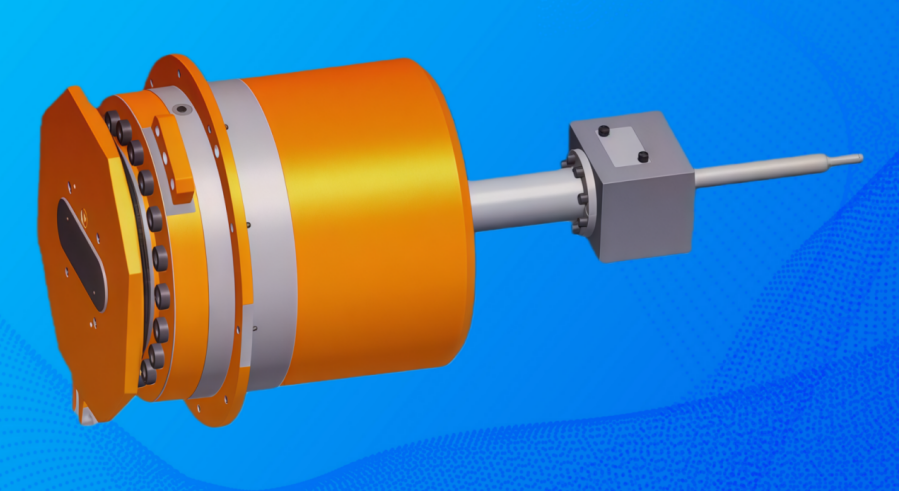

Les cylindres hydrauliques servo AGC utilisent un design de URANUS, incorporant des joints pour cylindres hydrauliques servo.

Le barillet du cylindre est usiné à partir d'acier 42CrMO forgé, trempé et revenu.

La surface intérieure est plaquée au chrome dur avec une épaisseur de revêtement de 0,08-0,10 mm et une dureté de Hv800-900.

La tige du piston est fabriquée en acier 42CrM0 forgé, trempé et revenu. La surface est plaquée au chrome dur avec une épaisseur de revêtement supérieure ou égale à 0,08-0,10 mm, et une dureté de Hv800-900.

Le test en usine est effectué à l'aide d'une plateforme de test spécialisée pour les cylindres hydrauliques servo AGC.

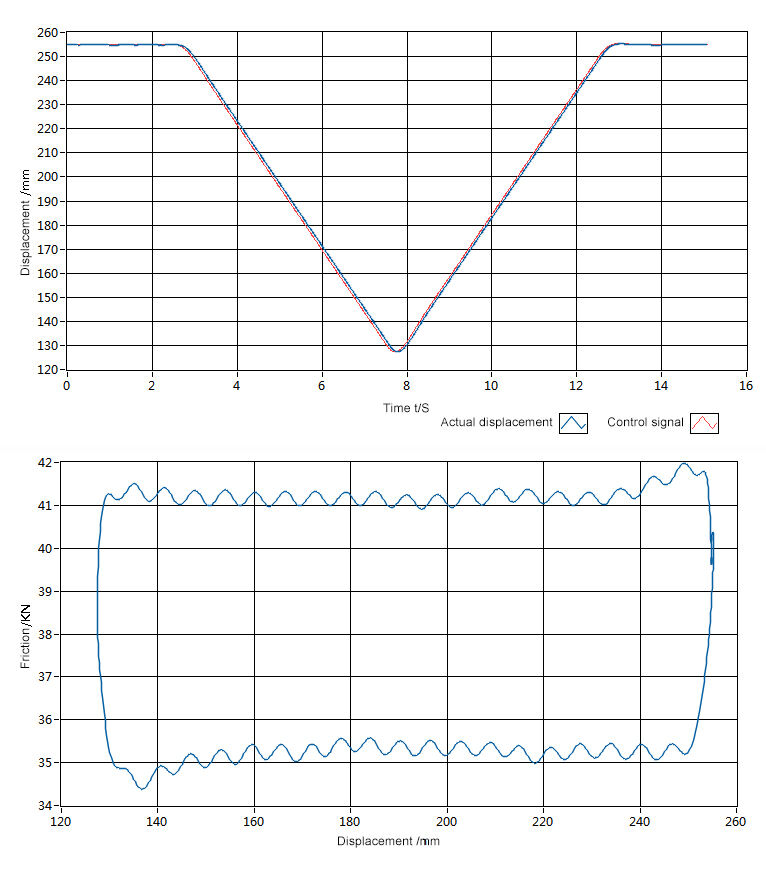

Test de performance de frottement ; fournit des courbes de frottement dynamique et statique.

