・दोहरे दोलन मोड: साइनुसॉइडल और गैर-साइनुसॉइडल तरंग रूप का समर्थन करता है

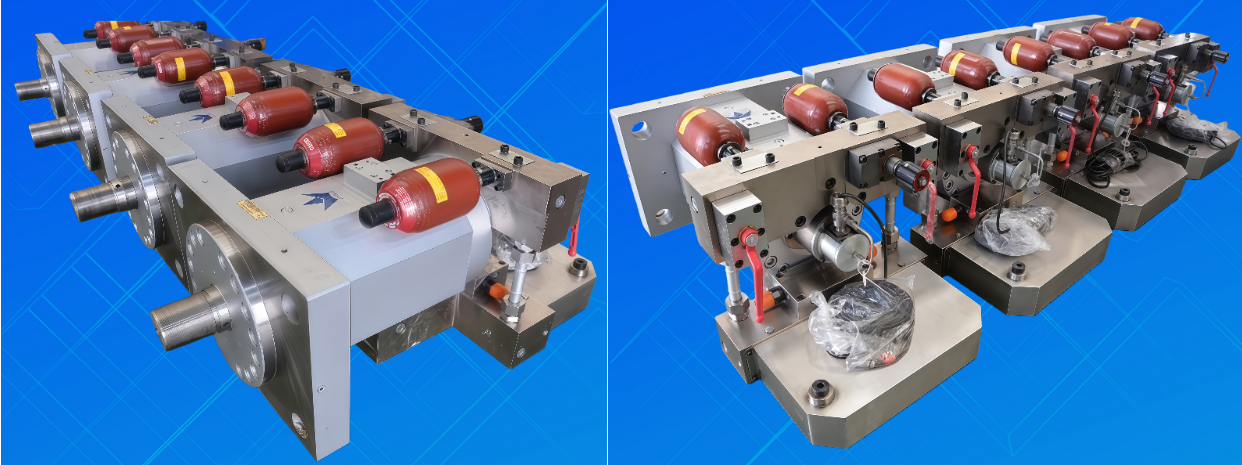

・स्वतंत्र स्ट्रैंड नियंत्रण: प्रति-स्ट्रैंड पैरामीटर ट्यूनिंग के साथ बहु-स्ट्रैंड सीसीएम

・स्मार्ट कनेक्टिविटी: दूरस्थ निगरानी, निदान, भविष्यकथन रखरखाव के लिए एमईएस/एक्सपर्ट सिस्टम एकीकरण

・मजबूत और विश्वसनीय: लंबी सेवा आयु, कम रखरखाव, कठोर परिस्थितियों में स्थिर

लाभ

✅ सुधारित सतह की गुणवत्ता, दोलन चिह्नों में कमी

✅ उच्च उपज और संचालन दक्षता

✅ उच्च ढलाई गति का समर्थन करता है, उत्पादकता में वृद्धि

✅ ऊर्जा बचत और कम संचालन लागत

✅ स्थापना, संचालन और रखरखाव में आसानी

अनुप्रयोग

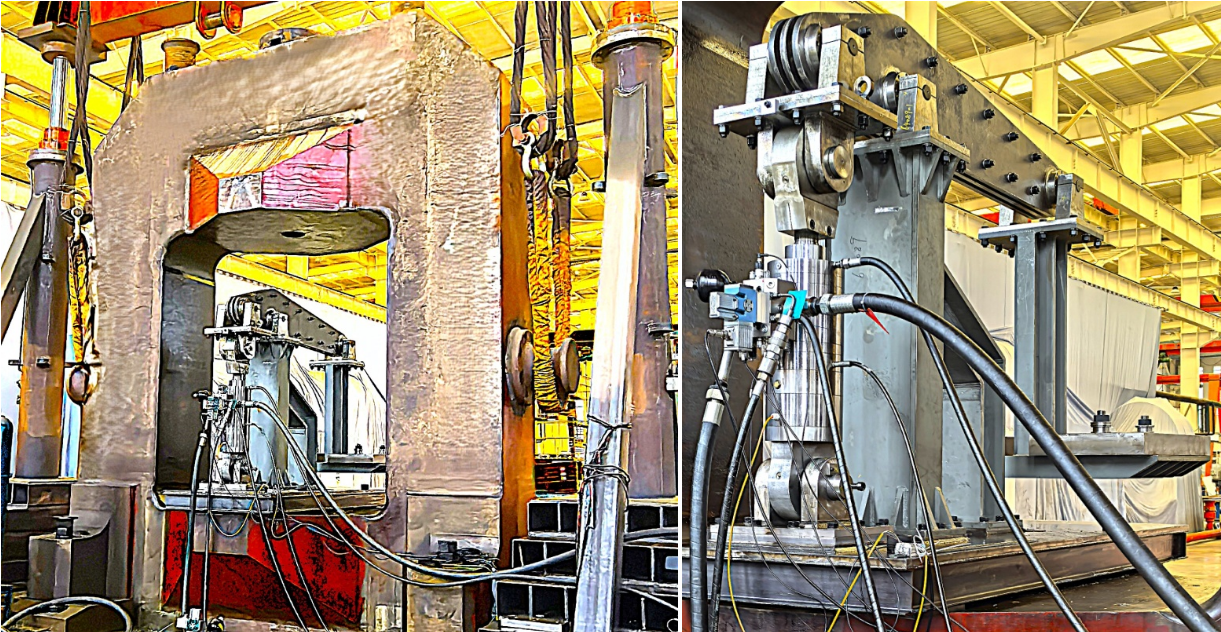

इसका व्यापक उपयोग इस्पात और गैर-लौह धातुओं दोनों के उच्च दक्षता वाले बिलेट, ब्लूम और स्लैब निरंतर ढलाई मशीनों में किया जाता है।

