・Dubbele oscillatiemodi: Ondersteunt sinusvormige en niet-sinusvormige golfvormen

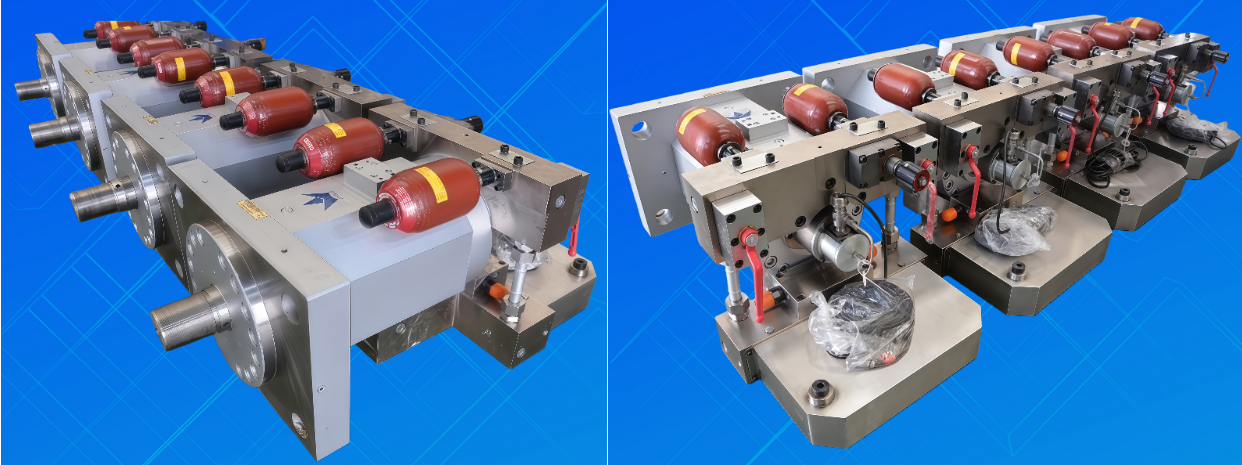

・Onafhankelijke straalbediening: Meerstralige CCM's met parameterafstelling per straal

・Slimme connectiviteit: MES/expertsysteemintegratie voor afstandsmonitoring, diagnose, voorspellend onderhoud

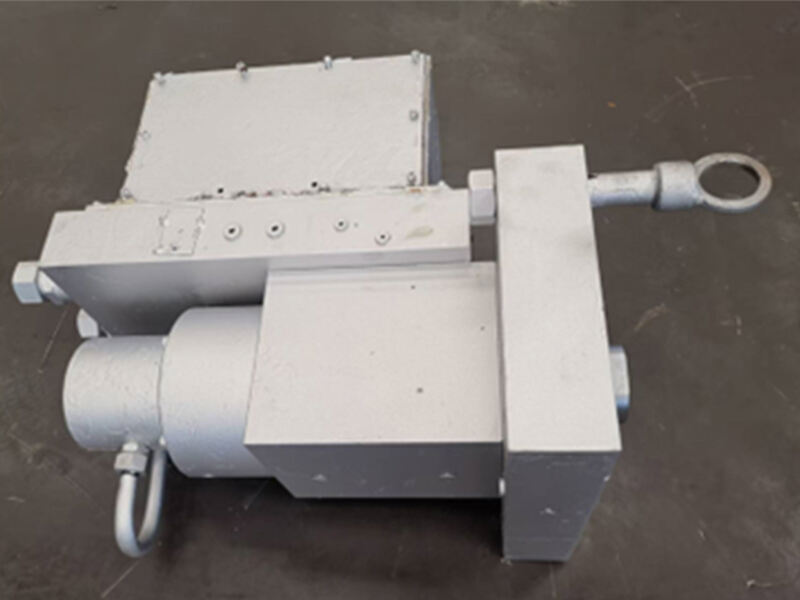

・Robuust en betrouwbaar: Lange levensduur, laag onderhoud, stabiel onder extreme omstandigheden

