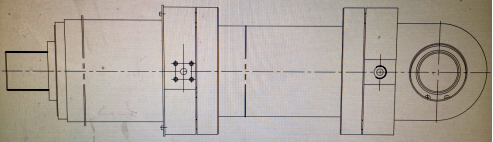

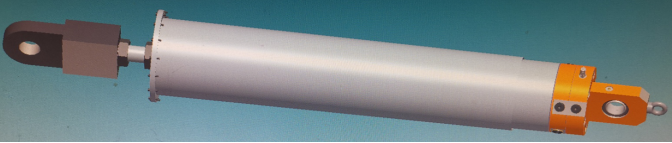

LD Converter Hydraulic Cylinder Photo

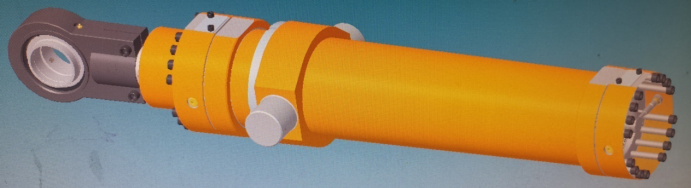

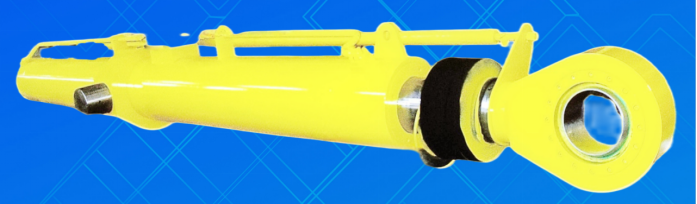

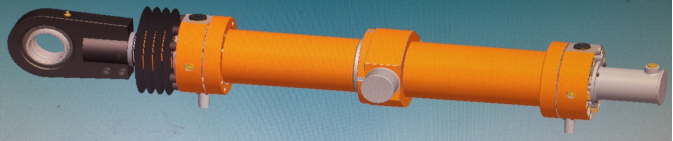

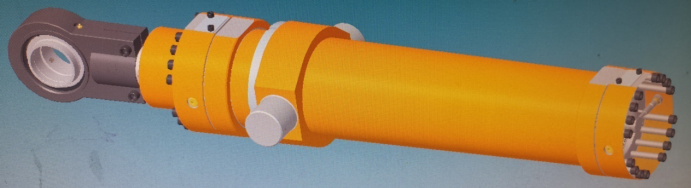

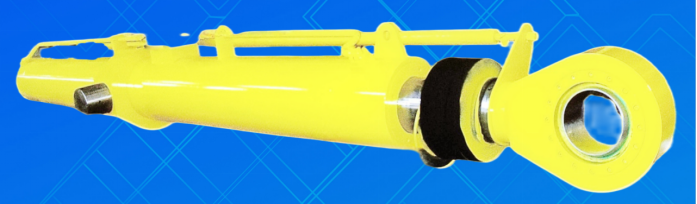

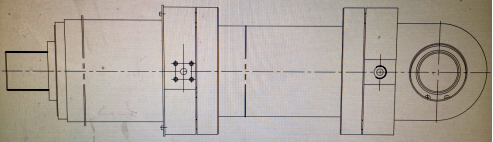

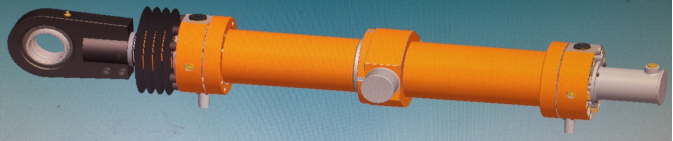

Tilting Cylinder of LD Converter

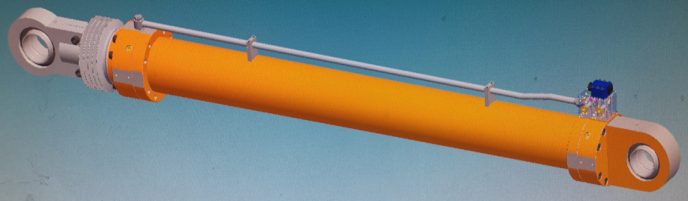

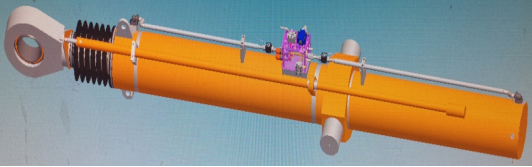

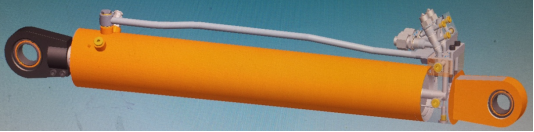

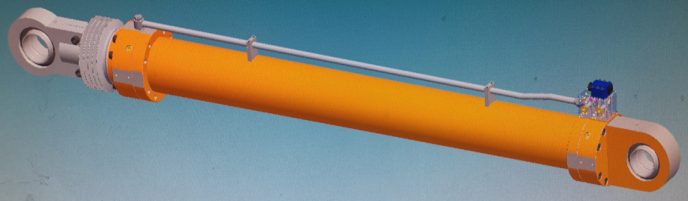

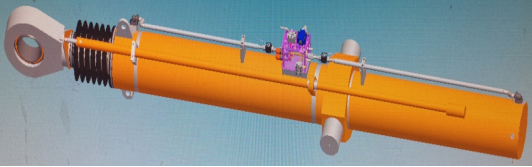

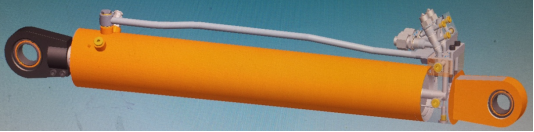

LD Converter Fume Hood Lifting High-Temperature Hydraulic Cylinder

LD Converter Fume Hood Lifting High-Temperature Hydraulic Cylinder

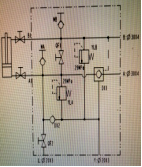

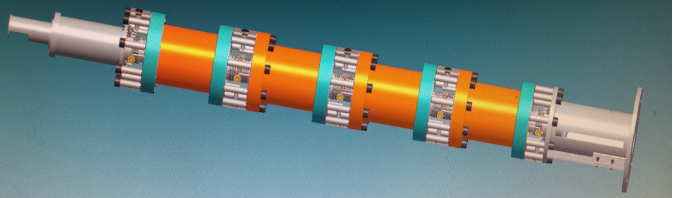

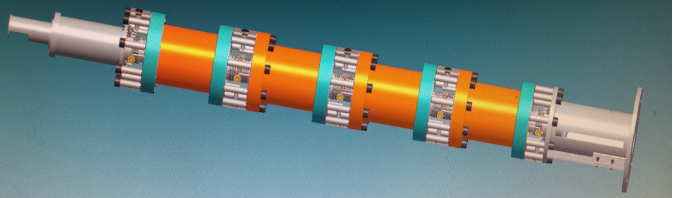

4-Cylinder Synchronous Lifting Hydraulic Cylinders for LD Converter Skirt Hood

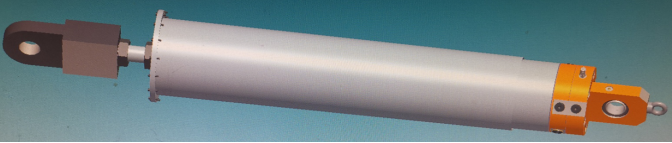

LD Converter Hydraulic Cylinders

The LD (Linz-Donawitz) converter is a key steelmaking facility used to refine molten iron from the blast furnace into high-quality steel through decarburization, dephosphorization, and desulfurization.

Uranus Hydraulic provides two main types of hydraulic cylinders for LD converters, ensuring stable performance under extreme temperature, dust, and heavy-load conditions.