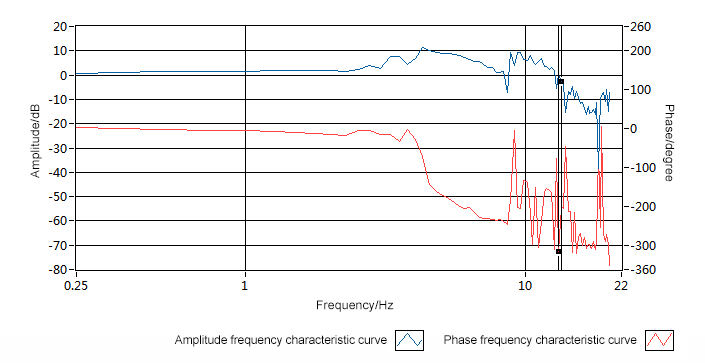

Test de performance dynamique ; fournit des diagrammes de réponse en escalier et des diagrammes fréquentiels logarithmiques en boucle fermée.

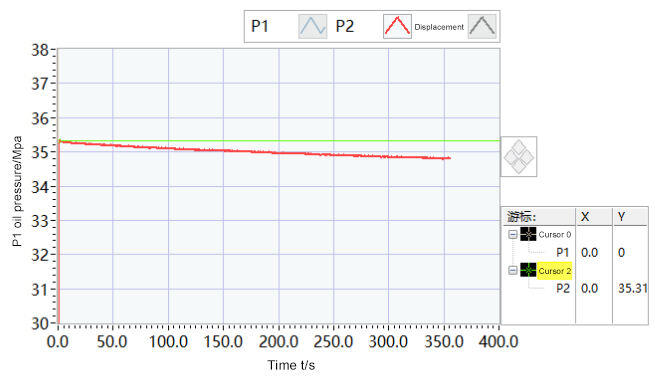

Test de fuite interne ; mesure la baisse de pression sous conditions de pression nominale (≤ 0,5 MPa) et fournit un diagramme de test de maintien de pression.

Test de propreté de l'huile ; ≥ NAS5 ou supérieur

Pression de démarrage minimale (≤ 0,05 Mpa)