Voordelen

✅ Verbeterde oppervlaktekwaliteit, verminderde oscillatieafdrukken

✅ Hogere opbrengst en bedrijfsefficiëntie

✅ Ondersteunt hoge giet snelheid, verhoogde productiviteit

✅ Energiebesparing en lagere bedrijfskosten

✅ Eenvoudige installatie, bediening en onderhoud

Toepassingen

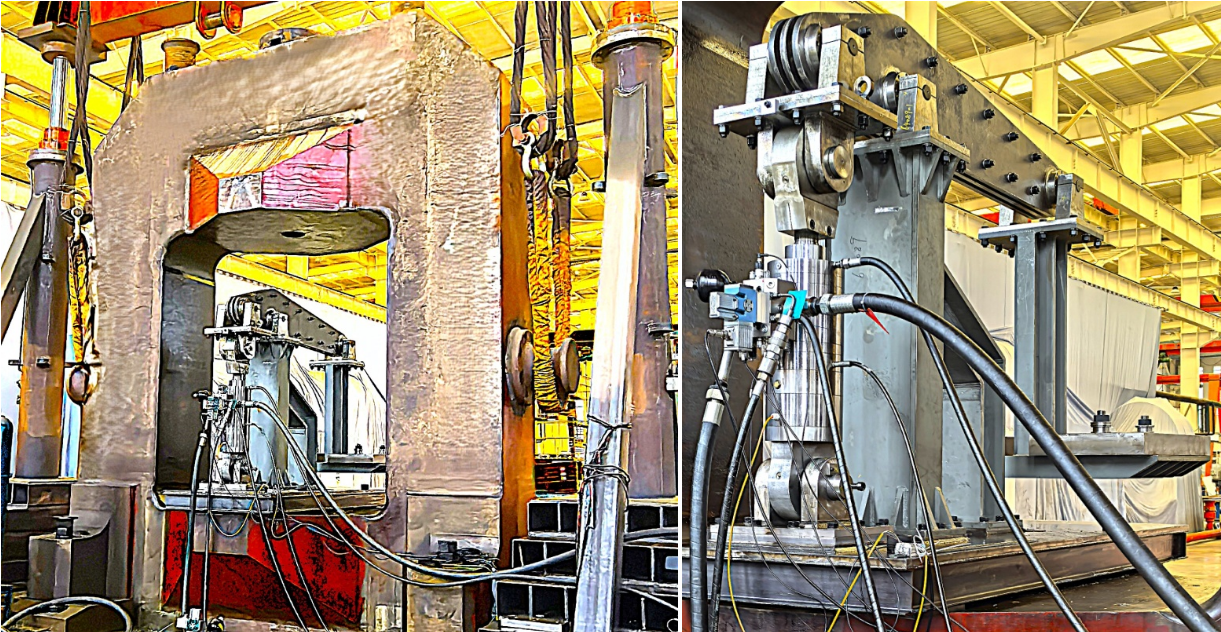

Veelvuldig gebruikt in hoogrendements billet-, bloom- en plaatgietmachines voor zowel staal als non-ferro metalen.

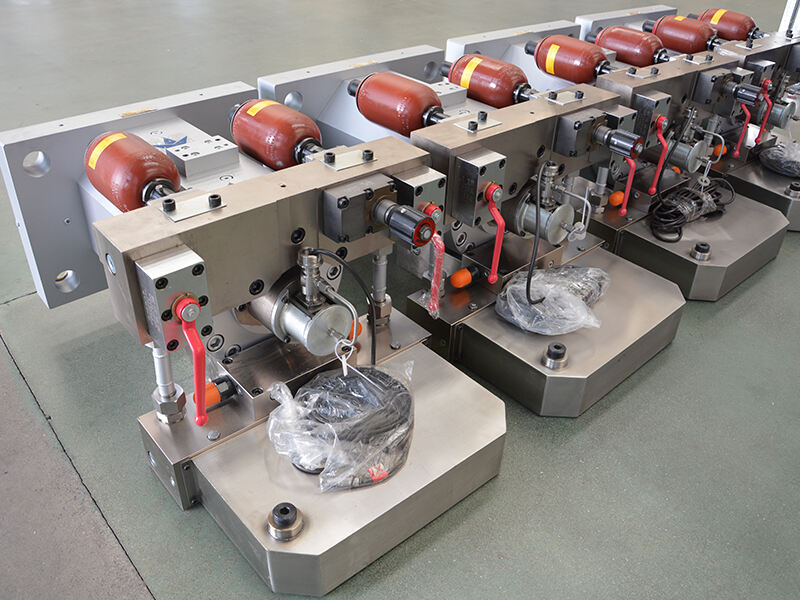

Testen en verificatie

Onze eigen testbanken simuleren volledige belastingomstandigheden en bieden aangepaste trillingstests met volledige rapportages inclusief datalogging en golfvormanalyse.

Waarom Ons Kiezen

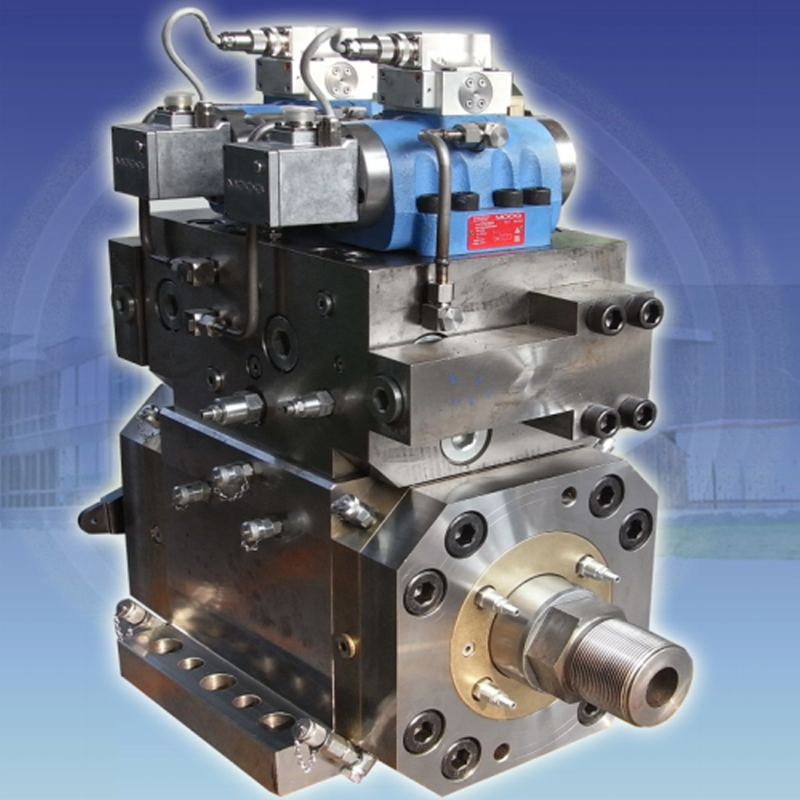

Met meer dan 20 jaar ervaring heeft Uranus meer dan 20 modellen ontwikkeld en honderden servotrilsystemen wereldwijd geleverd — vertrouwd om innovatie, betrouwbaarheid en prestaties.