परीक्षण एवं सत्यापन

हमारे आंतरिक परीक्षण मेज पूर्ण भार की स्थिति का अनुकरण करते हैं और अनुकूलित कंपन परीक्षण डेटा लॉगिंग और वेवफॉर्म विश्लेषण सहित पूर्ण रिपोर्ट के साथ प्रदान करते हैं।

हमें क्यों चुनें

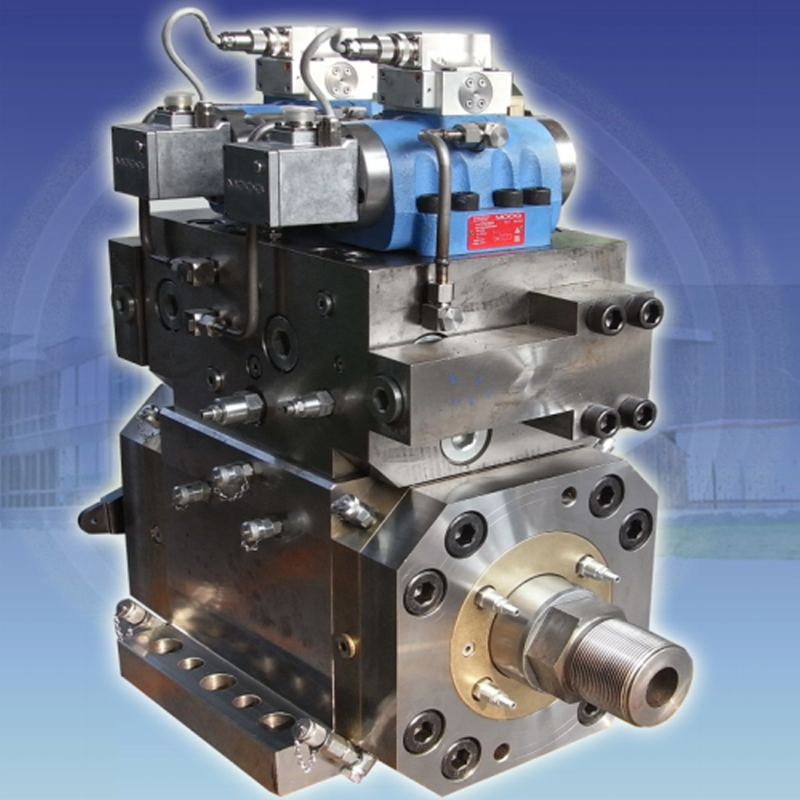

20+ वर्षों की विशेषज्ञता के साथ, यूरेनस ने दुनिया भर में सैकड़ों सर्वो दोलन प्रणालियों के साथ 20 से अधिक मॉडल विकसित किए हैं— नवाचार, विश्वसनीयता और प्रदर्शन के लिए विश्वसनीय।