Pression de test ; 1,5 fois la pression nominale

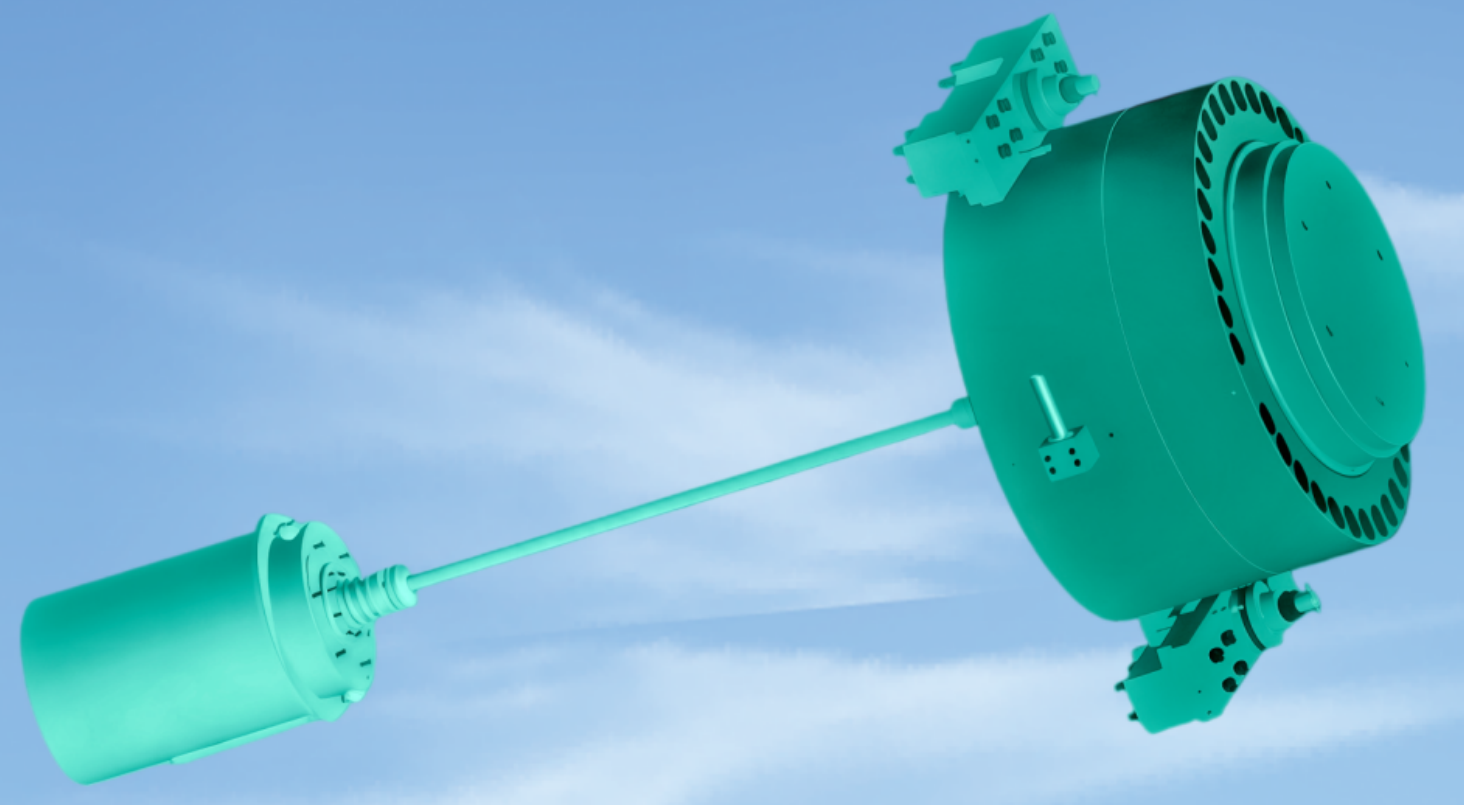

Types optionnels de capteurs de déplacement :

Capteurs de déplacement intégrés/externes/magnétiques de MTS, BALLUFF ou TR disponibles en option.

Capteur à échelle magnétique SONY, capteur de déplacement LVDT,

Bloc de valve servo, capteur de pression, raccord d'échappement et de mesure de pression optionnels pour l'extrémité de la cavité sans tige ;

Support sphérique, pare-poussière accordéon et bouclier thermique métallique optionnels pour l'extrémité du piston.

Le cylindre servo a une garantie de 1 à 5 ans selon le type.

Plus de 1000 cylindres hydrauliques servo de la série AGC ont été fournis à des clients dans le monde entier.

