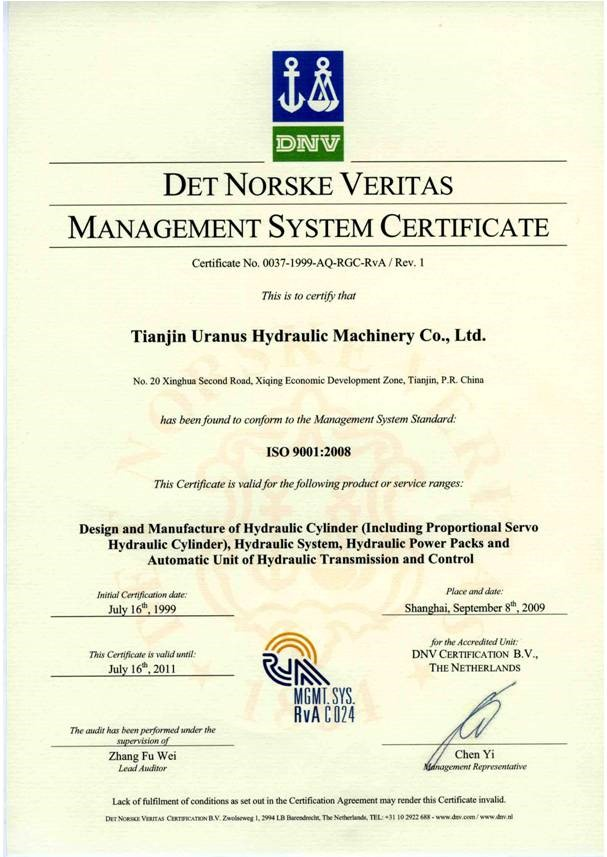

In the competitive global hydraulic cylinder market, quality is the cornerstone of customer trust and long-term business success. Tianjin Uranus Hydraulic Machinery Co., Ltd., a leading custom hydraulic cylinder manufacturer with over 30 years of industry expertise, has firmly established its reputation for excellence by adhering to stringent international standards—specifically, through its acquisition and strict implementation of key ISO certifications. These certifications not only validate the company’s commitment to quality but also ensure that every custom hydraulic cylinder it produces meets or exceeds global performance, environmental, and safety requirements.

Founded in 1992, Tianjin Uranus has grown from a regional player to a globally recognized hydraulic solutions provider, boasting titles such as "National Small Giant Enterprise," "National High-Tech Enterprise," and "National Intellectual Property Advantage Enterprise." With a 45,000-square-meter production base, a registered capital of 65 million yuan, and an annual output value of 200-300 million yuan, the company has the scale and resources to deliver custom hydraulic cylinders for diverse industries, including metallurgy, heavy machinery, marine engineering, and aerospace. However, it is Tianjin Uranus’ unwavering focus on quality—backed by ISO certifications—that sets it apart from competitors.

At the heart of Tianjin Uranus’ quality assurance system lies its ISO 9001:2015 certification (Quality Management System). This globally recognized standard is not merely a document for the company; it is a framework integrated into every stage of the custom hydraulic cylinder manufacturing process. From the initial client consultation to the final product delivery, ISO 9001:2015 guides Tianjin Uranus’ operations:

- Design Phase: When developing custom cylinders based on client specs (e.g., load capacity, temperature resistance, or dimensional requirements), the R&D team uses ISO 9001-compliant design controls. This includes cross-functional reviews, risk assessments, and validation tests to ensure the design aligns with client needs and industry standards. For instance, when creating a custom AGC servo cylinder for a steel mill, the team referenced ISO 9001 protocols to verify material selections (e.g., high-strength alloys) and simulate performance under extreme rolling conditions.

- Production Phase: The manufacturing floor operates in strict accordance with ISO 9001 procedures. This includes real-time monitoring of key processes (e.g., forging, machining, and assembly), regular equipment calibration, and detailed record-keeping of every production step. Each component—from piston rods to seals—undergoes dimensional inspection and material testing to prevent defects. For example, Tianjin Uranus uses coordinate measuring machines (CMMs) to check cylinder bore accuracy within ±0.005mm, a standard enforced by ISO 9001 to ensure consistent performance.

- Testing & Delivery: Before shipping, every custom hydraulic cylinder undergoes comprehensive ISO 9001-mandated tests, such as pressure testing (up to 1.5 times the rated pressure), leakage testing, and durability cycling. Only products that pass all tests receive a certificate of compliance, providing clients with tangible proof of quality.

Complementing ISO 9001, Tianjin Uranus holds ISO 14001:2015 certification (Environmental Management System), which reflects its commitment to sustainable manufacturing—an increasingly critical factor for global clients. In the production of custom hydraulic cylinders, the company minimizes environmental impact by optimizing resource use (e.g., recycling metal scraps from machining processes, reducing water consumption in cooling systems) and controlling emissions (e.g., using low-VOC lubricants and installing dust collection systems in forging areas). For example, when manufacturing large-scale ladle lifting cylinders for metallurgy clients, Tianjin Uranus’ ISO 14001-compliant processes reduced waste by 18% and energy consumption by 12% compared to non-certified methods. This not only benefits the environment but also lowers production costs, allowing the company to offer competitive pricing on high-quality custom solutions.

Equally important is Tianjin Uranus’ ISO 45001:2018 certification (Occupational Health and Safety Management System), which ensures a safe working environment for employees—a factor that directly impacts product quality. A well-trained, safe workforce is more likely to adhere to precision manufacturing standards and avoid errors. The company implements ISO 45001 protocols such as regular safety training (e.g., handling heavy machinery, working with high-pressure systems), personal protective equipment (PPE) requirements, and routine workplace risk assessments. For instance, in the assembly of ultra-high-pressure hydraulic cylinders (up to 130MPa), workers follow ISO 45001-approved procedures for pressure testing, including using blast shields and calibrated safety valves. This focus on safety reduces downtime from accidents and ensures consistent, high-quality output.

Tianjin Uranus’ ISO certifications are not static achievements; the company undergoes annual audits by accredited third-party bodies to maintain compliance, continuously updating its processes to meet evolving standard requirements. This dedication to continuous improvement is reflected in its 50+ patents (27 invention patents, 23 utility model patents) and 38 independently developed product series—7 of which meet national JB/ZQ heavy machinery standards. For example, a European heavy machinery client recently partnered with Tianjin Uranus for custom gear-rack swing cylinders, citing the company’s ISO certifications as a key reason for selection. The client required cylinders that met strict EU safety and environmental regulations, and Tianjin Uranus’ ISO-compliant processes ensured the products not only met but exceeded these requirements, leading to a long-term collaboration.

In an era where clients demand transparency, reliability, and compliance, Tianjin Uranus Hydraulic Machinery Co., Ltd. leverages ISO 9001, ISO 14001, and ISO 45001 certifications to deliver custom hydraulic cylinders of uncompromising quality. Its ability to integrate these standards into every aspect of operations—from design to delivery—makes it a trusted partner for businesses worldwide.

If you are seeking a custom hydraulic cylinder manufacturer that guarantees quality through internationally recognized certifications, look no further than Tianjin Uranus. Contact the team today at +86-022-83989131 or [email protected] to discuss your custom requirements and experience the peace of mind that comes with ISO-certified quality.