The Importance of Hydraulic Cylinder Synchronization in Industrial Systems

Hydraulic cylinder synchronization ensures coordinated movement across multiple actuators, a critical requirement for industrial machinery ranging from gantry cranes to forging presses. Modern hydraulic systems achieve positional accuracy within ±0.25mm through synchronized operation, preventing structural stress responsible for 23% of hydraulic system failures in heavy machinery (Fluid Power Research Group, 2023).

Purpose of Synchronizing Hydraulic Cylinder Movement in Heavy-Duty Systems

Proper synchronization eliminates differential forces that cause premature bearing wear and piston rod deflection. In bridge erection systems, unsynchronized cylinders create load imbalances exceeding 15% of rated capacity, leading to catastrophic racking forces. Synchronized flow control maintains uniform pressure gradients across all actuators, enabling precise parallel lifting of 500+ ton loads.

Challenges in Maintaining Stroke Accuracy Across Multi-Cylinder Setups

Three primary factors disrupt synchronization:

- Component wear (0.05mm seal degradation increases velocity mismatch by 12%)

- Thermal expansion variations (±0.1mm/10°C in steel components)

- Fluid compressibility differences under dynamic loads

These variables compound in 8+ cylinder configurations, requiring real-time compensation to maintain <1% stroke deviation.

Impact of Misalignment on System Efficiency and Equipment Lifespan

A 0.75mm synchronization error in press brake systems:

| Parameter | Impact |

|---|---|

| Energy Consumption | Increases 18-22% |

| Bearing Service Life | Reduces 40-60% |

| Hydraulic Fluid Degradation | Accelerates 3x |

Such misalignment costs manufacturers an average of $142,000 annually in unplanned downtime and component replacements (Industrial Hydraulics Report, 2024).

Hydraulic Distributors: Enabling Precision Flow Control for Synchronization

How Hydraulic Distributors Maintain Flow Uniformity for Near-Zero Error

Flow distributors in hydraulic systems create balanced flow by using specially designed splitting mechanisms that keep pressure differences between cylinders to a minimum. When pumps split their output into equal parts, the system can keep cylinder synchronization within about 1.5% accuracy across multiple cylinders, even when load conditions change back and forth. According to recent industry data from 2024, modern flow divider valves now incorporate dual path compensation features. These advanced valves automatically compensate for changes in fluid thickness and temperature variations, which means operators don't have to constantly monitor and adjust settings manually during operation.

- Pressure balancing: Maintains ±2 bar differential across parallel circuits

- Dynamic flow correction: Adjusts flow rates in 50ms intervals using real-time LVDT feedback

- Error cascading prevention: Isolation check valves prevent error accumulation in series configurations

Design Innovations in Flow-Splitting Manifolds for Multi-Cylinder Systems

The latest manifold designs use computational fluid dynamics (CFD) to create shapes that cut down on turbulence problems. We're seeing around a 40% reduction in turbulence compared to older models. For pressure compensated flow control valves, manufacturers have started incorporating bypass channels as standard features. These channels handle extra flow without messing with the main pressure levels in the system. What does this mean practically? Systems can maintain very consistent flow rates now. The variance between different points is typically no more than 1.2%. Even when running eight cylinders simultaneously at those high 350 bar pressures, the system still maintains pretty good uniformity throughout.

Case Study: Synchronization in Press Machines Using Closed-Loop Distributor Control

In some 2,500 ton stamping presses recently put into action, they managed to get pretty impressive results with just 0.8 mm of positional error when running four big 400 mm bore cylinders at around 60 strokes per minute. What made this work so well was combining those electrohydraulic proportional valves with some fancy non contact position sensors. Over the course of full day production runs, the system barely drifted out of sync at all – talking about less than 0.05% drift which is basically nothing in industry terms. The setup also knocked down those pesky hydraulic shock problems by nearly three quarters, which is huge. And here's another good part: even with all these improvements, the machines still kept their energy efficiency high at about 92% throughout different operating conditions. That kind of performance makes a real difference on the factory floor.

Sensor Integration and Real-Time Monitoring in Hydraulic Cylinders

Position-sensing (smart) cylinders with magnetostrictive feedback for precise synchronization

In today's factories, many automated processes depend on special hydraulic cylinders equipped with magnetostrictive technology that keeps synchronization errors almost non-existent. What makes these so-called smart cylinders stand out is their ability to monitor piston positions down to about half a thousandth of a millimeter accuracy. They constantly send this information back to central control systems in real time. The result? Machines work together much better when multiple cylinders are involved, whether it's in heavy stamping operations or complex robotic assembly lines. Over long production runs, this kind of precision helps prevent those annoying little errors from building up over time that can really mess with quality control.