1) LD Converter Tilting High-Temperature Hydraulic Cylinder

This cylinder drives the entire converter body to rotate 360° around its trunnion, enabling:

● Tilting the mouth for charging scrap and hot metal

● Vertical positioning for oxygen blowing

● Controlled tilting for tapping molten steel

● Inverted tilting for slag discharge

Performance Requirements:

● Massive Thrust:

The total weight of the converter with molten steel and slag exceeds 1,000 tons, requiring enormous torque output.

● Smooth and Precise Control:

The tilting speed must be extremely slow and uniform during tapping, demanding high-precision hydraulic control.

● High Reliability:

The system must operate reliably under high temperature, heavy load, dust, and severe contamination.

Over the past 30 years, Uranus Hydraulic has supplied hundreds of converter tilting cylinders worldwide, maintaining zero quality incidents with long-term stable performance and outstanding customer satisfaction.

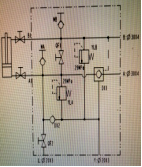

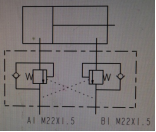

2) LD Converter Fume Hood Lifting High-Temperature Hydraulic Cylinder

The fume hood is essential for capturing fumes and dust during steelmaking, and its lifting system demands exceptional precision and reliability.

Performance Requirements:

● High Reliability:

Failure can halt the entire converter operation; cylinders must function stably in extreme environments.