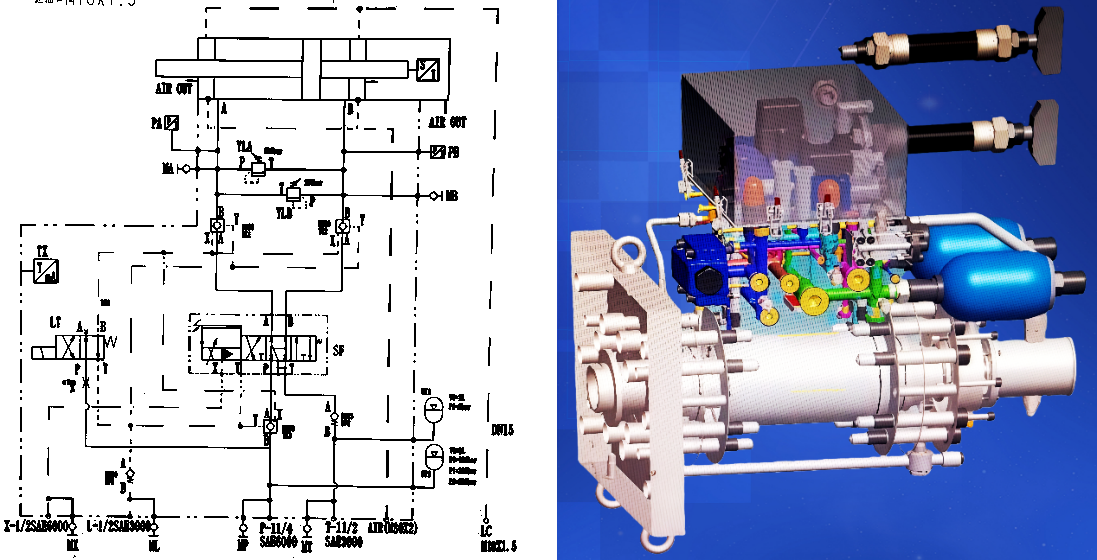

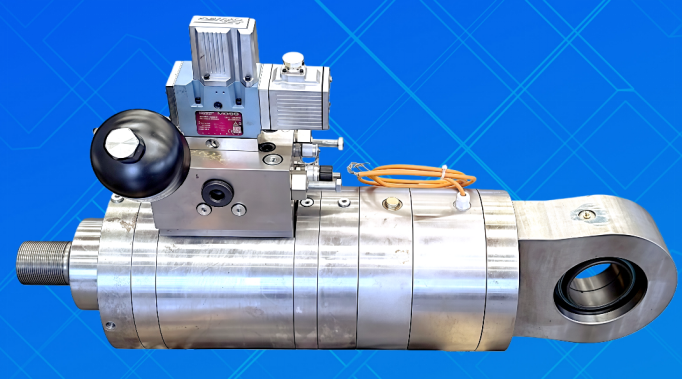

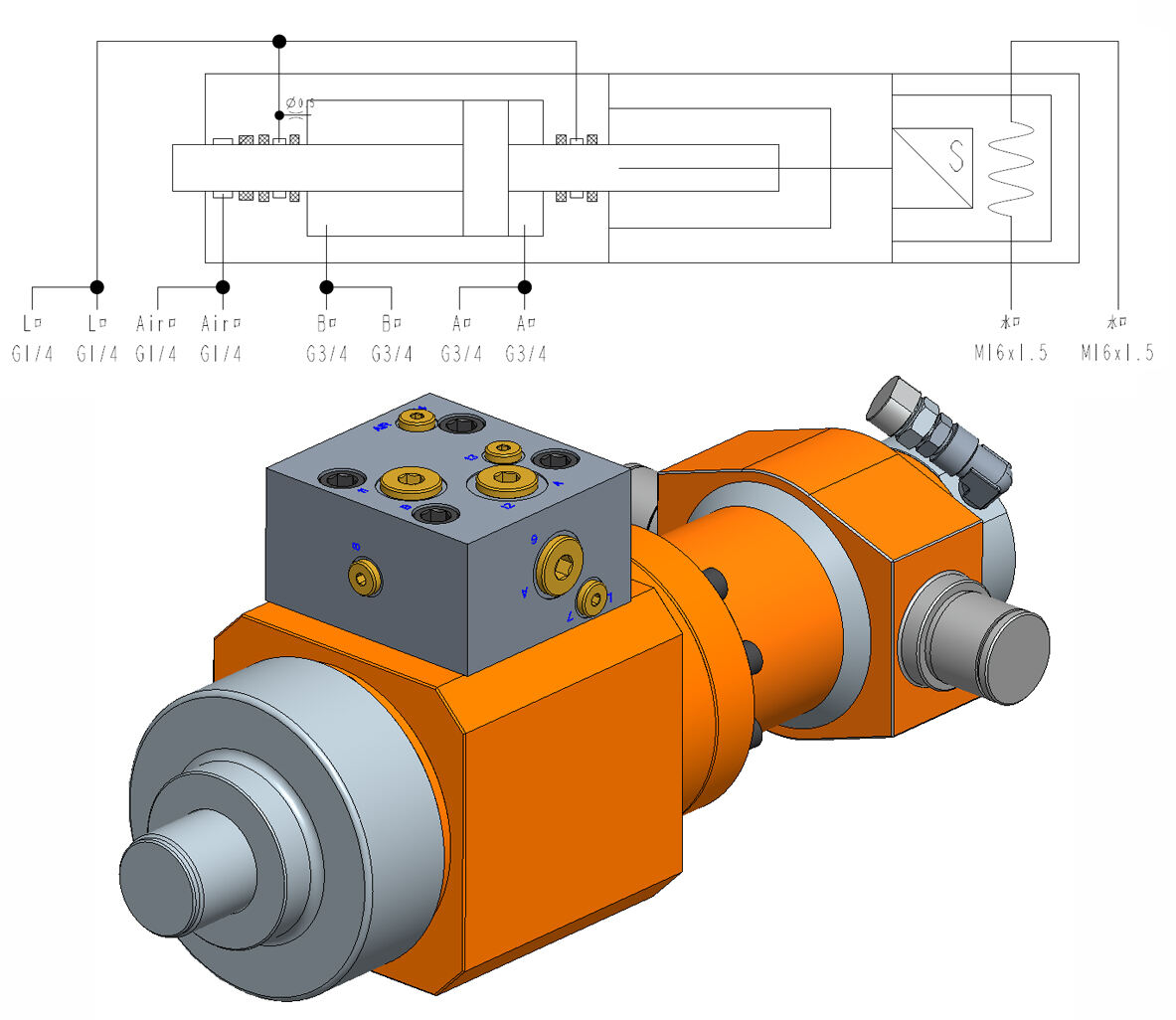

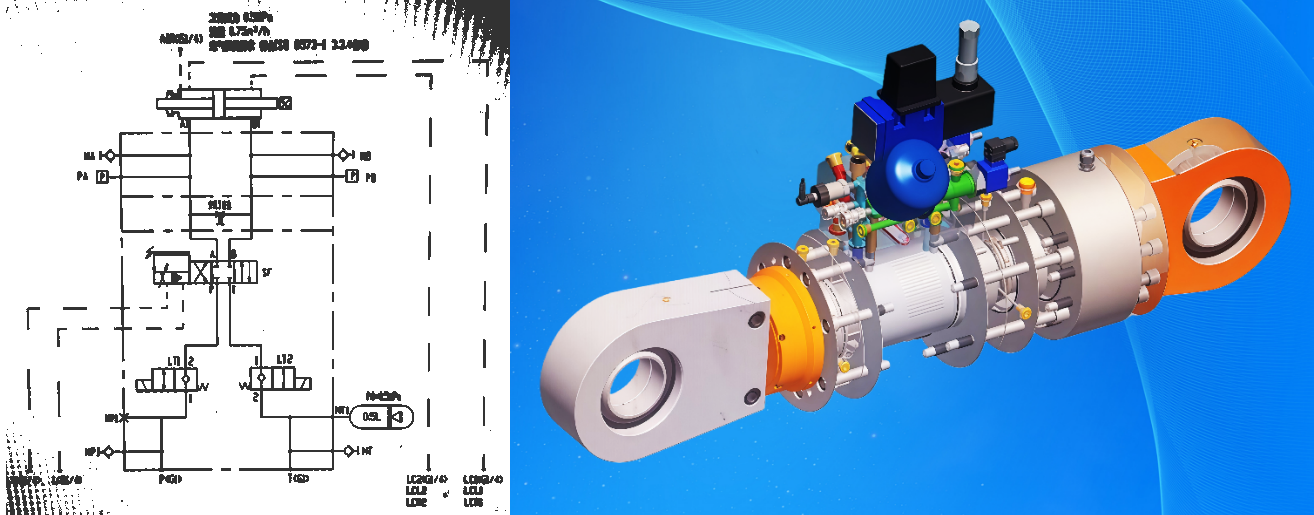

De vormoscillerende servo-cilinder maakt het mogelijk voor de vorm in de productielijn van plaatstaalcontinuegietsel om een boogbeweging uit te voeren langs de straal van het continuegietsel. Deze beweging wordt bepaald door specifieke amplitude, frequentie en golfvormdeflectiekenmerken, wat de op-en-neer oscillatie van de vorm faciliteert. De gecontroleerde sequentiële trilling zorgt voor smering en voorkomt vastplakken tussen het gegoten staal en de vormwand.

De Uranus vormoscillerende cilinder maakt gebruik van elektro-hydraulische directe aandrijvingstechnologie, wat zowel sinusoïdale als niet-sinusoïdale vibratiefuncties mogelijk maakt. Dit systeem biedt verschillende voordelen, waaronder intelligente bediening, hoge frequentie, hoge precisie, weinig onderhoud, een lange levensduur en hoge betrouwbaarheid. Het ontwerp is eenvoudig en kosteneffectief, met gemakkelijke installatie en laag onderhoud. Het systeem verhoogt de gietvaart, verhoogt de uitkomst van de gietmachine, verlaagt de energieverbruik en exploitatiekosten terwijl het zowel productiefiteit als productkwaliteit verbetert.

