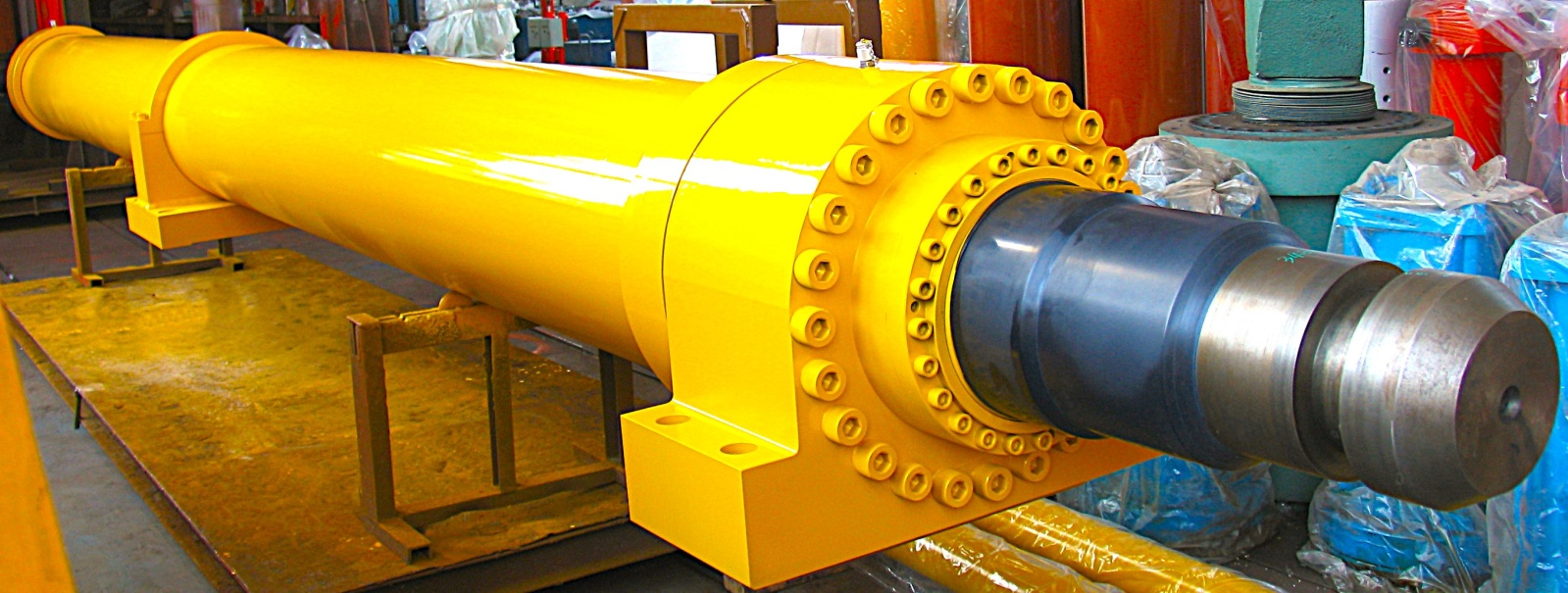

In industries ranging from aerospace to marine engineering, the demand for high-pressure hydraulic cylinders capable of withstanding extreme environments is constantly growing. Tianjin Uranus Hydraulic Machinery Co., Ltd., a leading player in the hydraulic equipment industry since 1992, has emerged as a trusted custom hydraulic cylinder manufacturer, specializing in the development of high-pressure cylinders that excel in the most challenging conditions.

With a strong foundation built over three decades, Tianjin Uranus has earned prestigious titles such as "National Small Giant Enterprise," "National High-Tech Enterprise," and "National Intellectual Property Advantage Enterprise." The company boasts a 45,000-square-meter production base, a registered capital of 65 million yuan, and an annual output value of 200-300 million yuan. These resources, combined with certifications including ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018, enable Tianjin Uranus to deliver high-quality, reliable hydraulic solutions to global clients.