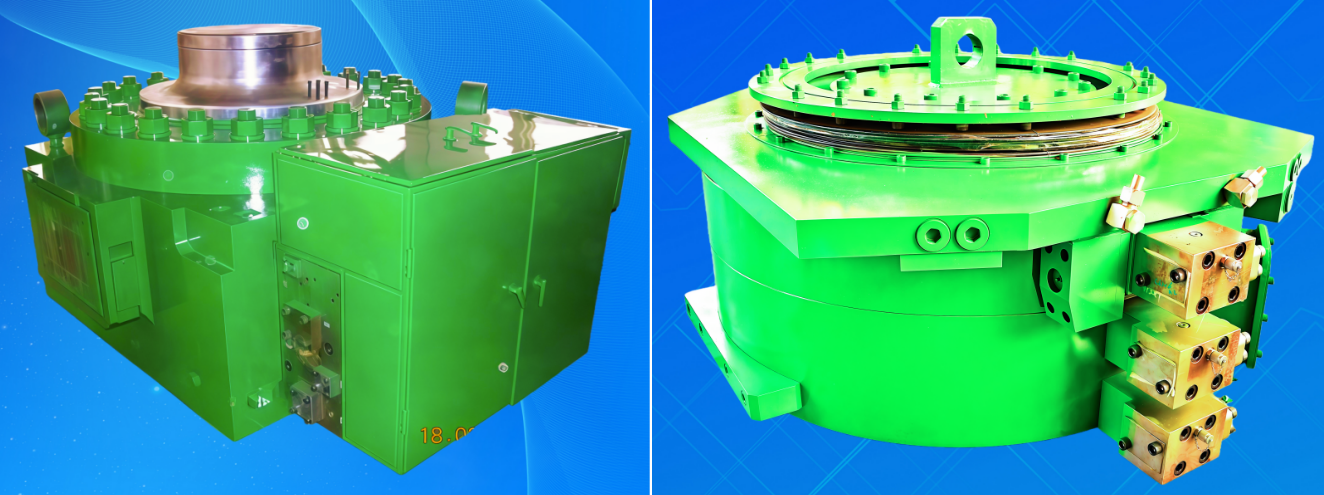

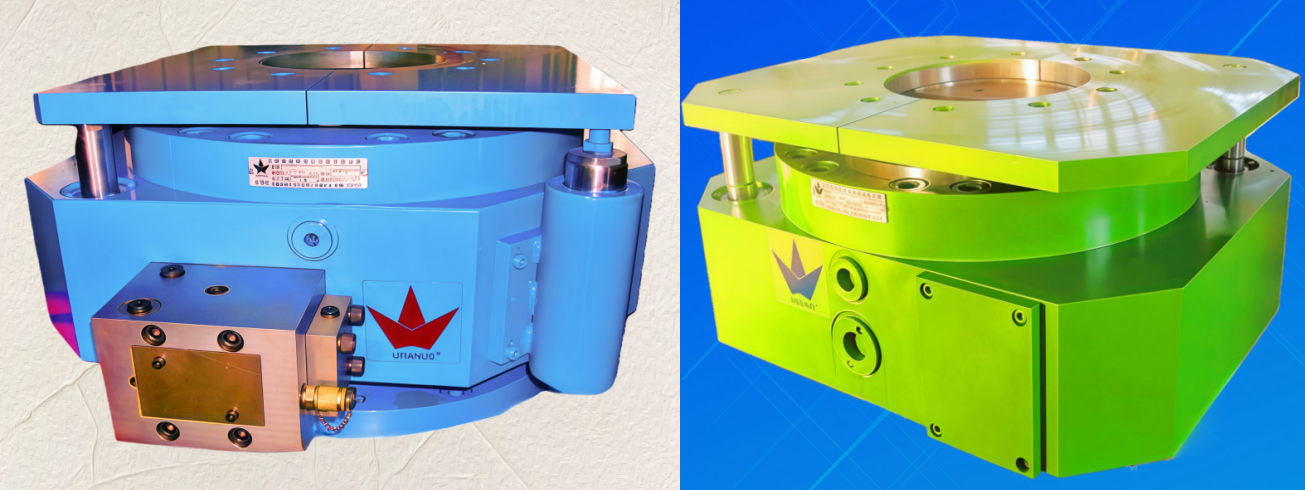

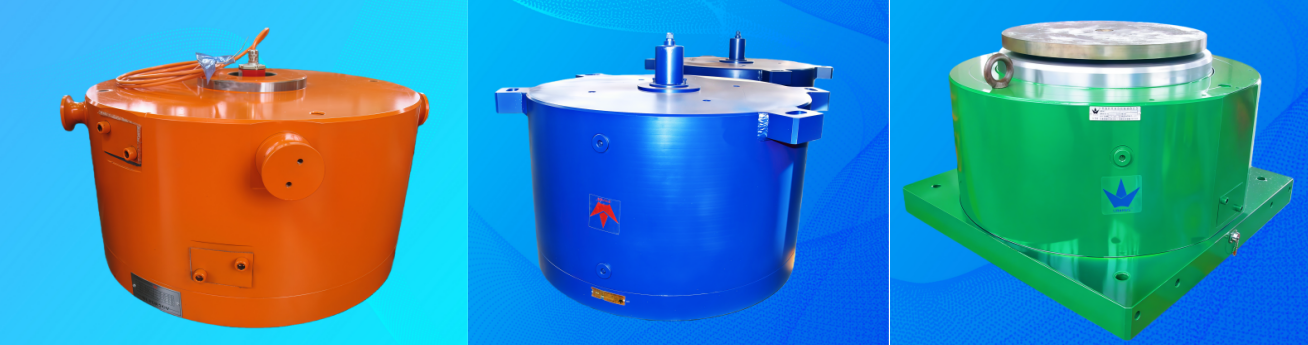

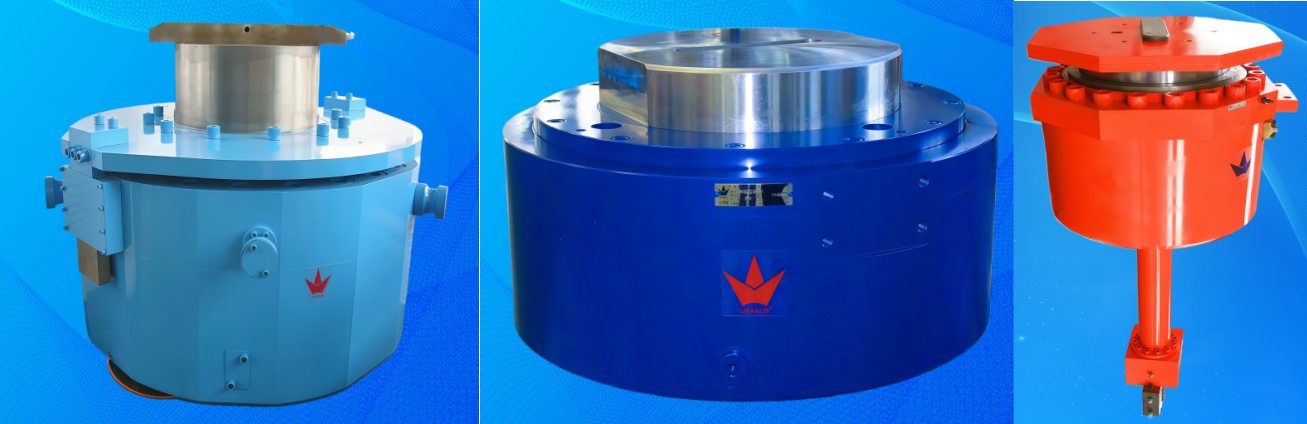

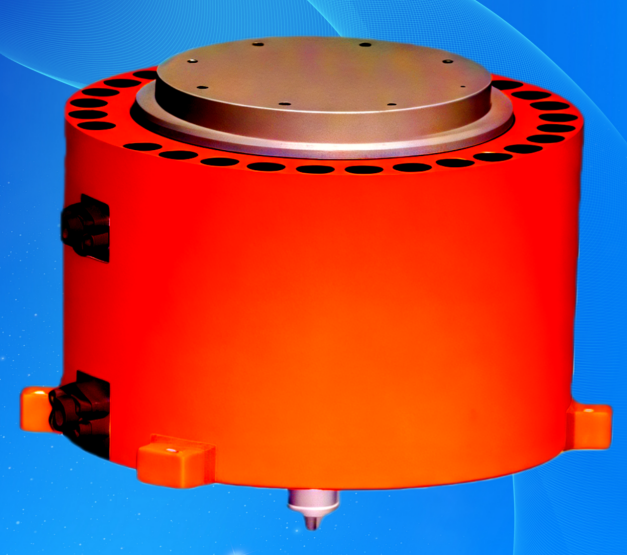

Cylindre hydraulique servo AGC

Cylindre de commande automatique d'épaisseur

Uranus Hydraulic Machinery Co., Ltd.

Un fabricant chinois de premier plan de vérins hydrauliques servo haute pression et haute précision, equipé de La plus grande plateforme chinoise de test de cylindres AGC de 8000 tonnes.

1. Présentation du produit

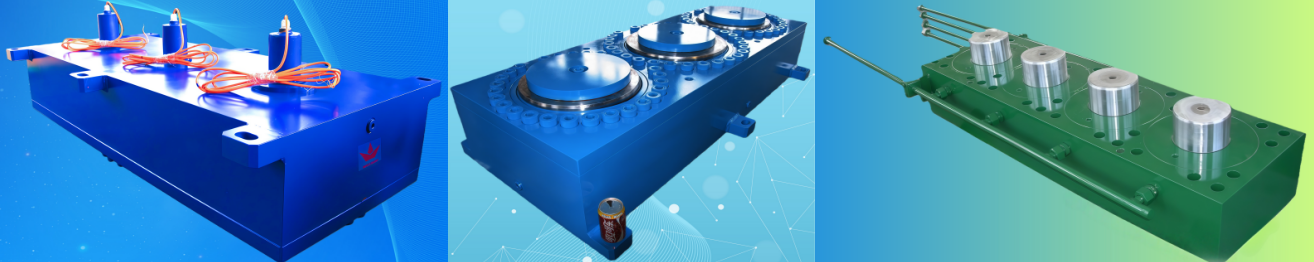

Le vérin hydraulique servo AGC est l'actionneur principal des systèmes de commande automatique d'épaisseur (AGC) dans les laminoirs à acier.

Il ajuste précisément l'entrefer des cylindres par une commande électro-hydraulique en boucle fermée, garantissant une épaisseur stable de la bande à la sortie du laminoir.

Les signaux de déplacement, de pression et d'épaisseur forment une rétroaction en boucle fermée. Le contrôleur les traite via un algorithme PID et commande la vanne servo pour assurer un contrôle de l'entrefer au micron près, mettant en vedette haute précision, réponse rapide et excellente stabilité.

Applications :