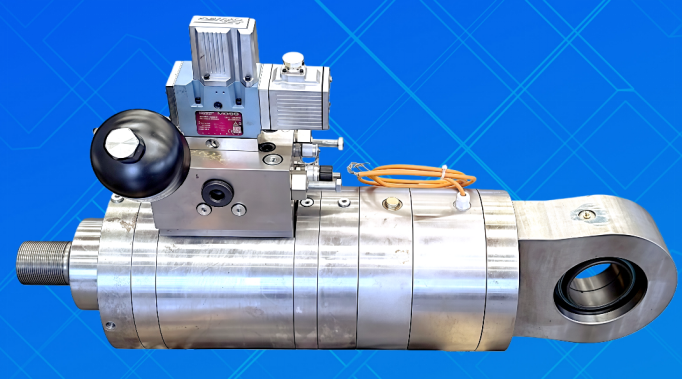

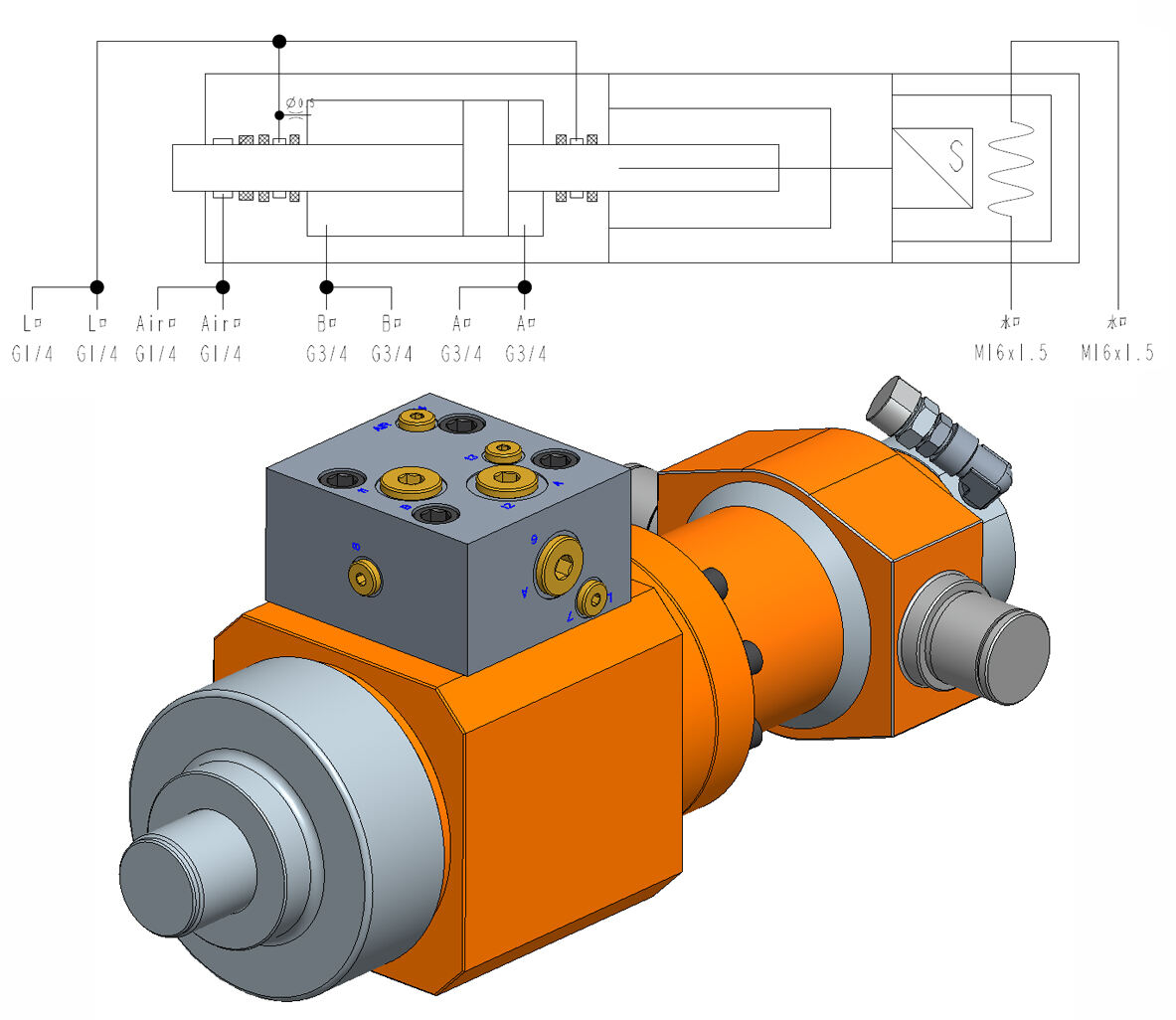

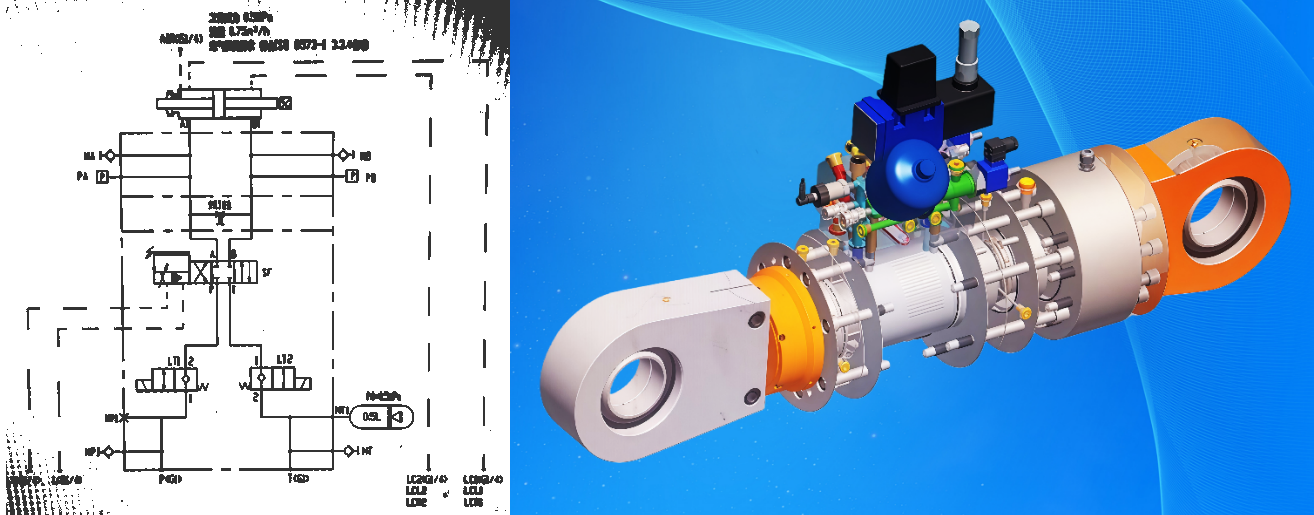

मोल्ड ऑसिलेटिंग सर्वो सिलिंडर स्लैब कंटीन्युअस कास्टिंग उत्पादन लाइन में मोल्ड को कंटीन्युअस कास्टिंग मशीन की त्रिज्या के साथ चाप गति करने की सुविधा प्रदान करता है। यह गति विशेष अम्प्लीट्यूड, आवृत्ति और तरंग रूप विक्षेपण विशेषताओं से नियंत्रित होती है, जिससे मोल्ड की ऊपर-नीचे ऑसिलेशन सुगम होती है। नियंत्रित क्रमबद्ध विभवन चालकता को सुनिश्चित करता है और कास्टिंग स्टील और मोल्ड दीवार के बीच चिपकाव को रोकता है।