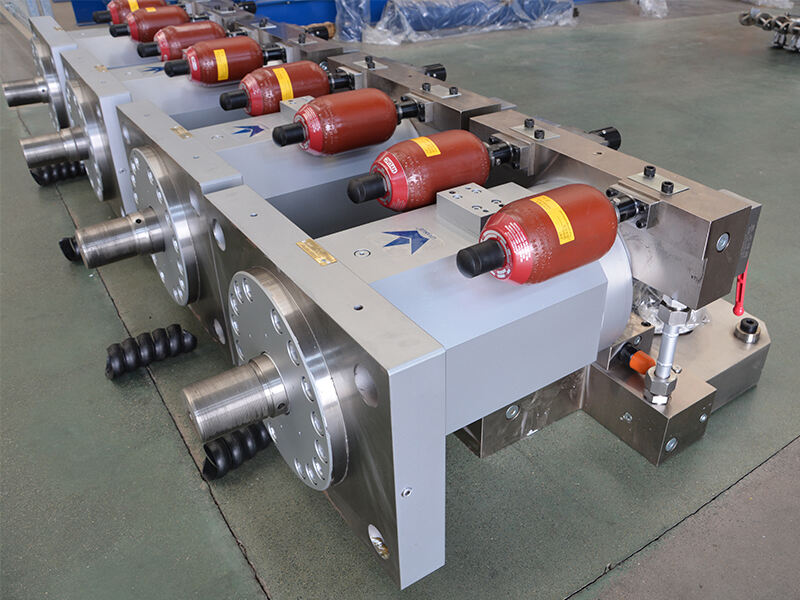

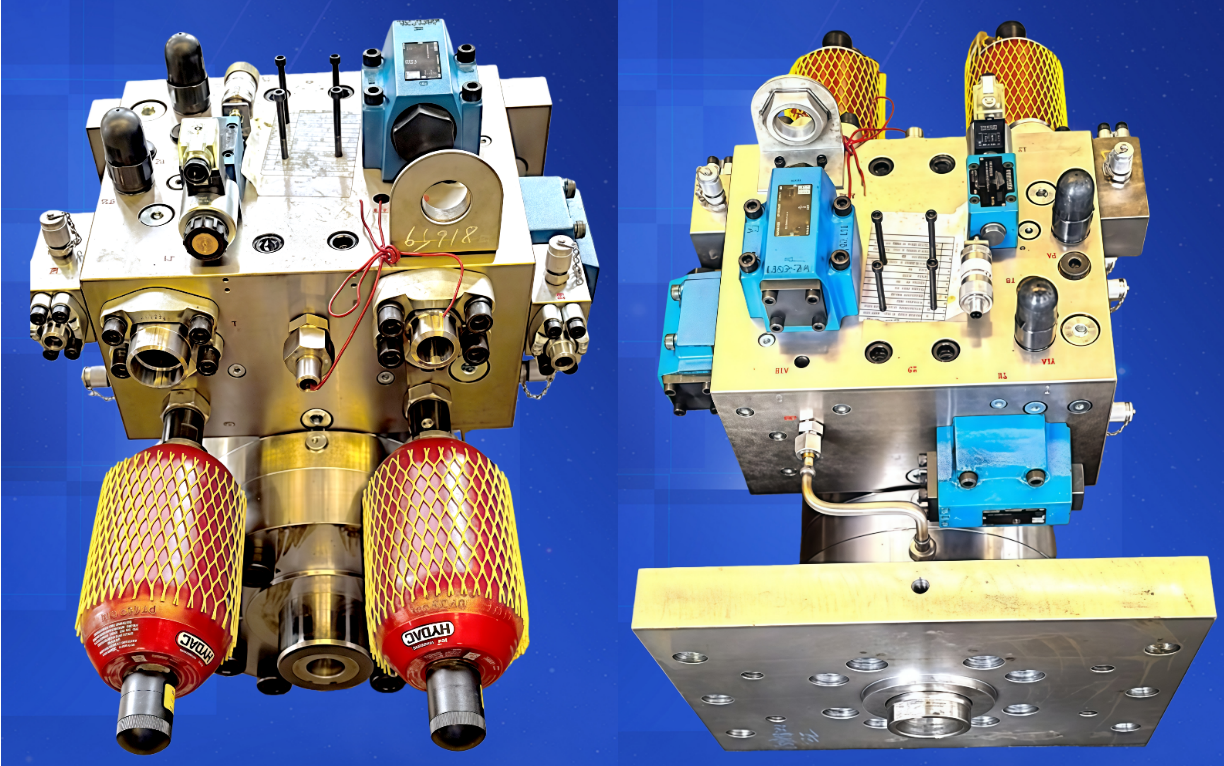

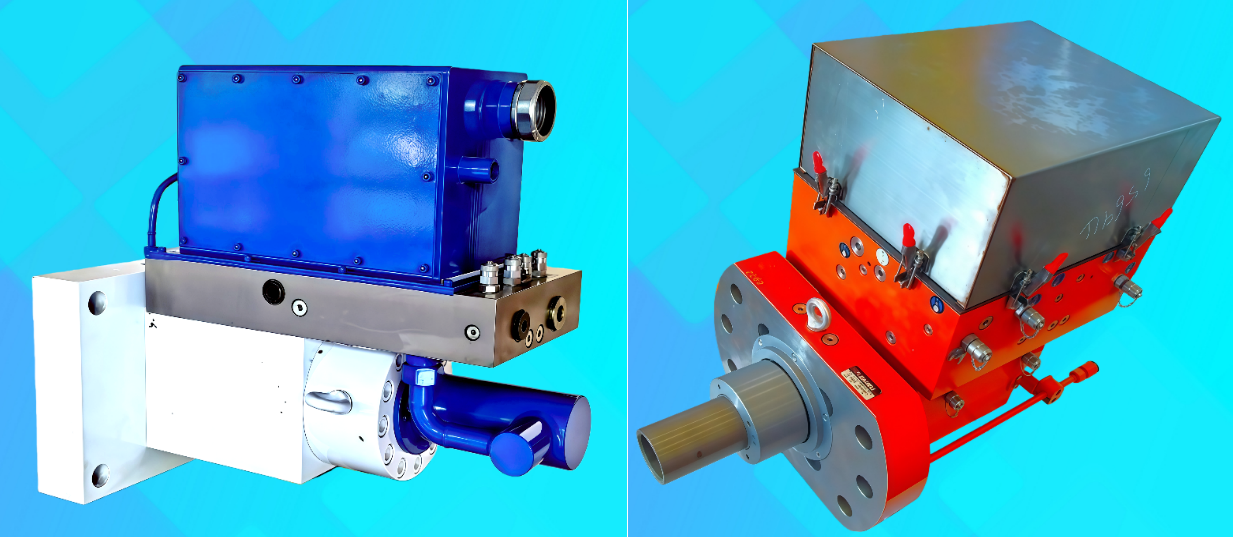

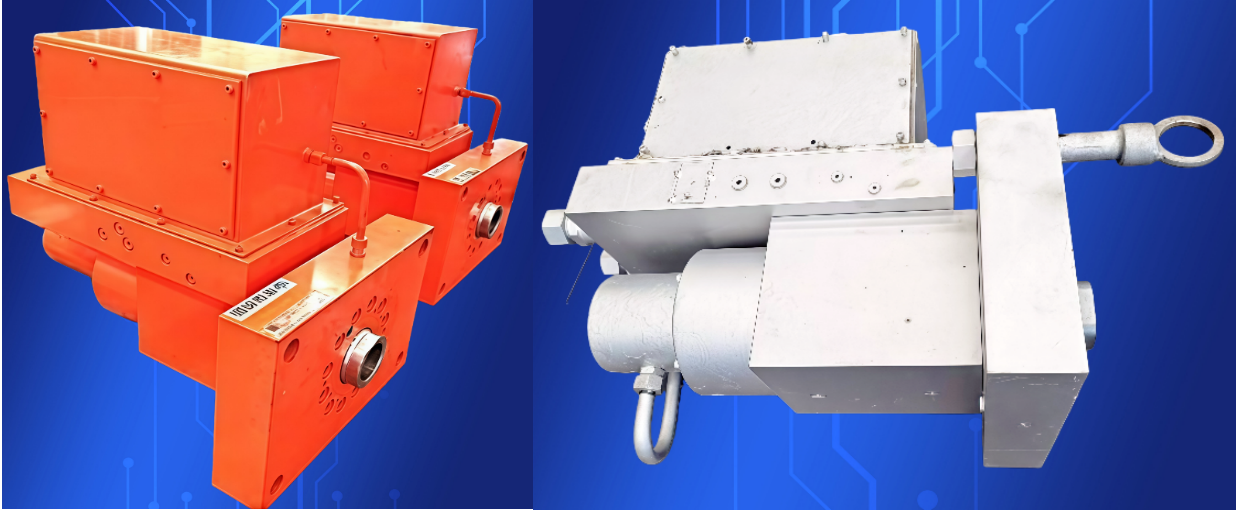

Sinds meer dan 20 jaar hebben we honderden vormoscillerende cilinders geproduceerd in meer dan 20 verschillende typen. Hieronder staan enkele voorbeelden van onze vormoscillerende cilinders:

Typische modellen & specificaties.

