mm. Refer to the figure below.

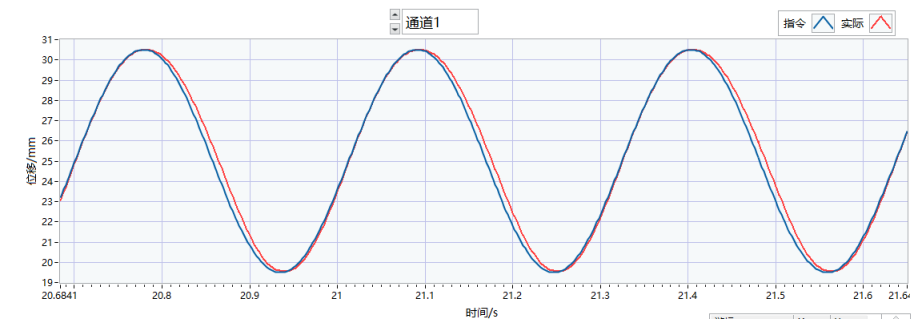

2) Total Stroke: 10mm (±5mm); Oscillation Frequency: 250 OPM;

Accuracy: ±0.07 ~ -0.02mm. Refer to the figure below

3) Total Stroke: 16mm (±8mm); Oscillation Frequency: 200 OPM;

Accuracy: ±0.015 ~ -0.05mm. Refer to the figure below.

4) Total Stroke: 11mm (±5.5mm); Oscillation Frequency: 193 OPM;

Accuracy: ±0.015 ~ -0.05mm. Refer to the figure below.

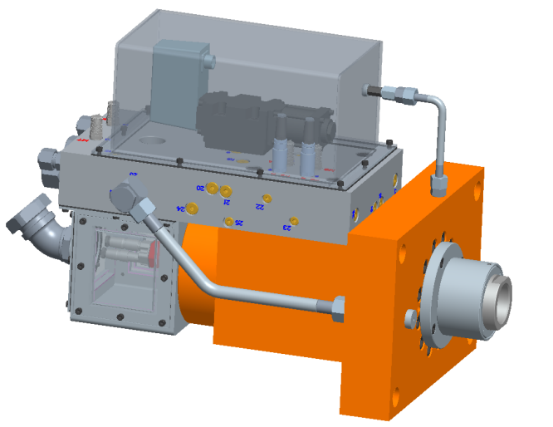

2、Model: USYR2501R160/90-50LJHS+FK

Bore 160 mm; Rod 90 mm; Stroke 50 mm

Pressure: Working 25 MPa; Test 31.5 MPa

Medium: Fatty ester; Temp −10℃~+80℃

Built-in displacement sensor;