Comparison of Hall effect and magnetostrictive sensor technologies in hydraulic applications

When picking out sensor tech, there's always that balancing act between how accurate it needs to be versus how tough it has to last. Hall effect sensors tend to be cheaper at first glance and give decent accuracy around plus or minus 0.1mm. These work pretty well for simple jobs where things don't shake too much. Then we have those magnetostrictive options which cost about 20 to 30 percent more but deliver really fine precision down to the micron level. What makes these stand out is their ability to keep performing even when exposed to pressures over 300 bar in hydraulic systems. The big advantage here is that they just don't care about dirty hydraulic fluids getting into them something that ruins optical sensors and gives Hall effect models fits. That's why factories dealing with heavy industrial stuff like steel mills or rock crushers often go for magnetostrictive sensors despite the extra cash needed upfront.

Automatic resynchronization triggered by real-time parameter deviations

Systems kick into action when there's a shift in position or load beyond what's been set as normal limits, usually around half a percent of the total stroke length. These monitoring setups don't wait for someone to notice something's wrong before taking steps to fix it. Take those big machines used in steel coiling operations for instance. When sensors detect that cylinders start slipping, they trigger a quick reset process within just 20 milliseconds flat, which stops expensive material damage from happening. What makes all this possible is the constant stream of information about pressure levels, temperatures, and where everything actually is at any given moment. All these factors get fed into the system so it can tweak those flow control valves on the fly throughout the hydraulic network.

Reliability of sensor-based systems in high-vibration industrial environments

Sensor enclosures rated IP69K and built to withstand MIL-STD vibrations across frequencies from 5 to 2000 Hz keep systems running at over 99.5% availability even when mounted on rough terrain machinery or inside tunnel boring equipment. These designs incorporate backup data routes and wiring protected against electromagnetic interference to maintain signal quality. The sensors themselves sit on mounts that can handle impacts up to 50g force without failing. According to field testing, vibration-related problems fall under 0.1% per year when installations follow manufacturer guidelines. This kind of reliability proves just how solid contemporary sensor technology has become for operation in harsh environments where failure isn't an option.

Electronic Control Systems: PID Optimization and Adaptive Feedback Loops

Electronic feedback systems for synchronization under dynamic loads

When dealing with multiple hydraulic cylinders under changing loads, electronic feedback systems really shine at keeping everything synchronized properly. The system gets real time info from those position sensors, lets the controller check how fast each cylinder is extending, then makes tiny adjustments to the flow distributor almost instantly. What we're talking about here is closed loop control that actually works around those uneven forces we see in things like injection molding machines or when operating crane booms. These systems manage to keep all the cylinders aligned pretty closely together even when there are sudden changes in load. The result? Less chance of parts getting stuck together and significantly reduced wear on bearings over time.

PID control optimization for improved response stability in servo-hydraulic loops

PID controller tuning minimizes phase lag and overshoot in hydraulic cylinder synchronization loops. Optimizing proportional (Kp), integral (Ki), and derivative (Kd) gains achieves:

- Reduced oscillation during speed transitions

- Steady-state error below 0.1% full stroke

- Settling times under 100ms

Proper tuning prevents gain-induced instability while handling the nonlinear friction characteristics inherent in hydraulic cylinder seals and rod guides.

Real-time parameter tuning to maintain control under external disturbances

Self-tuning algorithms continuously adjust PID parameters when external disruptions like sudden load shifts or temperature-induced viscosity changes occur. Flow control valves receive updated commands within 25ms of disturbance detection, maintaining synchronization accuracy. This autonomous recalibration compensates for:

- Supply pressure fluctuations up to 15%

- Hydraulic fluid viscosity variations

- Seal friction changes during temperature transitions

Dynamic response enhancement through adaptive gain scheduling

Adaptive gain scheduling works by changing controller settings according to what's happening in the system, which helps keep those hydraulic cylinders working together properly. Research from around 2023 showed that these adjustable PID controllers settle down about two thirds quicker than regular fixed ones when dealing with speed changes while loads vary. The whole point is to get almost no position errors even during fast production runs, all without someone needing to tweak things manually every time there's a problem.

Advanced Control Strategies and Custom Solutions for Multi-Cylinder Synchronization

Nonlinear Control Challenges in Complex Multi-Cylinder Hydraulic Networks

Hydraulic systems today need their cylinders to stay synchronized within about half a millimeter when working with networks containing over ten actuators. This becomes really challenging because of things like fluid compression, where each 100 bar increase in pressure actually reduces volume by around 1.5%, plus all those unpredictable load changes that happen during operation. According to industry data from 2023, nearly half (that's 42%) of synchronization problems seen in press brake applications come from uneven pressure waves running through complicated manifold setups rather than just plain old mechanical wear issues as many might assume.

Integrating Fuzzy Logic and Model Predictive Control with Traditional PID Systems

Hybrid control architectures combining PID systems with fuzzy logic reduce synchronization errors by 63% in scenarios with undefined load patterns. For example, model predictive control (MPC) pre-calculates flow requirements 50 ms ahead of actuator movement—critical for systems handling asymmetric payloads exceeding 250 tons.