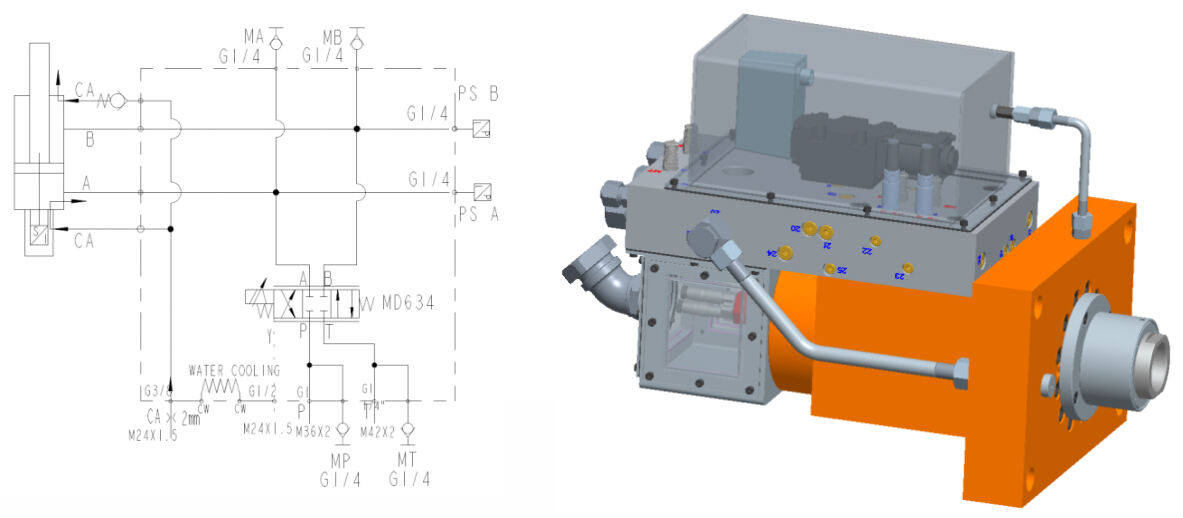

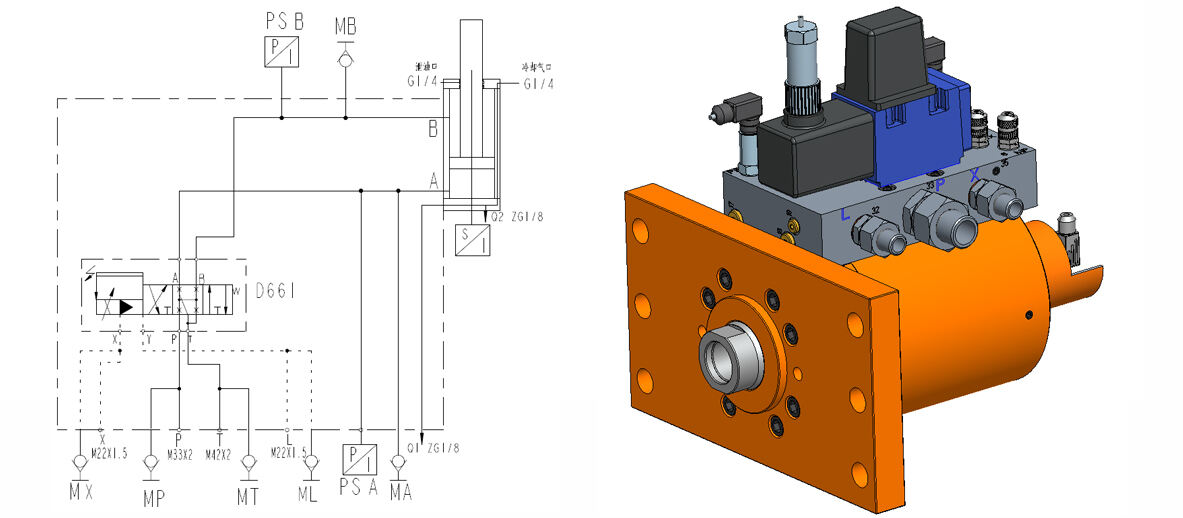

1.1、Model: USYR2501R140/90-50LJHS+FK

・Boring 140 mm; Zuigerstang 90 mm; Slag 50 mm

・Druk: Bedrijf 25 MPa; Test 31,5 MPa

・Medium: Water-glycol; Afdichting: FKM

・Ingebouwde verplaatsingssensor; servokleppenblok

・Servoklep: 75 L/min, max 350 bar; 24V, ±10 mA, feedback 4–20 mA

・Validatie: Belasting 4500 kg, trilling 193–325 OPM, nauwkeurigheid binnen ±0,02 mm

・Dynamische kenmerken: 25% van maximale signaalwaarde 60 Hz (9 hellinglijn)

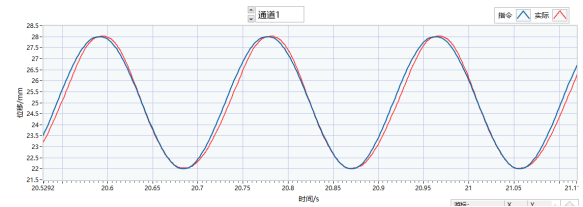

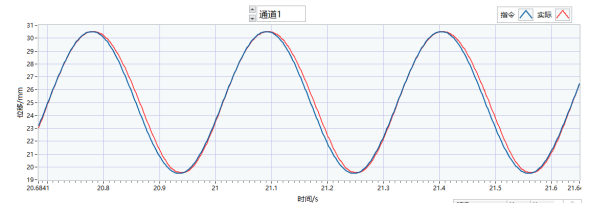

Belastingtestcurves van de servo-tril-hydraulische cilinder voor kristallizer (belasting: 4500 kg)

1)Totale slag: 6 mm (±3 mm) ; Trilfrequentie: 325 OPM;

Nauwkeurigheid: ±0,025 ~ -0,02 mm. Zie onderstaande afbeelding.