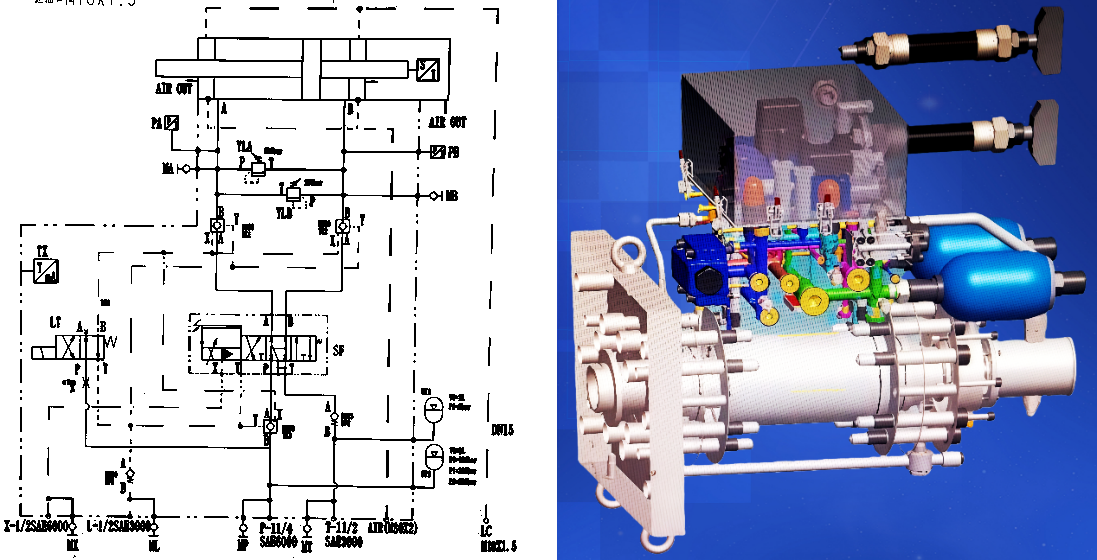

यूरेनस मोल्ड ऑसिलेटिंग सिलिंडर इलेक्ट्रो-हाइड्रॉलिक डायरेक्ट ड्राइव तकनीक का उपयोग करता है, जिससे साइनसोइडल और गैर-साइनसोइडल विब्रेशन कार्य को सक्षम किया जाता है। यह प्रणाली कई फायदों की पेशकश करती है, जिसमें बुद्धिमान संचालन, उच्च आवृत्ति, उच्च सटीकता, कम रखरखाव, लंबी सेवा जीवन और उच्च विश्वसनीयता शामिल है। इसका डिज़ाइन सरल और लागत-प्रभावी है, जिसमें आसान स्थापना और कम रखरखाव होता है। प्रणाली ढालने की गति को बढ़ाती है, ढालने वाली मशीन के उत्पादन को बढ़ाती है, और ऊर्जा खपत और संचालन लागत को कम करती है, जबकि उत्पादन की दक्षता और उत्पाद की गुणवत्ता में सुधार करती है।