• Tréfileries à chaud

• Tréfileries à froid

• Laminage de finition / laminage à froid léger

• Lignes de bandes en acier inoxydable, acier au silicium, aluminium, cuivre

2. Avantages techniques

Compétences solides en ingénierie et en R&D

• Plus de 40 ingénieurs concepteurs

• Plus de 30 ans d'expertise en cylindres AGC

• Des milliers de cylindres AGC livrés dans le monde entier

Disponible Pour Fabricant d'équipements d'origine basé sur plans ou conception sur mesure.

Configurations flexibles

Capteurs

• Capteurs de pression / force

• Capteurs magnétostrictifs internes ou externes

• Échelle magnétique / échelle optique

• Capteurs de déplacement LVDT

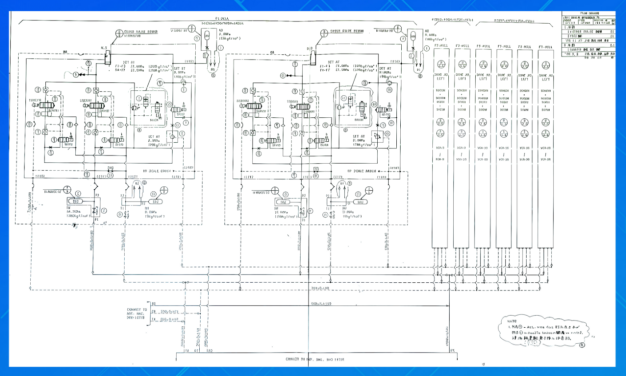

Options de valve

• Vannes servo (MOOG)

• Vannes bloc-hublot / cartouche

• Raccords de test de pression et de purge d'air

Options structurelles

• Roulement sphérique

• Couvercle de protection métallique / soufflet

3. Fabrication et assurance qualité

Tous les cylindres sont conformes à :

• GB/T 32216-2015 (Méthode d'essai pour vérins proportionnels/servo)

• DIN ISO 10100:2022 (Essai de réception des vérins hydrauliques)

inspection à 100 % de tous les composants avec archivage des relevés pendant plus de 10 ans.