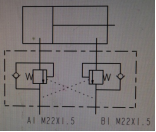

●Excellent Synchronization:

Large hoods are driven by 2–4 cylinders, which must maintain precise synchronization to prevent jamming or misalignment.

●Accurate Positioning:

Multiple preset positions (“working”, “standby”, “maintenance”) require precise stop control for effective dust removal.

●Strong Thrust and Stability:

The hood’s large mass and deformation risk demand sufficient push-pull force and stable operation.

Uranus cylinders feature a self-developed synchronized flow divider system for perfect multi-cylinder coordination. Each cylinder is equipped with a cooling water jacket and stainless-steel telescopic protective cover, ensuring reliable long-term operation in high-temperature, dusty environments.

Their performance and service life significantly surpass similar products, making them the preferred choice of leading steel enterprises.

Application Examples

1. Tilting High-Temperature Hydraulic Cylinder UYR2305R320/220-3630

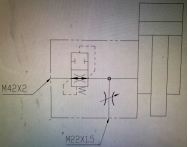

Bore: Ø320 mm Rod: Ø220 mm Stroke: 3630 mm Adjustable Cushion in Rodless Chamber (Stroke: 80 mm)

Working Pressure: 14 MPa Test Pressure: 21 MPa

Working Medium: Water-Glycol Feature: Bellows-type flame-retardant dust cover

2. Hot Metal Ladle Tilting Servo Hydraulic Cylinder TURZT13Z300/280-3875W

Bore: Ø300 mm Rod: Ø280 mm Stroke: 3875 mm

Working Pressure: 13 MPa Test Pressure: 25 MPa

Working Medium: Water-Glycol Feature: Built-in displacement sensor for high-precision servo control

3. Hot Metal Ladle Tilting High-Temperature Hydraulic Cylinder UYR0712R320/220-2500LT+FC+FZ

Bore: Ø320 mm Rod: Ø220 mm Stroke: 2500 mm Cushion: Dual-chamber cushion, 80 mm each side

Working Pressure: 25 MPa Test Pressure: 37.5 MPa

Working Medium: Water-Glycol Feature: Piston rod equipped with stainless-steel telescopic dust cover

4. Tilting High-Temperature Hydraulic Cylinder UGR2310Z320/220-3300THA+FK(1)

Bore: Ø320 mm Rod: Ø220 mm Stroke: 3630 mm Cushion: Adjustable cushion in rodless chamber (80 mm)

Working Pressure: 25 MPa Test Pressure: 31.5 MPa

Working Medium: Hydraulic Oil Feature: Piston rod equipped with bellows-type flame-retardant dust cover

5. Skirt Hood Synchronous Lifting High-Temperature Hydraulic Cylinder UYR1308R125/70-640

Bore: Ø125 mm Rod: Ø70 mm Stroke: 640 mm

Working Pressure: 14 MPa Test Pressure: 21 MPa

Working Medium: Water-Glycol Feature: Cylinder body with water-cooling jacket; piston rod with heat- and dust-proof protective cover

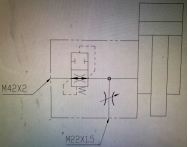

Synchronized Flow Divider Cylinder UF21L200/80-214X4

Bore: Ø400 mm Rod: Ø80 (90) mm Stroke: 214 mm

Working Pressure: 14 MPa Test Pressure: 21 MPa

Working Medium: Water-Glycol Feature: Supplies equal-volume hydraulic medium to four skirt hood lifting cylinders, ensuring precise synchronous lifting

6. Fume Hood Lifting Hydraulic Cylinder UY2508Z125/90-700HA+JJKG

Bore: Ø125 mm Rod: Ø90 mm Stroke: 700 mm Cushion: Dual-chamber cushion, 45 mm each side

Working Pressure: 18 MPa Test Pressure: 27 MPa Working Medium: Hydraulic Oil

Feature: Piston rod equipped with bellows-type flame-retardant dust cover; built-in displacement sensor for precise positioning

7. Suction Hood Hydraulic Cylinder UG1307R90/45-625

Bore: Ø125 mm Rod: Ø90 mm Stroke: 700 mm Cushion: Dual-chamber cushion, 45 mm each side

Working Pressure: 18 MPa Test Pressure: 27 MPa Working Medium: Hydraulic Oil

Feature: Piston rod equipped with bellows-type flame-retardant dust cover; built-in displacement sensor

8. Fume Hood Tilting Hydraulic Cylinder UYR2303Z200/110-960

Bore: Ø200 mm Rod: Ø110 mm Stroke: 960 mm Cushion: Dual-chamber cushion, 50 mm each side

Working Pressure: 15 MPa Test Pressure: 25 MPa Working Medium: Hydraulic Oil

Feature: Compact structure and quick response, ideal for high-temperature fume hood tilting operations