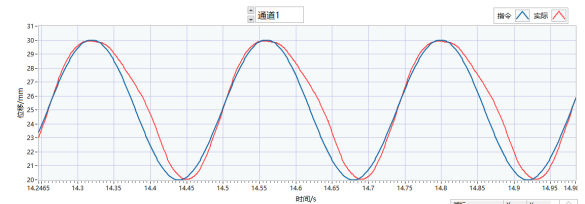

2)Totale slag: 10 mm (±5 mm) ; Trilfrequentie: 250 OPM;

Nauwkeurigheid: ±0,07 ~ -0,02 mm. Zie onderstaande afbeelding

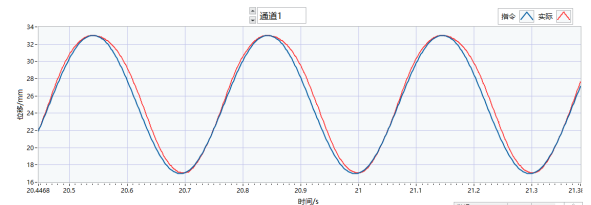

3) Totale slag: 16 mm (±8 mm); Oscilleringsfrequentie: 200 OPM;

Nauwkeurigheid: ±0,015 ~ -0,05 mm. Zie de onderstaande afbeelding.

4) Totale slag: 11 mm (±5,5 mm); Oscilleringsfrequentie: 193 OPM;

Nauwkeurigheid: ±0,015 ~ -0,05 mm. Zie de onderstaande afbeelding.

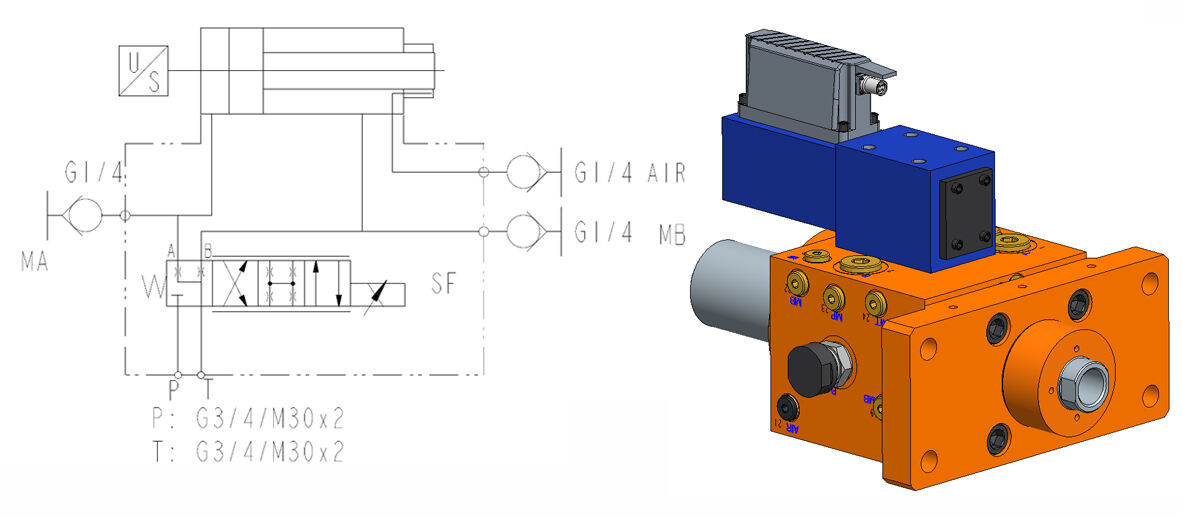

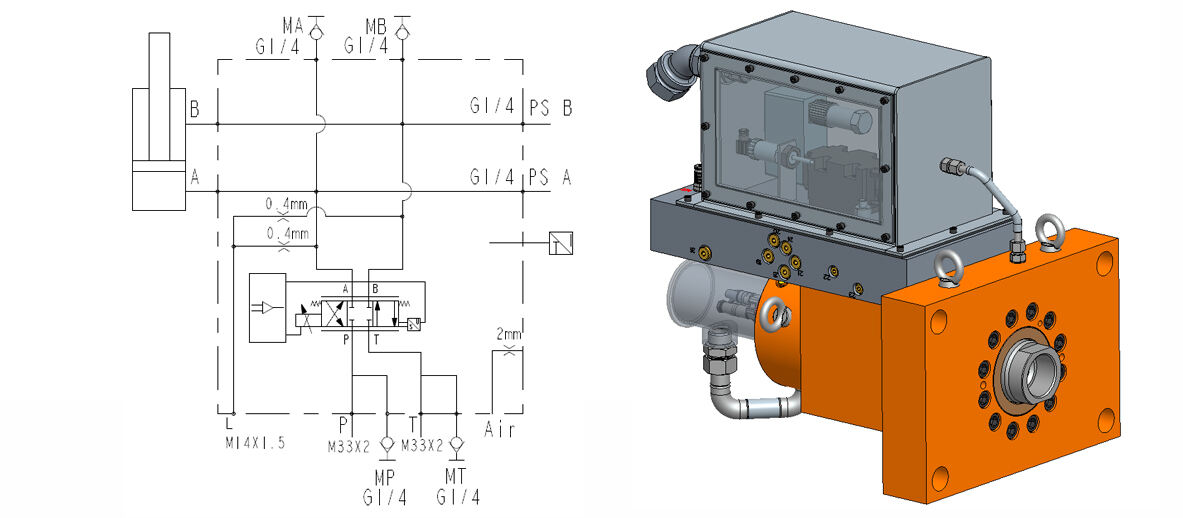

2, Model: USYR2501R160/90-50LJHS+FK

・Cilinderdiameter 160 mm; Zuigerstang 90 mm; Slag 50 mm

・Druk: Bedrijf 25 MPa; Test 31,5 MPa

・Medium: Vetester; Temperatuur −10℃~+80℃

・Ingebouwde verplaatsingssensor;