Procédé principal de fabrication

Carter Cylindrique

• Forge en 42CrMo, testé par ultrasons

• Alésage et rectification de précision

• Plaqué chrome dur ≥0,08 mm, HV ≥800

• Rugosité de surface ≤ Ra0,4 μm

Tige du piston

• 42CrMo trempé et revenu

• Plaqué chrome dur ≥0,08 mm

• Rugosité ≤ Ra0,2 μm

Scellés

• Joints servo haute pression, basse friction (PTFE + NBR)

• Assemblage en salle propre

4. Tests complets (courbes fournies)

Tests statiques

pression nominale à 1,5×, maintien pendant 10 min

• Aucune déformation permanente et aucune fuite

• Fuite interne ≤ baisse de 1 MPa en 5 min

• Pression de démarrage ≤ 0,01 MPa

• Variation de friction ≤ ±5 %

Essais dynamiques

• Temps de réponse en marche ≤ 25–50 ms

• Dépassement ≤ 10–15 %

• Bande passante en fréquence ≥ 10 Hz

• Précision de position ≤ ±0,005 mm

Banc d'essai (le plus grand en Chine)

• Charge de poussée-traction de 8000 tonnes

• Puissance hydraulique de 35 MPa, 1000 L/min

• Servovalve MOOG 792

• Précision de déplacement ±0,01 mm

5. Fiabilité

Durée de vie sans défaillance :

1–5 ans (≥ 1 000 000 cycles)

Tableau des paramètres techniques du vérin hydraulique servo AGC

| Diamètre du cylindre | Diamètre de la tige | Force de travail à différentes pressions de fonctionnement (KN) | Diamètre du cylindre | Diamètre de la tige | Force de travail à différentes pressions de fonctionnement (KN) | ||||||||

| 10Mpa | 16 MPa | 21 MPa | 25MPa | 28Mpa | 10Mpa | 16 MPa | 21 MPa | 25MPa | 28Mpa | ||||

| 300 | 260 | 707 | 1131 | 1484 | 1767 | 1979 | 800 | 750 | 5027 | 8042 | 10556 | 12566 | 14074 |

| 350 | 300 | 962 | 1539 | 2020 | 2405 | 2694 | 860 | 800 | 5809 | 9294 | 12199 | 14522 | 16265 |

| 360 | 320 | 1018 | 1629 | 2138 | 2545 | 2850 | 900 | 840 | 6362 | 10179 | 13360 | 15904 | 17813 |

| 380 | 340 | 1134 | 1815 | 2382 | 2835 | 3176 | 1000 | 900 | 7854 | 12566 | 16493 | 19635 | 21991 |

| 400 | 1257 | 2011 | 2639 | 3142 | 3519 | 1050 | 8659 | 13854 | 18184 | 21648 | 24245 | ||

| 420 | 360 | 1385 | 2217 | 2909 | 3464 | 3879 | 1100 | 1000 | 9503 | 15205 | 19957 | 23758 | 26609 |

| 450 | 400 | 1590 | 2545 | 3340 | 3976 | 4453 | 1200 | 1100 | 11310 | 18096 | 23750 | 28274 | 31667 |

| 480 | 420 | 1810 | 2895 | 3800 | 4524 | 5067 | 1300 | 1200 | 13273 | 21237 | 27874 | 33183 | 37165 |

| 500 | 450 | 1964 | 3142 | 4123 | 4909 | 5498 | 1400 | 1300 | 15394 | 24630 | 32327 | 38485 | 43103 |

| 550 | 500 | 2376 | 3801 | 4989 | 5940 | 6652 | 1450 | 1350 | 16513 | 26421 | 34677 | 41283 | 46236 |

| 600 | 550 | 2827 | 4524 | 5937 | 7069 | 7917 | 1500 | 1400 | 17671 | 28274 | 37110 | 44179 | 49480 |

| 620 | 580 | 3019 | 4831 | 6340 | 7548 | 8453 | 1600 | 1500 | 20106 | 32170 | 42223 | 50265 | 56297 |

| 650 | 3318 | 5309 | 6968 | 8296 | 9291 | 1700 | 1600 | 22698 | 36317 | 47666 | 56745 | 63554 | |

| 700 | 640 | 3848 | 6158 | 8082 | 9621 | 10776 | 1800 | 1700 | 25447 | 40715 | 53439 | 63617 | 71251 |

| 720 | 660 | 4072 | 6514 | 8550 | 10179 | 11400 | 1900 | 1800 | 28353 | 45365 | 59541 | 70882 | 79388 |

| 760 | 700 | 4536 | 7258 | 9527 | 11341 | 12702 | 2000 | 1900 | 31416 | 50265 | 65973 | 78540 | 87965 |