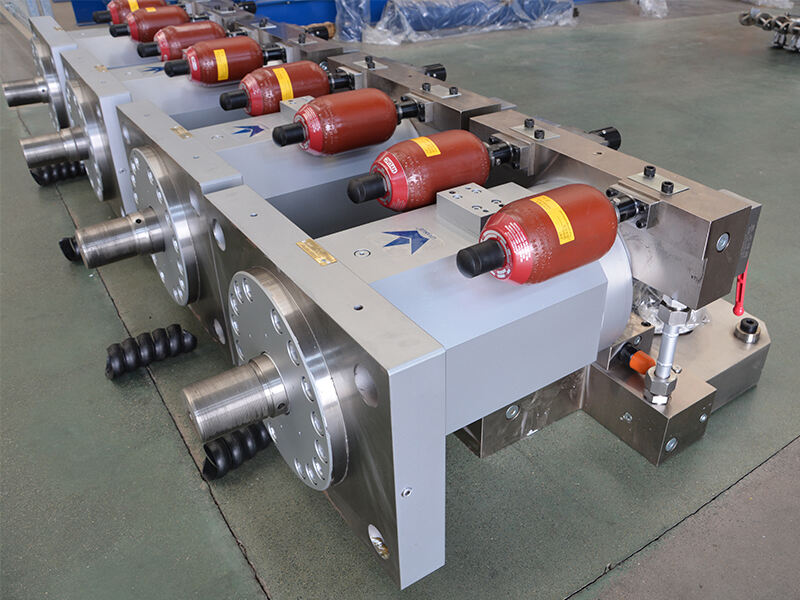

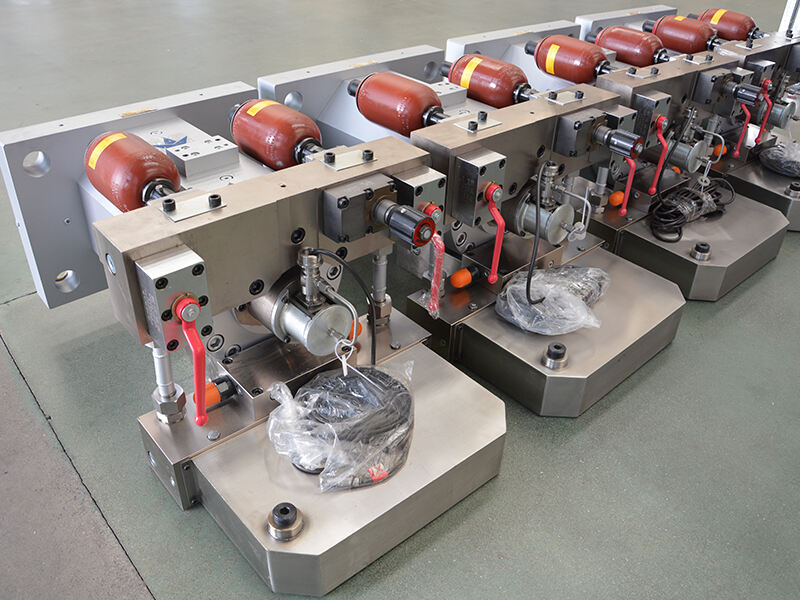

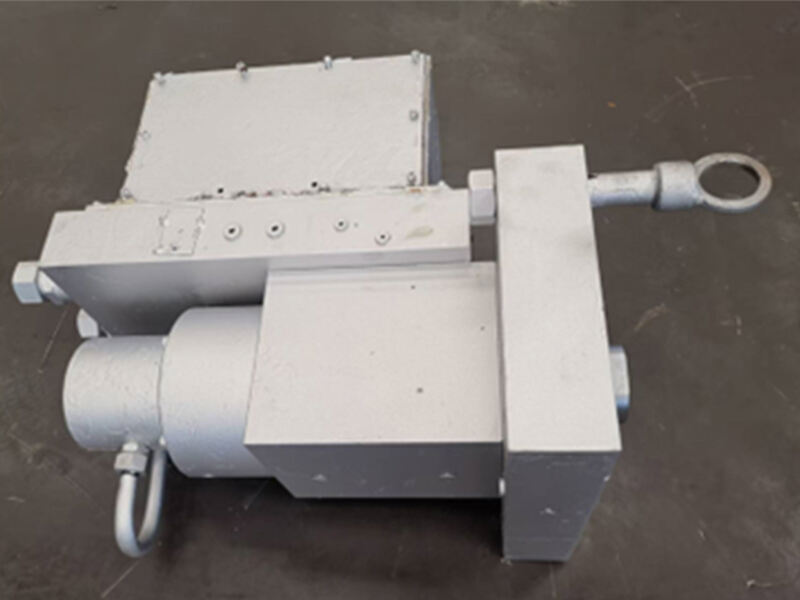

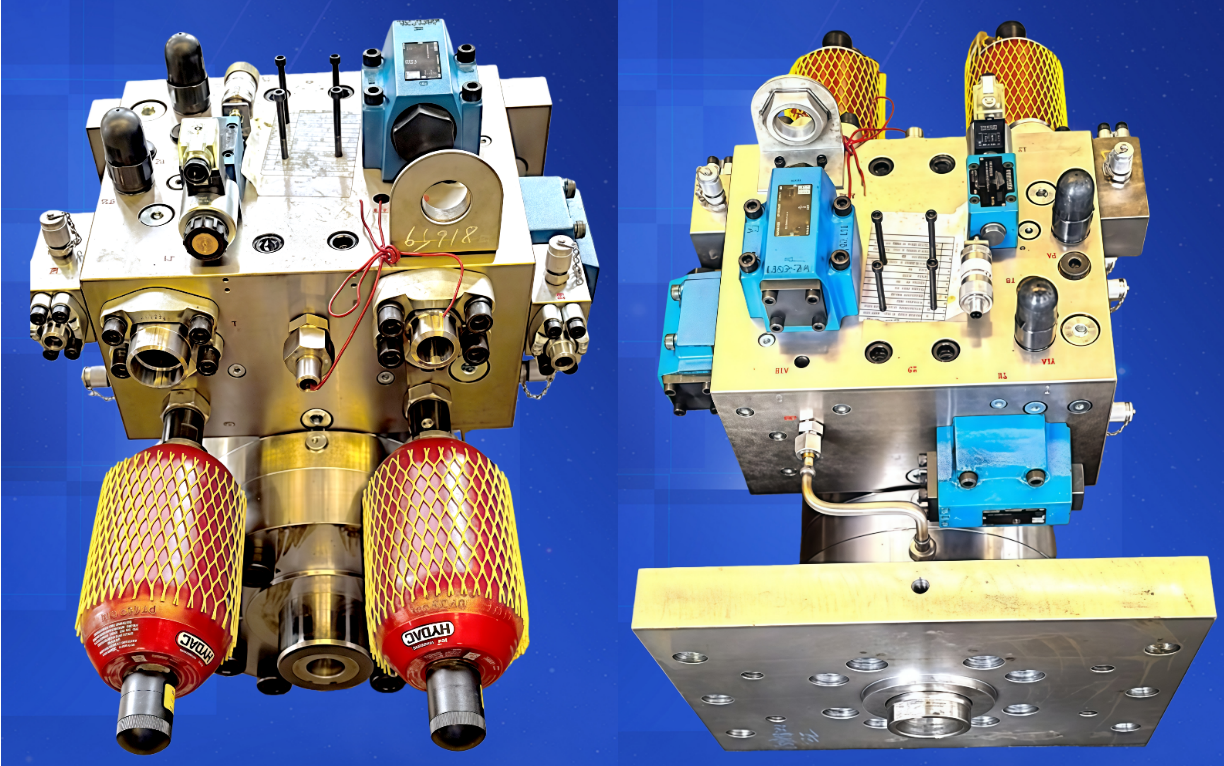

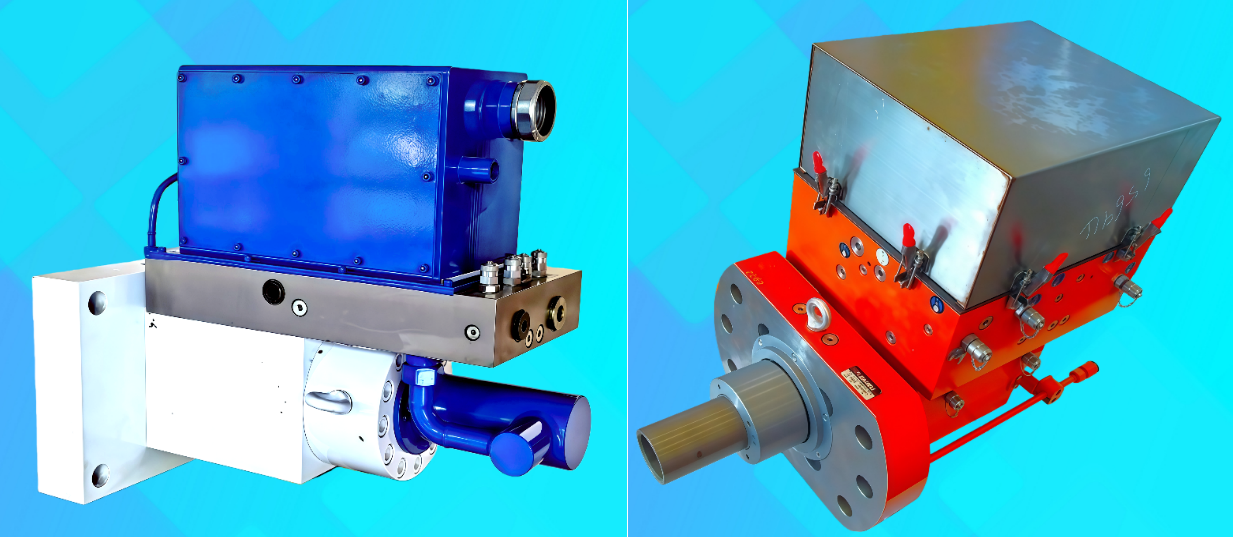

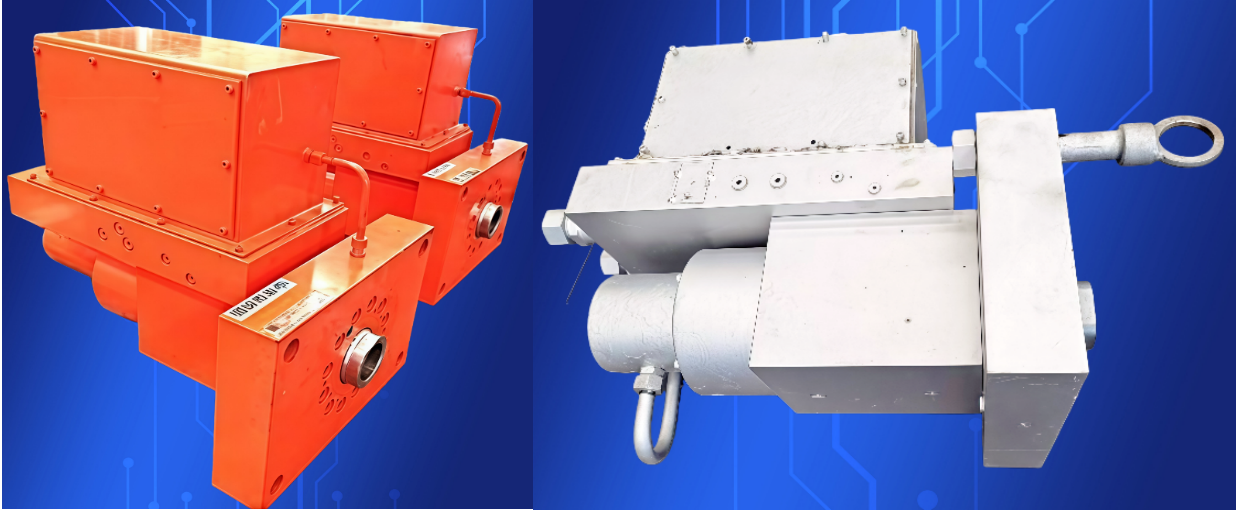

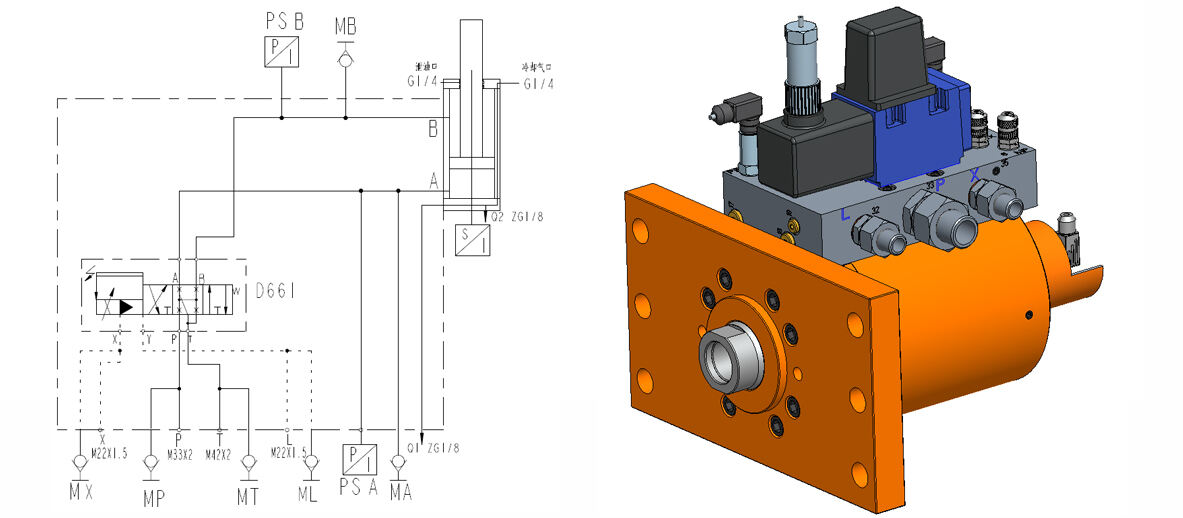

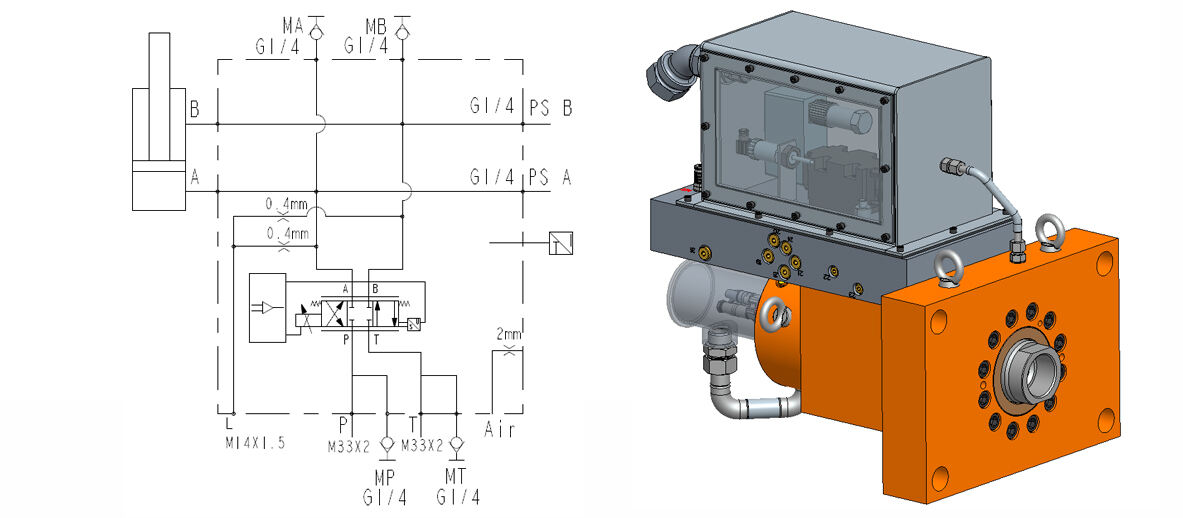