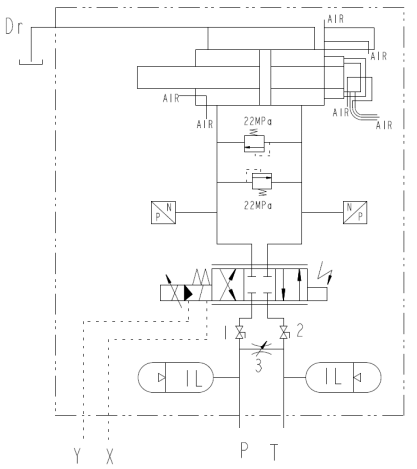

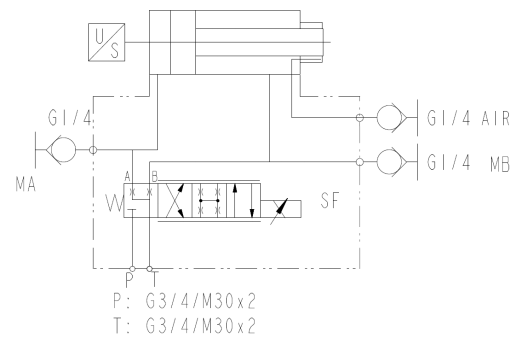

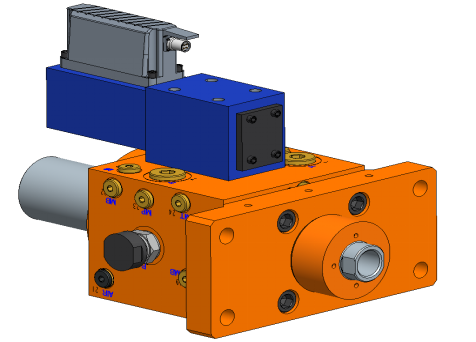

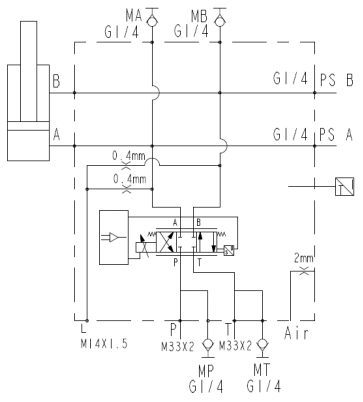

3、Model: 125/90-25

Bore 125 mm; Rod 90 mm; Stroke 25 mm

Pressure: Rated 21 MPa; Test 31.5 MPa

Built-in LVDT; closed-loop servo

Valve box & rod boot pressurized with air for cooling/dust.

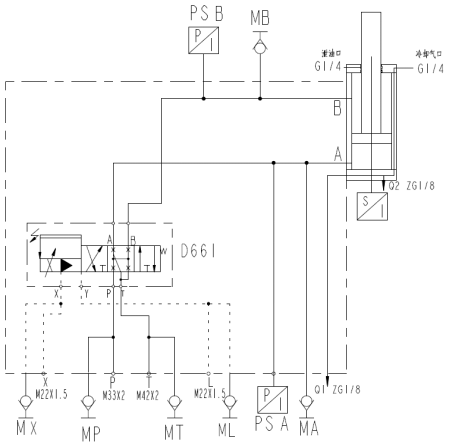

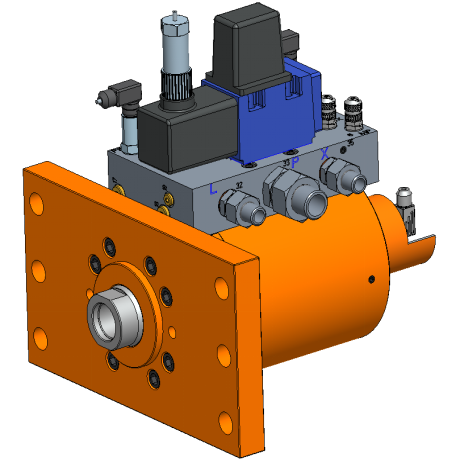

4、Model: 200/90-25

Bore 200 mm; Rod 90 mm; Stroke 25 mm

Pressure: Rated 21 MPa; Test 31.5 MPa

Built-in displacement sensor; servo block with accumulator & valves

5、Model: 80/45-25

Bore 80 mm; Rod 45 mm; Stroke 25 mm

Pressure: Rated 25 MPa; Test 32 MPa

Built-in displacement sensor; closed-loop

6、Model: 100/70-30

Bore 100 mm; Rod 70 mm; Stroke 30 mm

Pressure: Rated 21 MPa; Test 25 MPa

Built-in displacement sensor; closed-loop

7、Model: 125/90-25 (dust/cooling type)

Bore 125 mm; Rod 90 mm; Stroke 25 mm

Pressure: Rated 16 MPa; Test 30 MPa

Built-in displacement sensor; closed-loop; dust cover with air cooling

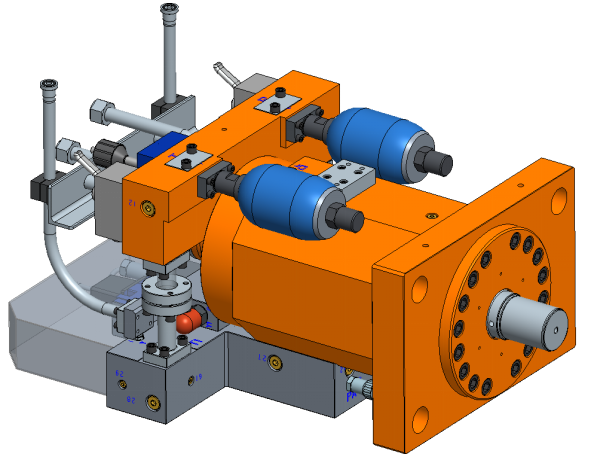

8、Model: 100/70/70-33 (double-rod equal-speed)

Bore 100 mm; Rod 70/70 mm; Stroke 33 mm

Pressure: Rated 10 MPa; Test 15 MPa

Double-rod equal-speed design; built-in displacement sensor

Cooling water jacket protects sensor chamber under high temp