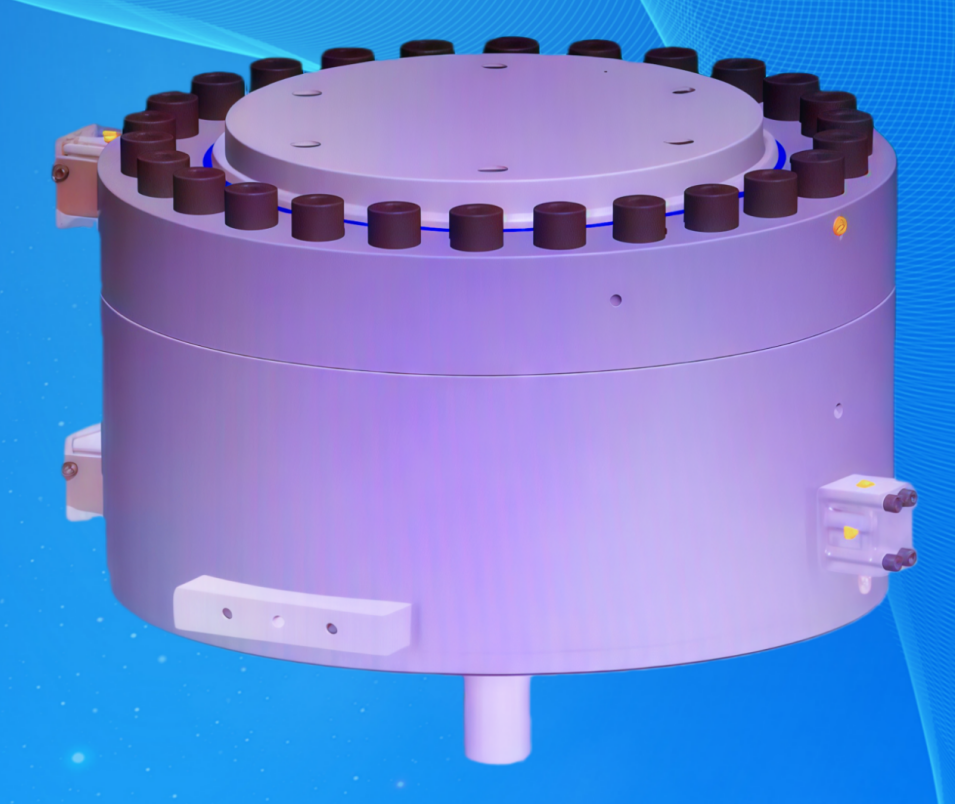

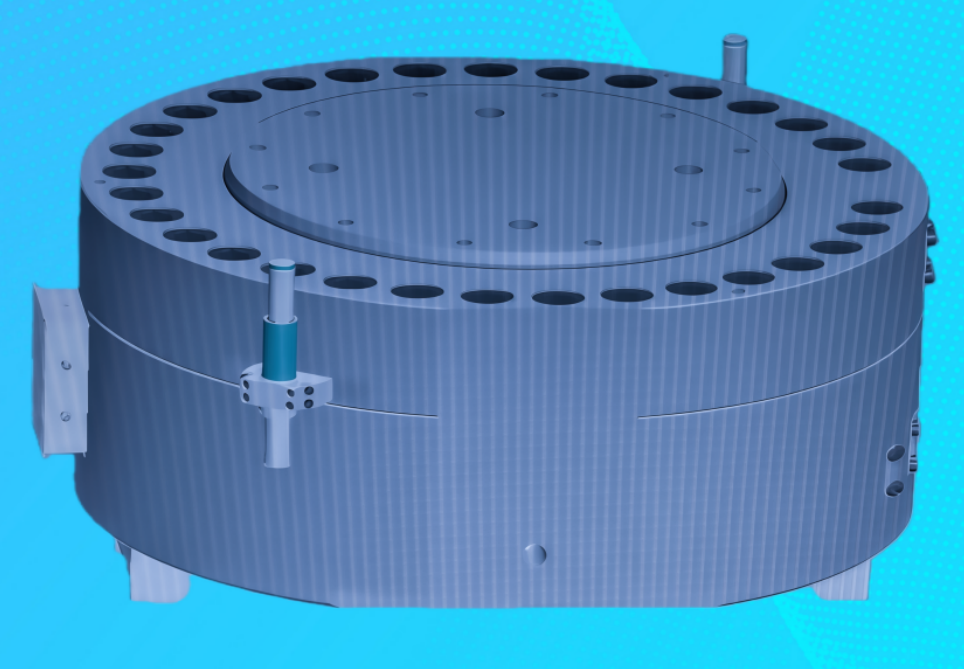

6. Exemples de projets types

1. Nom : Vérin hydraulique servo AGC ; Modèle : UAGCT940/860-148 SONY

Alésage : 940, Tige : 860, Course : 148 ; Échelle magnétique externe SONY

Pression de travail : 28 MPa, Pression d'essai : 35 MPa

2. Nom : Vérin hydraulique servo AGC ; Modèle : UAGC800/740-210

· Alésage : 800, Tige : 740, Course : 210 ; Pression de travail : 25 MPa, Pression d'essai : 37,5 MPa