20 से अधिक वर्षों से, हमने 20 से अधिक प्रकार के सौं और अधिक मोल्ड ऑसिलेटिंग सिलिंडर उत्पादित किए हैं। नीचे हमारे कुछ मोल्ड ऑसिलेटिंग सिलिंडर के उदाहरण दिए गए हैं:

विशिष्ट मॉडल और विनिर्देश।

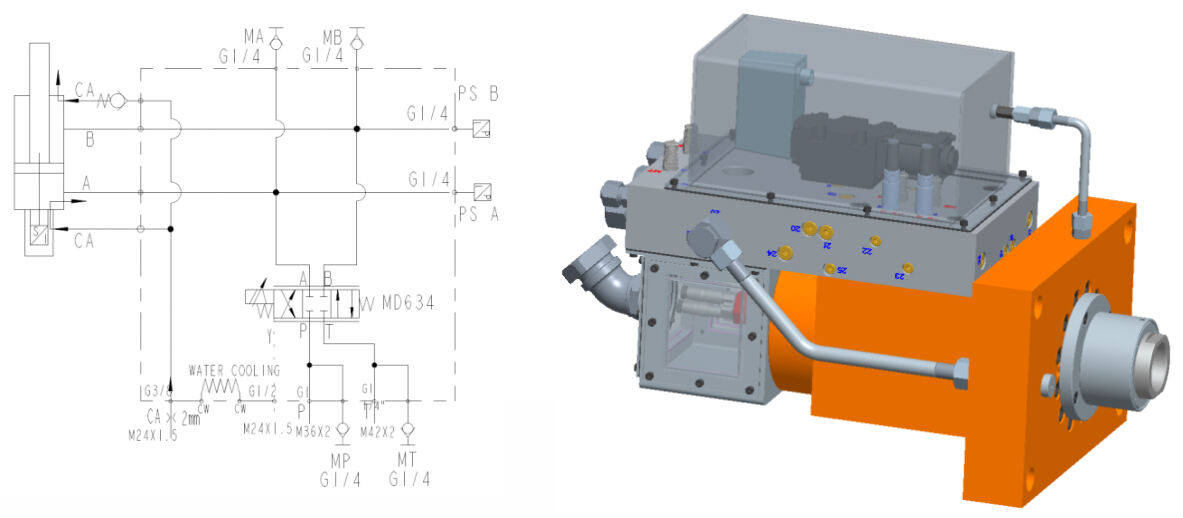

1.1、मॉडल: USYR2501R140/90-50LJHS+FK

・बोर 140 मिमी; रॉड 90 मिमी; स्ट्रोक 50 मिमी

・दबाव: कार्य 25 MPa; परीक्षण 31.5 MPa

・माध्यम: जल-ग्लाइकॉल; सील: FKM

・अंतर्निर्मित विस्थापन सेंसर; सर्वो वाल्व ब्लॉक

・सर्वो वाल्व: 75 लीटर/मिनट, अधिकतम 350 बार; 24V, ±10 mA, फीडबैक 4–20 mA

・सत्यापन: भार 4500 किग्रा, कंपन 193–325 OPM, प्रायोज्यता ±0.02 मिमी के भीतर

・गतिशील विशेषताएँ: अधिकतम सिग्नल मान का 25% 60 हर्ट्ज (9 ढलान रेखा)