Case Study: AI-Assisted Synchronization in Automated Stamping Lines

Automotive stamping lines using AI-assisted synchronization achieved 99.4% positional coherence across 16-cylinder setups through live die deflection analysis. Machine learning algorithms correlate force and temperature data from hydraulic cylinders with positional drift patterns, enabling automatic valve timing adjustments every 17 ms without human intervention.

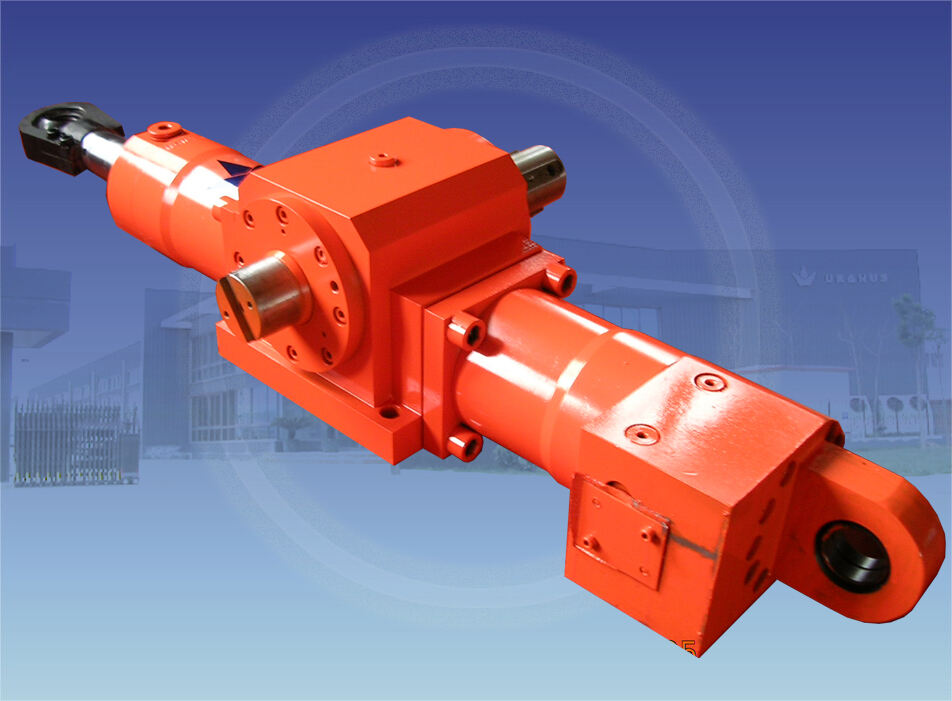

Custom-Built Hydraulic Cylinders with Factory-Integrated Sensors for Superior Performance

Integrated magnetostrictive sensors in custom cylinders eliminate 78% of calibration errors observed in retrofitted systems. These units embed ISO 4400-certified transducers directly into piston rods, providing ±0.05 mm repeatability even in environments with 15 g vibration loads—meeting the stringent requirements of semiconductor wafer handling robots.

FAQ

What is hydraulic cylinder synchronization?

Hydraulic cylinder synchronization is the process of coordinating movement across multiple actuators in a hydraulic system to ensure they move in harmony with each other. This prevents structural stress and enhances system efficiency.

Why is synchronization important in industrial systems?

Synchronization in industrial systems is important to prevent differential forces that can cause premature equipment wear and reduce energy efficiency. It allows for precise and coordinated lifting or movement of heavy loads without causing imbalances or failures.

What are the challenges in maintaining hydraulic cylinder synchronization?

Challenges include component wear, thermal expansion, and fluid compressibility differences. These factors can disrupt synchronization and require real-time compensation to maintain accuracy.

How do hydraulic distributors help in synchronization?

Hydraulic distributors help maintain flow uniformity by using splitting mechanisms to balance flow and pressure differences across actuators, ensuring near-zero synchronization errors.

What role do sensors play in hydraulic systems?

Sensors with feedback systems enable real-time monitoring and adjustments in hydraulic systems, improving precision and preventing errors in synchronization even in harsh industrial environments.

Table of Contents

- The Importance of Hydraulic Cylinder Synchronization in Industrial Systems

- Hydraulic Distributors: Enabling Precision Flow Control for Synchronization

- Electronic Control Systems: PID Optimization and Adaptive Feedback Loops

-

Advanced Control Strategies and Custom Solutions for Multi-Cylinder Synchronization

- Nonlinear Control Challenges in Complex Multi-Cylinder Hydraulic Networks

- Integrating Fuzzy Logic and Model Predictive Control with Traditional PID Systems

- Case Study: AI-Assisted Synchronization in Automated Stamping Lines

- Custom-Built Hydraulic Cylinders with Factory-Integrated Sensors for Superior Performance

- FAQ