3. Nom : Vérin hydraulique servo AGC ; Modèle : UAGC1600/1450-85H

· Alésage : 1600, Tige : 1450, Course : 85

· Pression de travail de la chambre sans tige : 27 MPa, Pression d'essai : 37,5 MPa

· Pression de travail de la chambre à tige : 7 MPa, Pression d'essai : 10 MPa

· Fluide de travail : N46 · Capteur de déplacement externe

4. Nom : Vérin hydraulique servo AGC à dix-huit rouleaux 1450 ; Modèle : UAGC760/680-180H

· Alésage : 760, Tige : 680, Course : 180 ; Pression de travail : 21 MPa, Pression d'essai : 31 MPa

· Fluide de travail : N46 · Capteur interne de déplacement

5. Nom : Vérin hydraulique servo AGC pour polisseuse ; Modèle : UAGC560/480-385

· Alésage : 560, Tige : 480, Course : 385 ; Pression de travail : 23 MPa, Pression d'essai : 34,5 MPa

· Fluide de travail : Huile hydraulique

6. Nom : Vérin hydraulique servo AGC pour laminoir finisseur 1580 F4-F7 ; Modèle : UST1050/900-170CL(DS)

· Alésage : 1050, Tige : 900, Course : 170 ;

· Pression de démarrage ≤ 0,05 MPa, Fuite interne ≤ 15 ml/min, Aucune fuite externe

· Pression de travail de la chambre sans tige : 30,9 MPa, Pression d'essai : 35 MPa

· Pression de travail de la chambre de tige : 6,86 MPa, pression d'essai : 10 MPa

· Largeur de bande ≥15 Hz ; échelle magnétique interne SONY

| Nom | Cylindre hydraulique AGC 23010105008 | Modèle acheteur | 940/860-148 | NUMÉRO D'USINE | 158207 | ||||

| Modèle du fournisseur | Modèle du fournisseur | UAGC2306T940\/860-148SONY | |||||||

| Diamètre du cylindre | 940 mm | Diamètre de la tige | 860 mm | Course | 148 mm | Pression nominale | 28 Mpa | Température de l'huile | 50±5°C |

| Huile de test | Huile hydraulique anti-usure N46# | Propreté de l'huile | Température ambiante. | 35°C | |||||

| Élément de Test | Résultats des tests | ||||||||

| Fonctionnement en mode sentier | Mouvement réciproque complet 10 fois. Lorsque la vitesse est ≤ 5mm/s, vérifiez les phénomènes de rampe, de vibration, etc. | N/A | |||||||

| Vérification complète de l'amplitude | Amplitude mesurée | 148mm | |||||||

| Effet d'amortissement | N/A | ||||||||

| Pression de démarrage minimale | Chambre sans tige | 0,016 Mpa | Chambre à tige | 0.01MPa | |||||

| Fuite interne | Chambre sans tige | Pression | 28Mpa | Temps | 10min | Réussi | |||

| Chambre sans tige | Pression | 28Mpa | Temps | 10min | Réussi | ||||

| Test de résistance à la tension | Chambre sans tige | Pression | 35MPa | Temps | 5min | Réussi | |||

| Chambre sans tige | Pression | 35MPa | Temps | 5min | Réussi | ||||

| Inspection des fuites externes | Processus de test | Tige du piston | Autres pièces | ||||||

| N/A | N/A | ||||||||

| Test de frottement dynamique et statique |  |

||||||||

|

Test de performance dynamique Logarithme en boucle fermée Caractéristiques fréquentielles |

|

||||||||

| Test de maintien de la pression statique |  |

||||||||

| Remarques | |||||||||

| Instructions |

1. Ce rapport est un enregistrement du site d'essai et ne doit pas être rédigé a posteriori. 2. Le cylindre différentiel détecte uniquement la pression minimale de démarrage de la chambre sans tige ; le cylindre à double tige détecte la pression minimale de démarrage de la chambre avec tige d'un côté. 3. Ce rapport n'est pas valide sans la signature et le sceau officiel du personnel d'inspection à temps plein de l'entreprise. |

||||||||

| Testé par : | Révisé par : | Date de l'essai : août 2024 | |||||||

| (Sceau officiel) | |||||||||