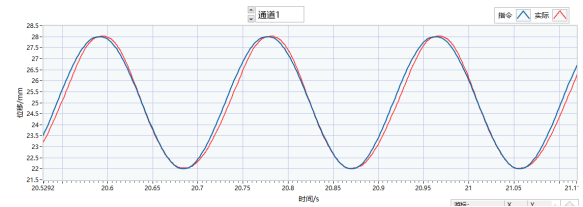

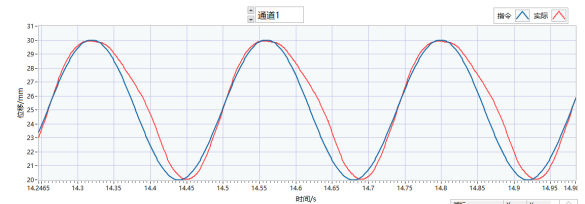

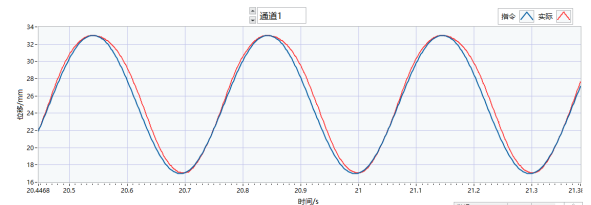

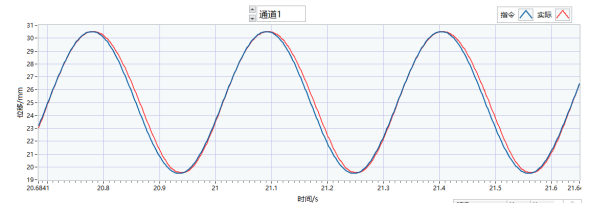

क्रिस्टलीकरण सर्वो कंपन हाइड्रोलिक सिलेंडर के लोड परीक्षण वक्र (भार: 4500 किग्रा)

1)कुल स्ट्रोक: 6मिमी (±3मिमी) ; दोलन आवृत्ति: 325 OPM;

प्रायोज्यता: ±0.025 ~ -0.02 मिमी। नीचे दिए गए चित्र को देखें।

2)कुल स्ट्रोक: 10मिमी (±5मिमी) ; दोलन आवृत्ति: 250 OPM;

प्रायोज्यता: ±0.07 ~ -0.02 मिमी। नीचे दिए गए चित्र को देखें

3) कुल स्ट्रोक: 16मिमी (±8मिमी); दोलन आवृत्ति: 200 OPM;

शुद्धता: ±0.015 ~ -0.05मिमी। नीचे दिए गए चित्र को देखें।

4) कुल स्ट्रोक: 11मिमी (±5.5मिमी); दोलन आवृत्ति: 193 OPM;

शुद्धता: ±0.015 ~ -0.05मिमी। नीचे दिए गए चित्र को देखें।

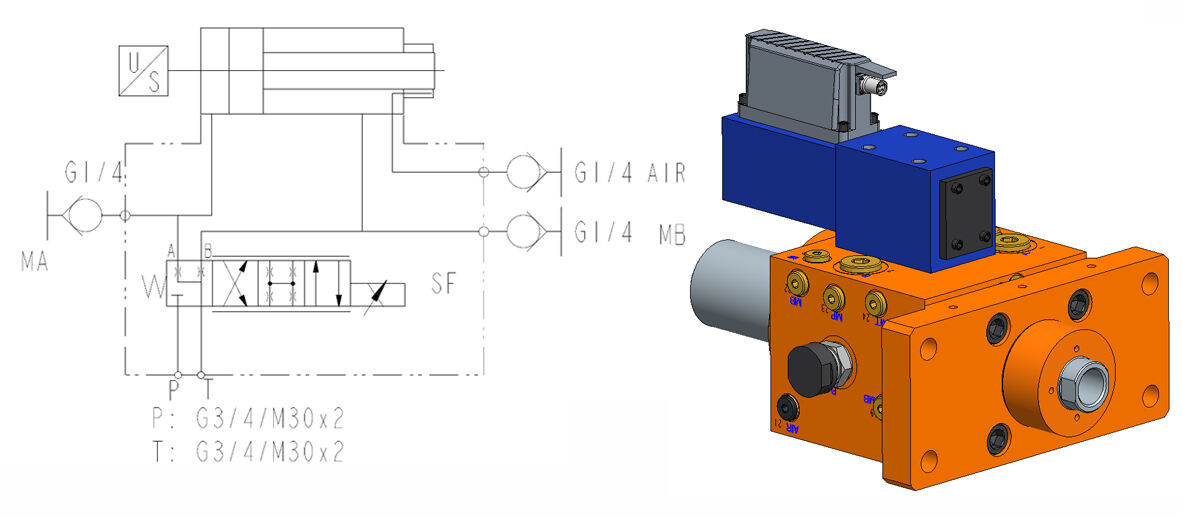

2、मॉडल: USYR2501R160/90-50LJHS+FK

・बोर 160 मिमी; रॉड 90 मिमी; स्ट्रोक 50 मिमी

・दबाव: कार्य 25 MPa; परीक्षण 31.5 MPa

・माध्यम: फैटी एस्टर; तापमान −10℃~+80℃

・अंतर्निर्मित विस्थापन सेंसर;