At the core of Tianjin Uranus' success is its unwavering commitment to research and development. The company houses a top-tier R&D team that has filed approximately 50,000 sets of drawings for non-standard products. It holds 27 invention patents and 23 utility model patents, with plans to add 7 more patents in 2024. Independently developing 38 product series, 7 of which have been recognized as JB/ZQ heavy machinery standards by the National Bureau of Standards, Tianjin Uranus has the technical expertise to tackle the unique challenges of high-pressure cylinder development for extreme environments.

One remarkable example of high-pressure cylinder innovation is the 130MPa booster cylinder and ultra-high-pressure hydraulic cylinder. In the oil and gas industry, where equipment must operate under extreme pressure to extract resources from deep underground, a leading hydraulic technology firm developed these specialized cylinders. The 130MPa booster cylinder is designed to amplify pressure, enabling efficient oil extraction in deep wells. The ultra-high-pressure hydraulic cylinder, with its robust structure and advanced sealing technology, can withstand the intense pressure levels encountered in downhole operations. These cylinders have significantly improved the efficiency and safety of oil and gas extraction, even in the harshest underground environments.

Extreme temperatures present another major challenge for hydraulic cylinders. In a steel mill in northern China, where the environment temperature reaches 1000℃ during production, a custom high-temperature cylinder with a water-cooling jacket and stainless steel protective cover was deployed for hood lifting. The water-cooling jacket circulates cooling water to keep the cylinder's internal components within a safe operating temperature range, while the stainless steel protective cover shields the cylinder from direct heat radiation and physical damage. This specialized cylinder ensures smooth and reliable hood lifting operations, even in the scorching heat of the steel mill, minimizing downtime and improving production efficiency.

Corrosive environments, such as those in marine and chemical industries, require hydraulic cylinders with exceptional resistance to acids, alkalis, and seawater. A hydraulic equipment manufacturer developed a ceramic piston rod hydraulic cylinder to meet this demand. The ceramic coating on the piston rod provides a dense, non-porous surface that is highly resistant to corrosion. In a coastal desalination plant, these cylinders have been in operation for over five years, showing no signs of corrosion or performance degradation. They effectively withstand the corrosive effects of seawater and chemical additives used in the desalination process, ensuring long-term reliable operation of the plant's hydraulic systems.

In the aerospace and defense sectors, speed is often a critical requirement. For drone catapults, which need to accelerate drones to high speeds in a short time, a manufacturer developed a 36m/s ultra-high-speed hydraulic cylinder. This cylinder features a lightweight yet strong structure, advanced valve control technology, and high-flow hydraulic circuits. During testing, it successfully accelerated a 500kg drone to 36m/s within 2 seconds, meeting the strict performance requirements of drone launch systems. The ultra-high-speed cylinder's reliability and precision make it an essential component in modern drone catapult technology.

Tianjin Uranus Hydraulic Machinery Co., Ltd. draws on its extensive experience, advanced technology, and strong R&D capabilities to develop custom high-pressure hydraulic cylinders for extreme environments. Equipped with ERP, 3D design software, and PDM systems, the company ensures efficient product development, production, and quality control. Its products are exported to more than 20 countries and regions, including the United States, Germany, and Japan, earning a reputation for excellence in the global market.

As industries continue to push the boundaries of what is possible, the need for high-pressure hydraulic cylinders that can withstand extreme environments will only increase. Tianjin Uranus Hydraulic Machinery Co., Ltd. is well-positioned to meet this demand, providing custom solutions that combine performance, reliability, and durability. Whether it's for ultra-high-pressure applications, extreme temperatures, corrosive environments, or high-speed operations, Tianjin Uranus is the partner you can trust. Contact them today at +86-022-83989131 or via email at [email protected] to learn more about their high-pressure hydraulic cylinder solutions.